կերակրության կշիռների ստուգող

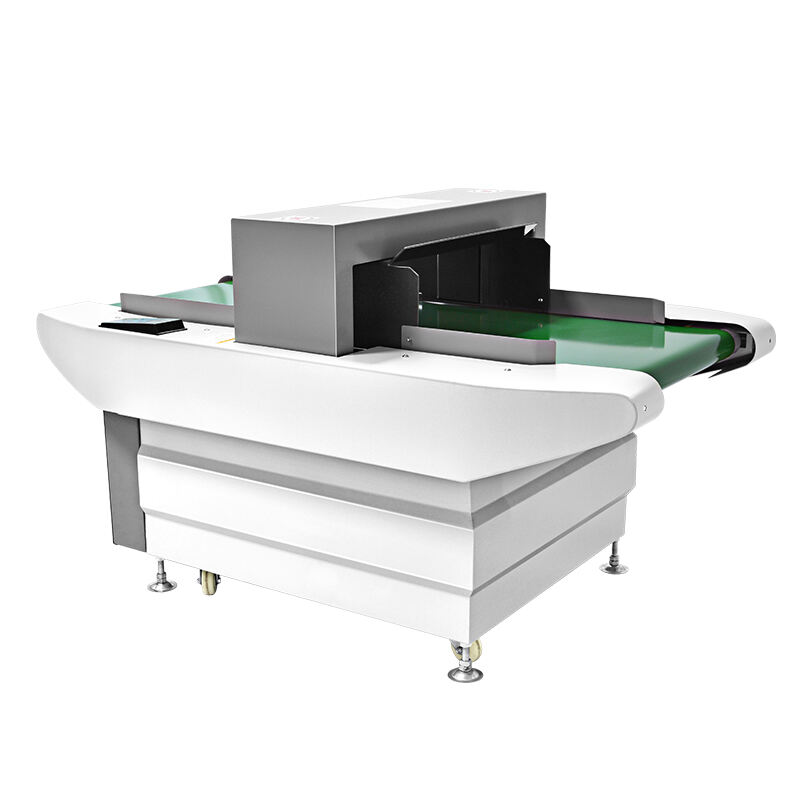

Սննդի ստուգման կշեռքը առաջադեմ որակի վերահսկման սարք է, որն նախատեսված է սննդի արտադրության գծերում ճշգրիտ քաշի չափումներ ապահովելու համար: Այս բարդ սարքավորումը միավորում է ճշգրիտ կշռման տեխնոլոգիան և բարձր արագությամբ մշակման հնարավորություններ՝ իրական ժամանակում ստուգելու արտադրանքի քաշի համապատասխանությունը: Կազմակերպված ժապավենի համակարգի միջոցով՝ ստուգման կշեռքը ավտոմատ կերպով կշռում է յուրաքանչյուր արտադրանք, երբ այն անցնում է դրա միջով, և համեմատում է չափումները նախօրոք որոշված պարամետրերի հետ: Համակարգը ստանձնում է առաջադեմ թվային մշակման միավորներ, որոնք կարող են մշակել րոպեում հարյուրավոր ապրանքներ՝ պահպանելով բացառիկ ճշգրտություն՝ մինչև գրամի մասերի չափով: Ժամանակակից սննդի ստուգման կշեռքները ներառում են խելացի տեխնոլոգիաներ՝ ներառյալ տակտիլ ինտերֆեյսներ, տվյալների մշակման հնարավորություններ և ցանցային կապ՝ հեռակա վերահսկման և կառավարման համար: Այս համակարգերը հագեցված են ավտոմատ մերժման մեխանիզմներով, որոնք անմիջապես հեռացնում են այն արտադրանքները, որոնք չեն համապատասխանում սահմանված քաշի սահմաններին՝ ապահովելով որակի վերահսկման ստանդարտների անընդհատ կատարումը: Տեխնոլոգիայի բազմակողմանիությունը հնարավորություն է տալիս այն օգտագործել տարբեր սննդամթերքների համար՝ սկսած թեթև սնունդներից մինչև ծանր փաթեթավորված ճաշեր, ինչը դարձնում է այն անփոխարինելի ժամանակակից սննդի մշակման կենտրոններում: Այս համակարգերի ինտեգրման հնարավորությունները թույլ են տալիս հարթ կապ ապահովել արտադրական գծի այլ բաղադրիչների հետ՝ ստեղծելով համապարփակ որակի վերահսկման լուծում, որն ավելի արդյունավետ է դարձնում ընդհանուր գործողությունները:

![Արկղային գործիքների ].' Համար պատրաստական համալիրի ստուգումների համար](https://shopcdnpro.grainajz.com/category/5221/1574/6ae53ea26af7233f479dcf54bce02766/image.png)