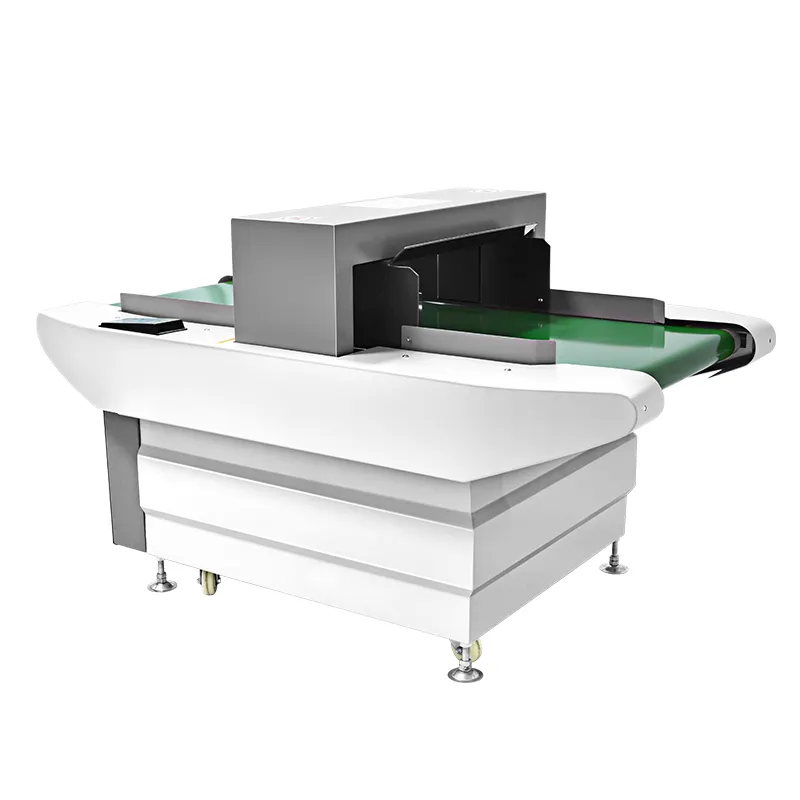

compacte weeginspectieband

De compacte weeginspectieband vormt een geavanceerde oplossing voor kwaliteitscontrole en productverificatieprocessen. Dit geavanceerde systeem combineert precisieweegtechnologie met efficiënte transportbandoperaties in een ruimtebesparend ontwerp. Met gebruik van geavanceerde loadcell-technologie meet het systeem nauwkeurig het gewicht van producten terwijl de productiestroom ononderbroken blijft. Het systeem is uitgerust met hoogwaardige gewichtssensoren die minimale afwijkingen kunnen detecteren, zodat gegarandeerd wordt dat producten exact aan de specificaties voldoen. Dankzij het modulaire ontwerp kan het probleemloos worden geïntegreerd in bestaande productielijnen, terwijl het compacte formaat het ideaal maakt voor bedrijven met beperkte ruimte. De transportsysteem verwerkt verschillende productafmetingen en -vormen, met instelbare geleidingsrails en band snelheden om tegemoet te komen aan uiteenlopende productie-eisen. De constructie van roestvrij staal garandeert duurzaamheid en conformiteit met voedselveiligheidsnormen, waardoor het bij uitstek geschikt is voor de levensmiddelen-, farmaceutische- en verpakkingsindustrie. Het systeem beschikt over geavanceerde dataverzamelmogelijkheden, waardoor real-time bewaking en rapportage van gewichtsstatistieken mogelijk is. Deze functie stelt in staat om direct producten buiten specificatie te identificeren en levert waardevolle productie-analysegegevens op. De intuïtieve bedieningsinterface vereenvoudigt bediening en onderhoud, terwijl geautomatiseerde afkeurmechanismen ervoor zorgen dat niet-conforme producten efficiënt van de productielijn worden verwijderd.