আপনার শিল্পের চাহিদা জানুন → পণ্যের প্যারামিটার নিশ্চিত করুন → কাস্টমাইজড সমাধান প্রদান করুন → উদ্ধৃতি দিন → বিনামূল্যে নমুনা পরীক্ষা প্রদান করুন

তুলোর মধ্যে সূঁচের টুকরো লুকিয়ে থাকে। ⚠️ নরমতা তাদের ছদ্মবেশ।

একটি চলমান প্রক্রিয়া: ♻️ ছাঁচের ক্ষয়ের ফলে ধাতব টুকরো তৈরি হয়।

উচ্চ-নির্ভুলতা সূঁচ সনাক্তকরণ যন্ত্র

ব্যবহার করে 3মিমি আয়না-সমাপ্তি স্টেইনলেস স্টিল । এর লৌহ ধাতু সনাক্তকরণ সংবেদনশীলতা হল ≥0.8mm , যার পরিবহনের গতি নিয়ন্ত্রণযোগ্য 25-30মি/মিনিট . সামগ্রীকরণ সমর্থিত .

হাই-স্পিড ধাতব সনাক্তকরণ যন্ত্র

Fe (ফেরাস) ধাতু ≥ 0.7মিমি , নন-ফে (নন-ফেরাস) ধাতু ≥ 1.2মিমি , 304 স্টেইনলেস স্টিল ≥ 1.5মিমি এটি এক ক্লিকে স্বয়ংক্রিয় সেটআপ সহ আসে, 100 সেট পণ্য প্যারামিটার সংরক্ষণের সুবিধা দেয় এবং অ্যালুমিনিয়াম ফয়েল প্যাকেজিংয়ের মধ্যেও ধাতু শনাক্ত করতে পারে।

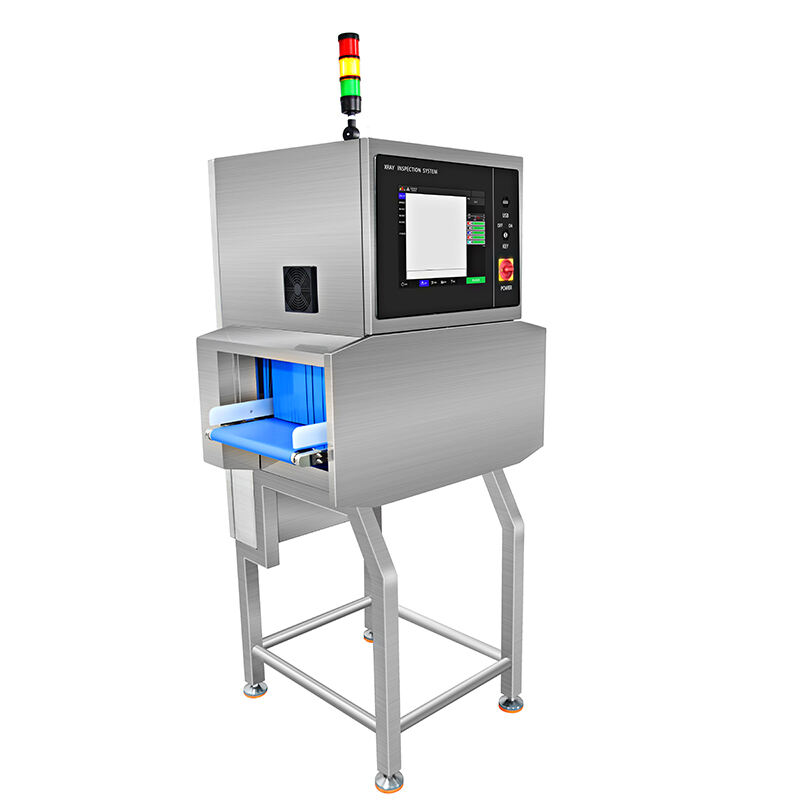

বিদেশী বস্তু এক্স-রে সনাক্তকরণ যন্ত্র

সনাক্তকরণের সংবেদনশীলতার মধ্যে রয়েছে স্টেইনলেস স্টিলের বল ≥ 0.3মিমি , স্টেইনলেস স্টিলের তার ≥ 0.2মিমি × 2মিমি , সিরামিক বল ≥ 0.7মিমি , এবং কাচের বলগুলি ≥ 1.0মিমি . এটি 15-ইঞ্চির ফুল-কালার টাচস্ক্রিন এবং স্বয়ং-শিক্ষণ ফাংশন দিয়ে সজ্জিত, স্বয়ংক্রিয় ইমেজিং সক্ষম করে .

হুইজাউ-এর একটি প্লাস্টিকের খেলনা কারখানা ছোট শিশুদের জন্য প্লাস্টিকের খেলনা উৎপাদনে বিশেষীকরণ করে। আগে এটি ধাতব বিদেশী বস্তু খুঁজে বার করতে হাতে-কলমে পরিদর্শনের উপর নির্ভর করত এবং সবসময় মনে করত যে "চোখে-চোখে + স্পর্শ" পদ্ধতি যথেষ্ট। ছাঁচের ক্ষয়ক্ষতির কারণে 0.9 মিমি লৌহ গুঁড়ো থাকার কারণে খেলনার একটি ব্যাচ ধরা পড়া পর্যন্ত এই অবস্থা চলতে থাকে। গ্রাহক এটি দৈব চিহ্নিতকরণের সময় সমস্যাটি ধরতে পারে, যার ফলে তারা শুধু পুরো ব্যাচ ফেরত দেয়নি বরং ভবিষ্যতের সহযোগিতা স্থগিত করে দেয়।