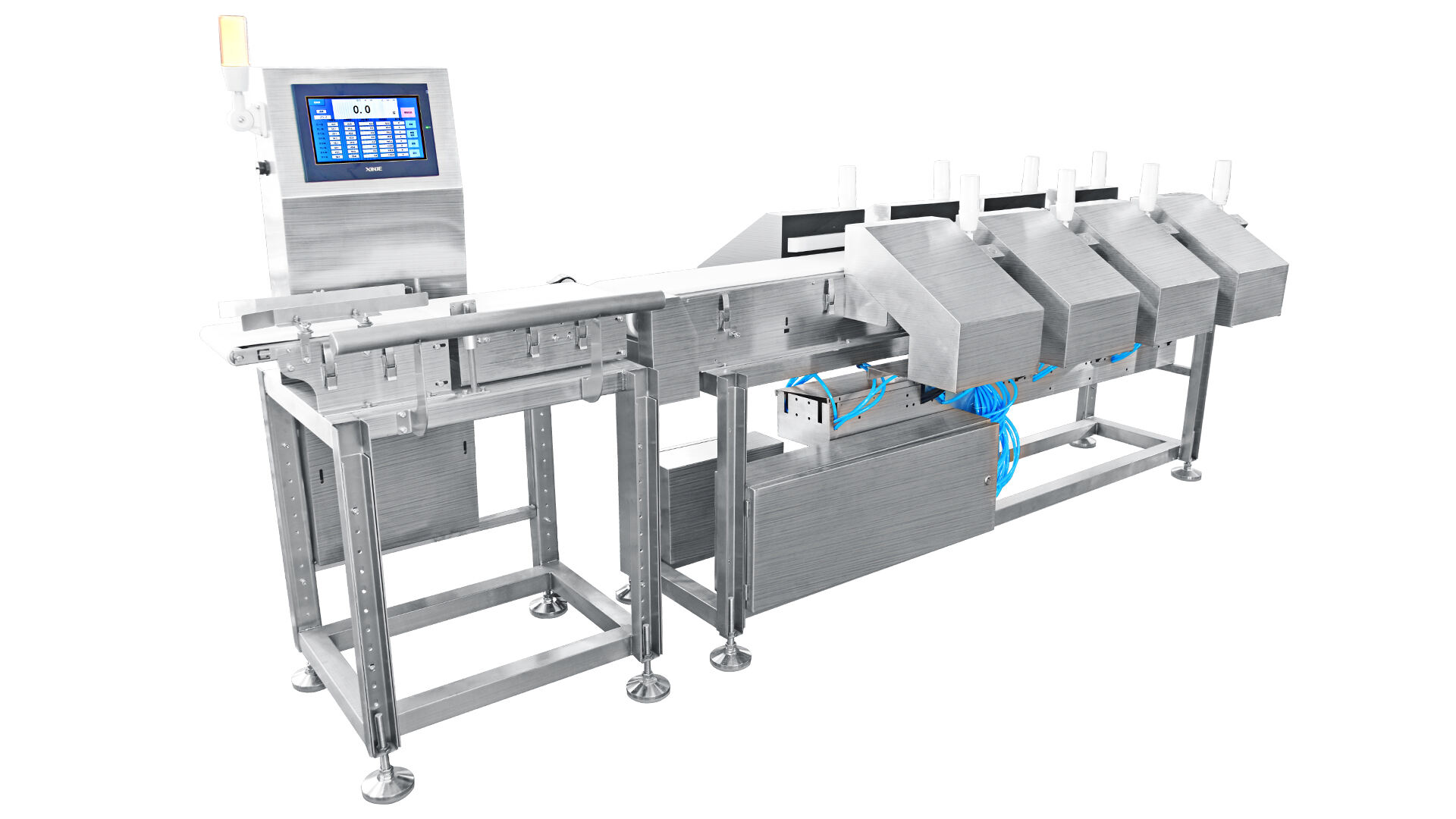

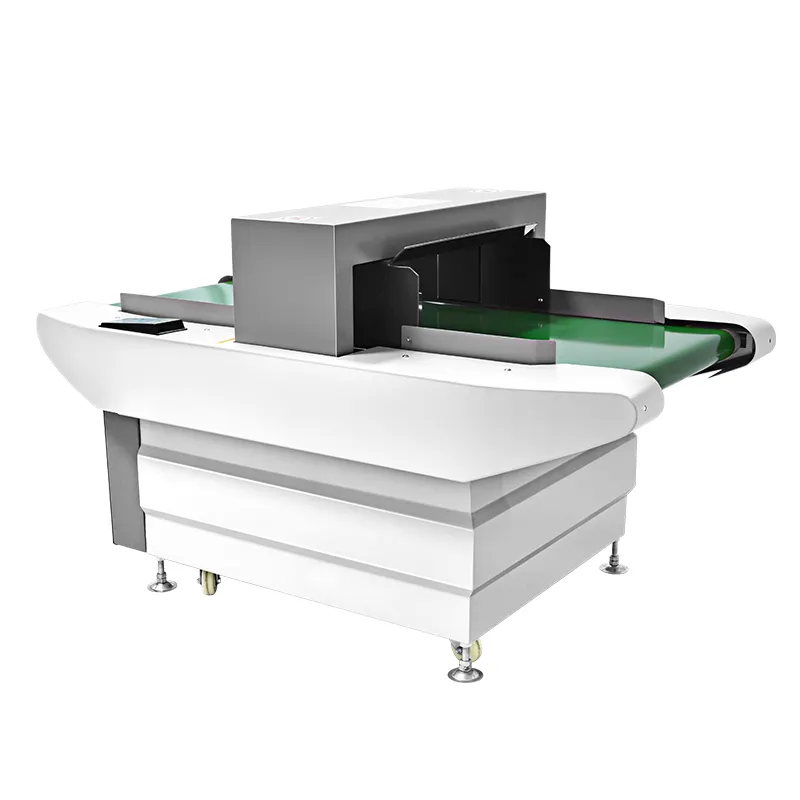

food metal detector price

Food metal detector prices vary significantly based on their technological capabilities, detection accuracy, and throughput capacity. These essential quality control devices typically range from $3,000 to $25,000, with advanced models featuring superior sensitivity and larger aperture sizes commanding higher prices. Modern food metal detectors incorporate sophisticated multi-frequency technology, enabling them to detect ferrous, non-ferrous, and stainless steel contaminants with exceptional precision. The price point often reflects additional features such as automatic product learning, data logging capabilities, and compliance with HACCP requirements. Entry-level models, while more affordable, still maintain reliable detection of common metal contaminants and are suitable for small to medium-scale operations. Mid-range units, priced between $8,000 and $15,000, often include enhanced sensitivity levels, user-friendly interfaces, and comprehensive reporting functions. Premium models incorporate advanced digital signal processing, remote monitoring capabilities, and integration with existing production lines, justifying their higher investment cost. When considering the price, factors such as aperture size, belt speed capacity, and IP rating for washdown protection significantly influence the final cost.