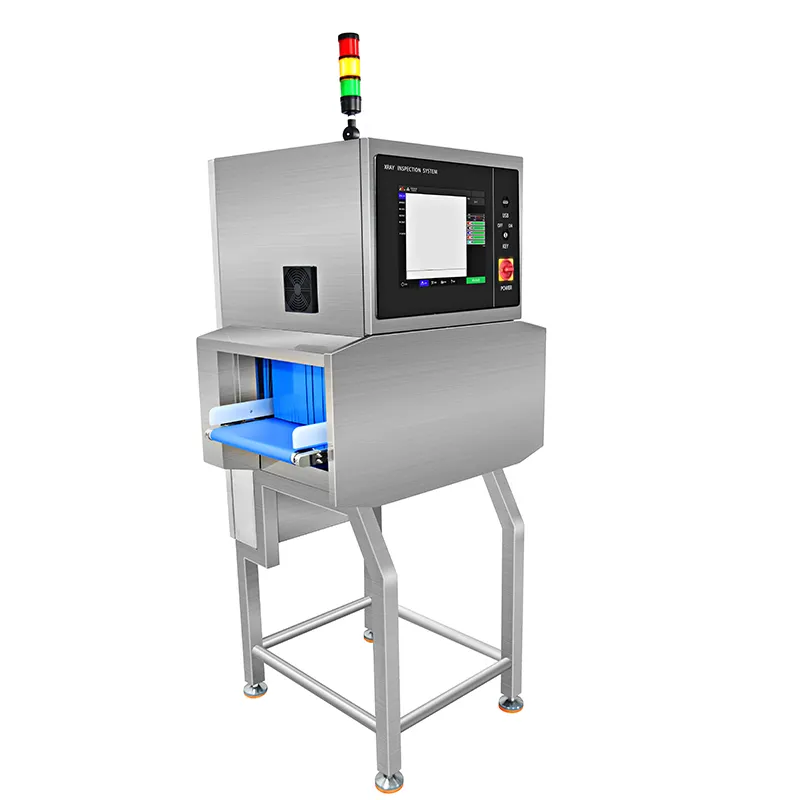

machina radiographica in fabrica cibaria

Machinae radiographicae in fabricis ciborum sunt systemata inspectiva docta quae tutitatem et qualitatem productorum in manufactoriis cibaria confirmare parata sunt. Haec instrumenta provecta technologiam radiographicam altissimae praecisionis utuntur ut contaminantes et defectus in cibariis durante processo productionis detegant. Machina varia materia peregrina, inter quae fragmenta metalli, particulas vitri, plasticum densum, lapides et ossa calcificata, etiam ubi producta implicata sunt, agnoscere potest. Per systema catenae transporteris functa, res per fasciculum radiographiae transeunt dum software doctum imagines tempore vero analysat, producta contaminata automatice repudiando. Haec technologia facultates inspectionis amplas offert, inter quas mensurationem massae, verificationem plenitudinis recipientis, et examina integritatis producti. Machinae modernae radiographicae in fabricis ciborum interfacies amicabiles usu, parametros inspectionis multiplices habent et magnitudines productorum varias ac genera implicationis tractare possunt. Haec systemata cum normis internationalibus et regulis de tutela ciborum consentiunt, reportationes minutissimas de inspectione et annotationem datorum pro ratione certificandi qualitatis praebendo. Machinae secundum considerationes hygienicas factae sunt, constructione ex stanno ferroso et superficiebus purgandis facile, quae eos ad ambientes processiones cibariorum idoneos reddunt.