fornices inspectionis ciborum radiographici

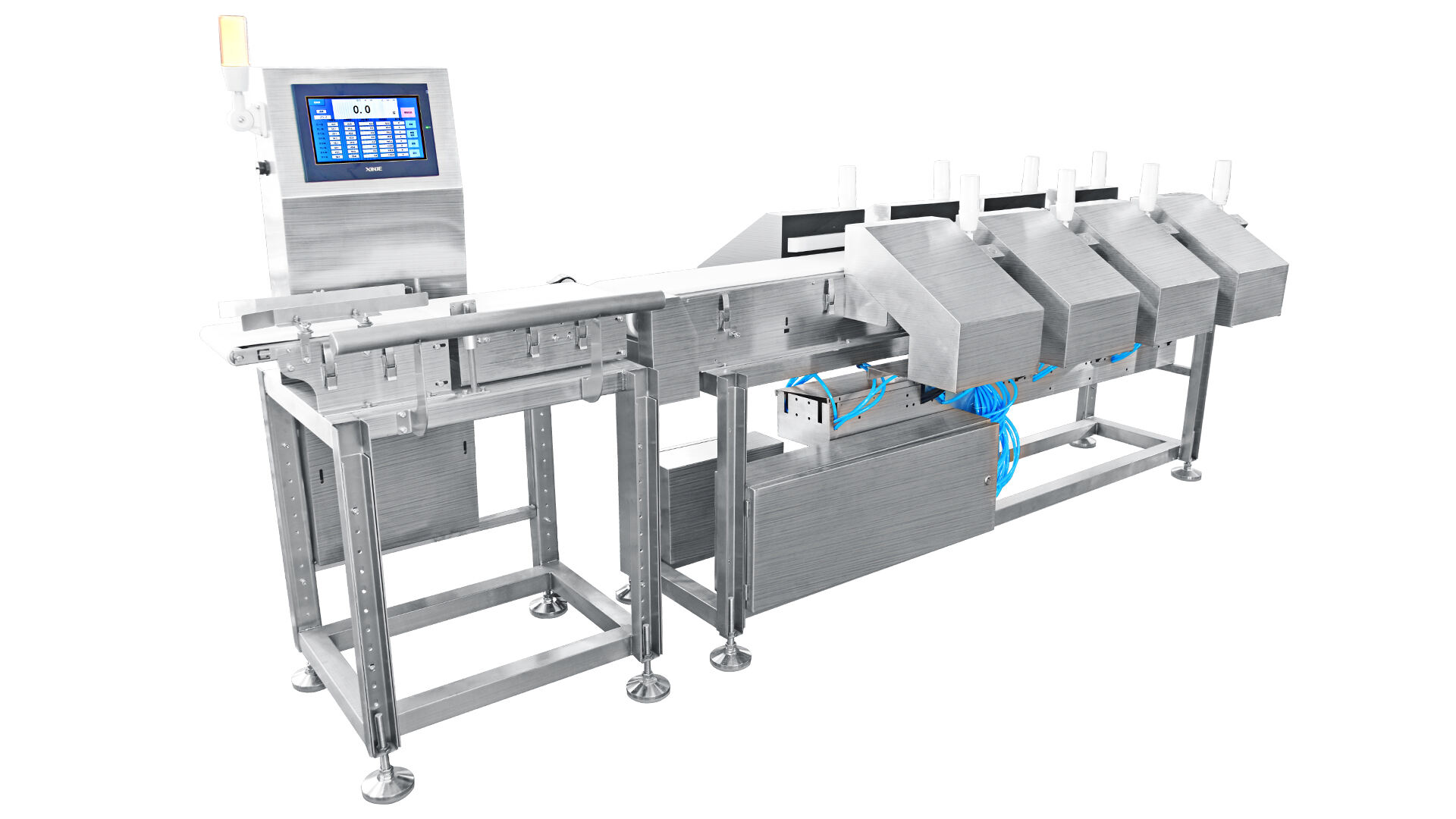

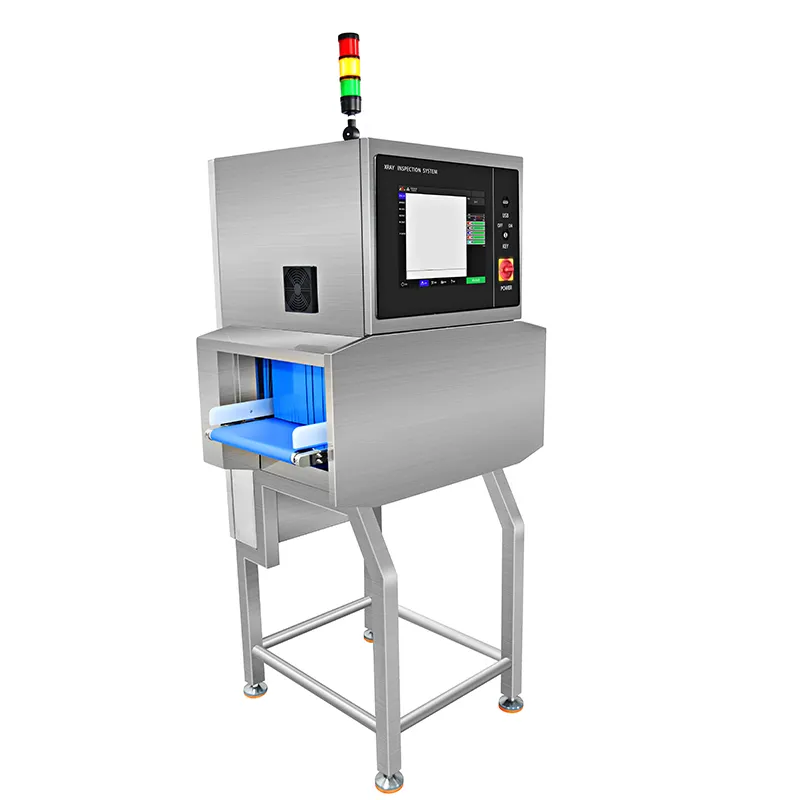

Fornix machinarum inspicientium cibos per radiographiam in prima fronte technologiae tutelae cibi stat, solutiones praeclaras pro controllo qualitatis in productione ciborum praebens. Hi fornices systemata inspectionis completa offerunt quae technologiam radiographiae progressam utuntur ad varia contaminamenta et vitia in cibis detegenda. Machinae materia peregrina ut ferrum, vitrum, saxum, os, et plasticum agnoscere possunt, simulque functiones qualitatis sicut mensuram massae, verificationem plenitudinis, et aestimationem integritatis cibi perficiunt. Systemata hodierna inspectionis per radiographiam capacitates imaginum altioris resolutionis habent, algorithmos software sophisticiatos ad analysin tempore reali, et interfaces usori amicas quae imperium exactum et observationem permittunt. Hi fornices sollicitudo plena praebent, inclusis installatione, doctrina, servitio manutentionis, et auxilio technico continuo. Systemata ita sunt parata ut sine difficultate in lineas productivas iam existentes integrari possint, operationibus minime interruptis, simulque velocitates excelsas pervectionis servant. Fornices machinas suas secundum normas regulasque internationales tutelae cibi esse conformes efficiunt, inter quas HACCP et FSMA continentur. Optiones etiam adaptationis specialis offerunt ad necessitates industriales peculiares satisfaciendum, sive pro cibis coniectis, mercibus rudi, sive cenis paratis ad edendum. Technologia a fornices usurpata evolvitur, artificialem intelligentiam et discendi machinalem capabilitates includens, ut accuratior detectio fiant et falsae rejectiones minuantur.