fabrikant van voedselmetaaldetectoren

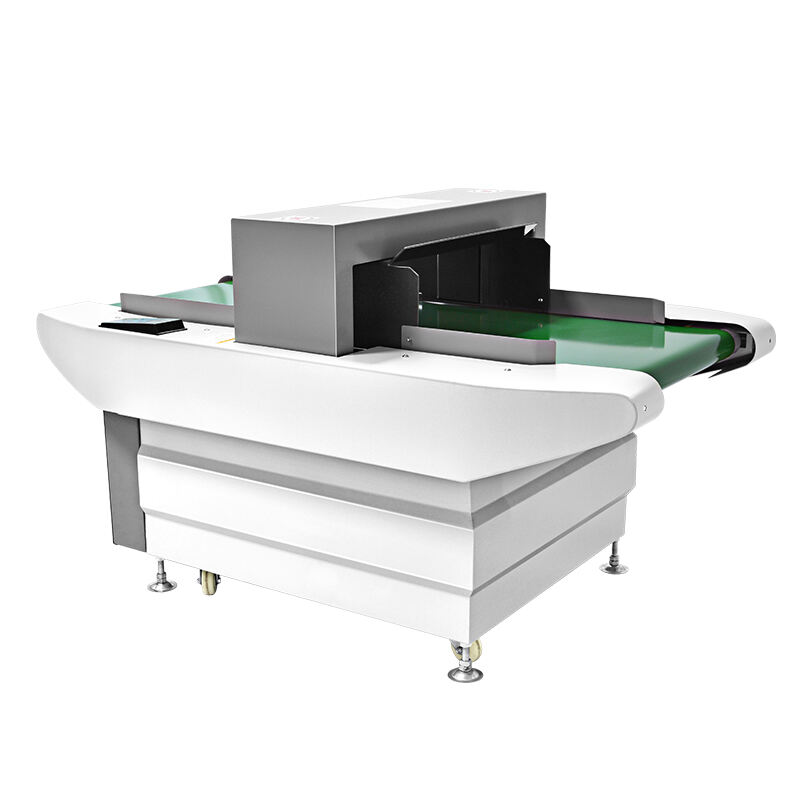

Een fabrikant van voedselmetaaldetectoren staat aan de voorhoede van voedselveiligheidstechnologie en is gespecialiseerd in het ontwerpen en produceren van geavanceerde detectiesystemen die consumenten beschermen en de reputatie van merken waarborgen. Deze fabrikanten ontwikkelen geavanceerde apparatuur die gebruikmaakt van multifrequentietechnologie en hooggevoelige sensoren om metalen verontreinigingen uit voedingsmiddelen te detecteren en verwijderen tijdens het productieproces. Hun systemen zijn ontworpen om ferro-, non-ferro- en roestvrijstalen deeltjes te identificeren, zelfs in uitdagende producten met een hoog vochtgehalte of variabele dichtheid. Moderne fabrikanten van voedselmetaaldetectoren integreren slimme functies zoals automatische kalibratie, dataloggingmogelijkheden en afstandsmonitoringssystemen om consistente prestaties en naleving van voedselveiligheidsvoorschriften te garanderen. Zij bieden op maat gemaakte oplossingen voor diverse toepassingen in de voedingsindustrie, van inspectie van grondstoffen tot controle van eindverpakkingen, met transportsysteemen die zijn ontworpen om producten van verschillende maten en vormen te verwerken. Deze fabrikanten bieden ook uitgebreide ondersteuningsdiensten, waaronder installatie, training, onderhoud en certificering, om optimale systeemprestaties en naleving van voorschriften te waarborgen. Hun toewijding aan innovatie zorgt voor voortdurende verbeteringen in detectiegevoeligheid, vermindering van valse afkeuringen en verbetering van gebruiksvriendelijke interfaces.