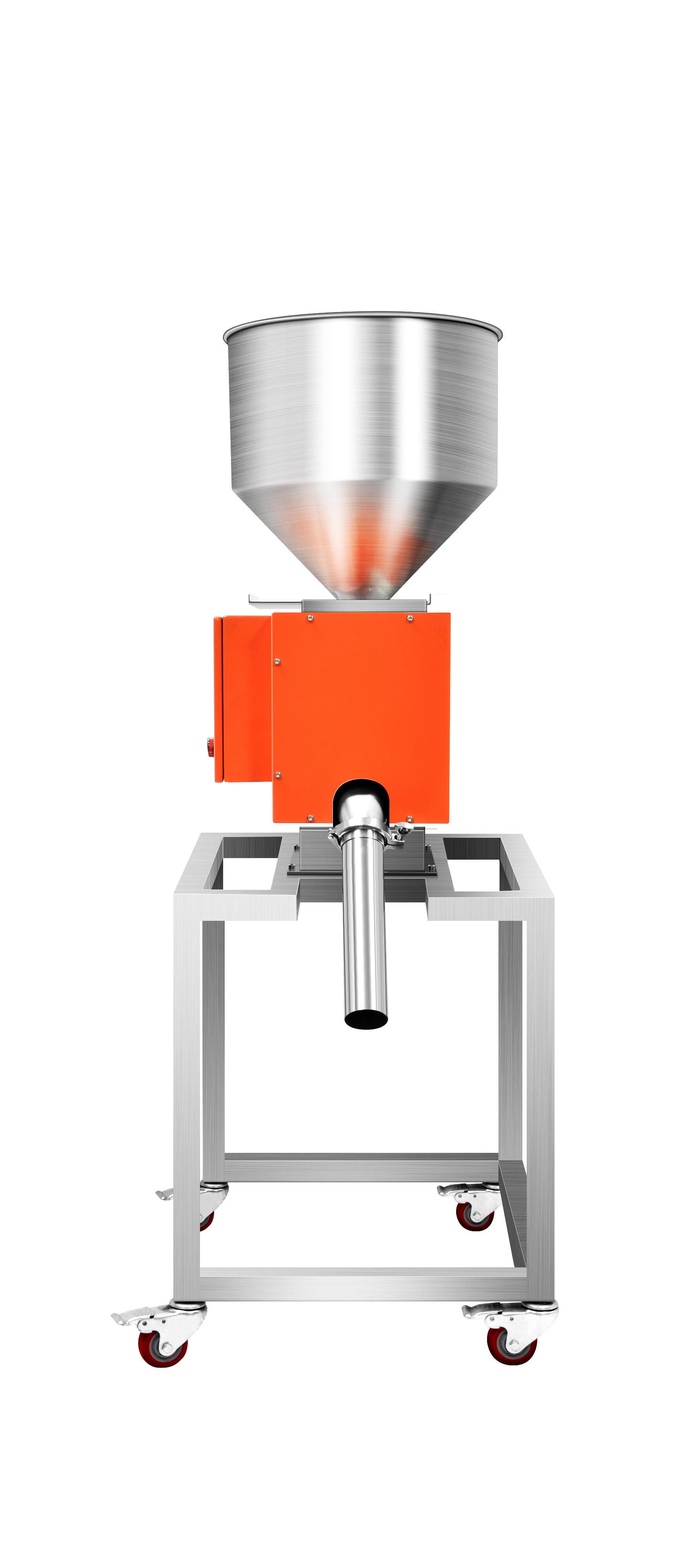

automatic free fall metal separator

The automatic free fall metal separator represents a cutting-edge solution in quality control and contamination prevention for bulk material processing. This sophisticated device operates by detecting and removing metallic contaminants from free-falling bulk materials through a combination of advanced detection technology and precision separation mechanisms. The system employs highly sensitive sensors that can identify ferrous, non-ferrous, and stainless steel particles with remarkable accuracy, even at high throughput rates. The separator's design incorporates a vertical inspection channel where materials flow freely, allowing for optimal detection conditions. When metal contamination is detected, a high-speed rejection mechanism activates instantly, diverting the contaminated portion while maintaining the integrity of the main product flow. The technology features automatic self-calibration and monitoring systems, ensuring consistent performance and reliability. Applications span across numerous industries, including food processing, pharmaceuticals, plastics, chemicals, and recycling. The separator's modular design allows for easy integration into existing production lines, while its user-friendly interface enables straightforward operation and maintenance. Advanced digital controls provide real-time monitoring and documentation capabilities, meeting modern industry requirements for traceability and quality assurance.