leveranciers van hoogwaardige controleweegsystemen

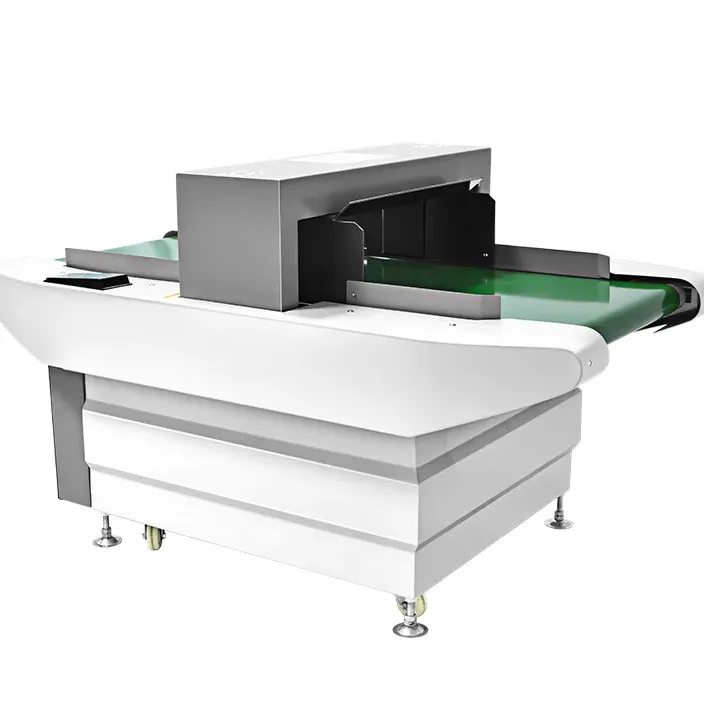

Leveranciers van hoogwaardige controleweegschalen zijn marktleiders op het gebied van geavanceerde weegoplossingen voor productie- en verpakkingsprocessen. Deze leveranciers bieden modernste controleweegsystemen die precisie-mechanica combineren met geavanceerde elektronische regelingen om in real-time nauwkeurige gewichtsverificatie van producten te garanderen. Hun systemen beschikken doorgaans over hoogresolutie loadcells, geavanceerde digitale signaalverwerking en intuïtieve gebruikersinterfaces die nauwkeurige gewichtsmetingen bij hoge snelheden mogelijk maken. Deze leveranciers leveren apparatuur die geschikt is voor verschillende productafmetingen en -gewichten, met een nauwkeurigheid die vaak tot 0,01 gram reikt. Moderne controleweegschalen van deze leveranciers zijn uitgerust met functies zoals automatische kalibratie, multi-zone gewichtscontrole en geavanceerde afwijzingsmechanismen voor niet-conforme producten. De systemen zijn hygiënisch ontworpen en voldoen vaak aan IP65- of IP69K-normen voor afspoelomgevingen. Veel leveranciers bieden ook geïntegreerde datamanagementoplossingen waarmee uitgebreide productiemonitoring, statistische analyse en conformiteitsrapportage mogelijk zijn. Hun apparatuur wordt toegepast in tal van industrieën, waaronder voedingsmiddelen, dranken, farmaceutische producten, cosmetica en chemische processen, waar gewichtsnauwkeurigheid cruciaal is voor kwaliteitscontrole en naleving van voorschriften.