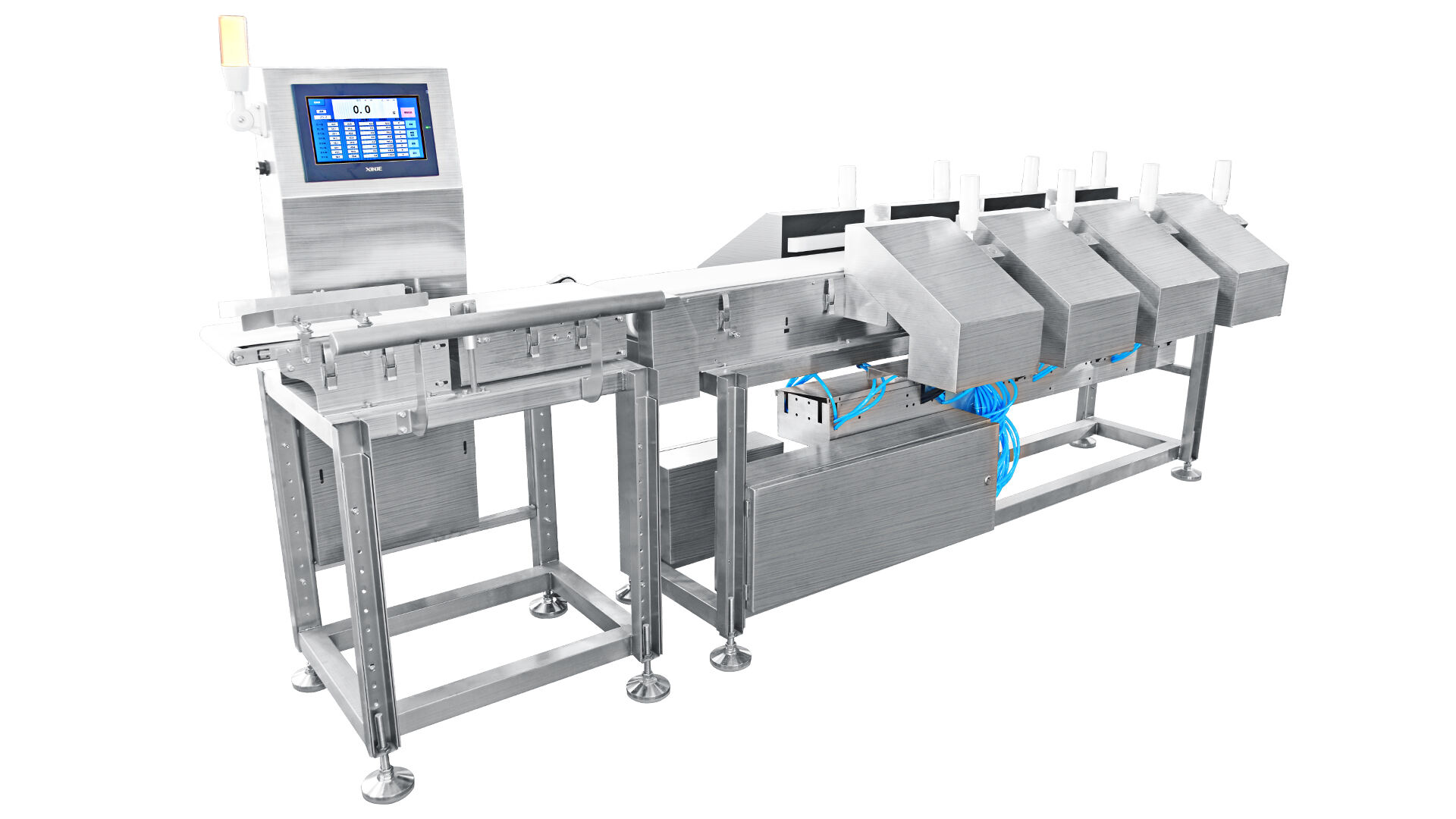

small metal separator machine

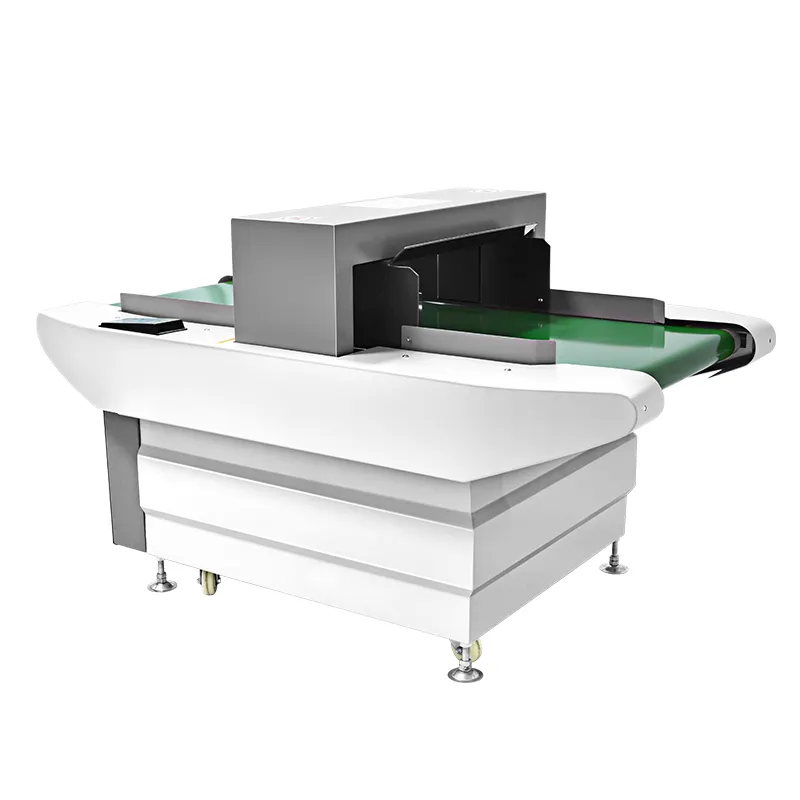

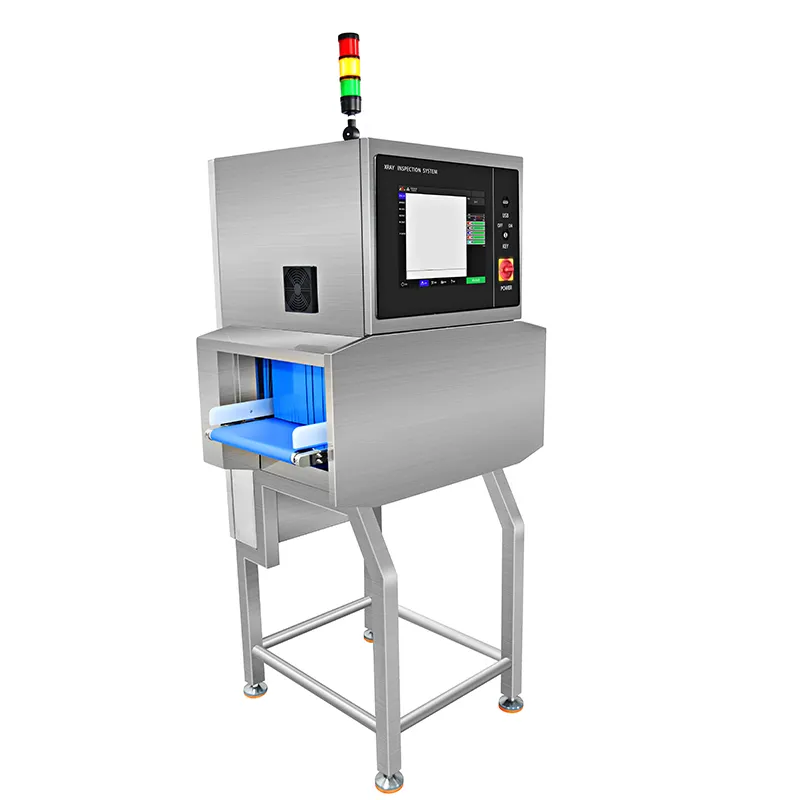

The small metal separator machine represents a cutting-edge solution in material processing and quality control. This compact yet powerful device efficiently detects and removes metallic contaminants from various product streams, ensuring product purity and equipment protection. Operating through advanced electromagnetic technology, the machine generates a precise detection field that identifies both ferrous and non-ferrous metals. When metal particles are detected, the system triggers a rapid-response rejection mechanism that automatically removes the contaminated material from the production line. The machine's sophisticated digital signal processing allows for exceptional sensitivity while minimizing false rejections. Its compact design makes it ideal for installations where space is limited, while its robust construction ensures reliable operation in demanding industrial environments. The system features user-friendly controls and adjustable sensitivity settings, allowing operators to fine-tune detection parameters based on specific product requirements. Applications span across multiple industries, including food processing, pharmaceuticals, plastics, chemicals, and recycling. The machine's ability to handle various product forms, from powders to granules, makes it versatile for different production needs. Regular calibration and maintenance are simplified through its accessible design and clear diagnostic indicators.