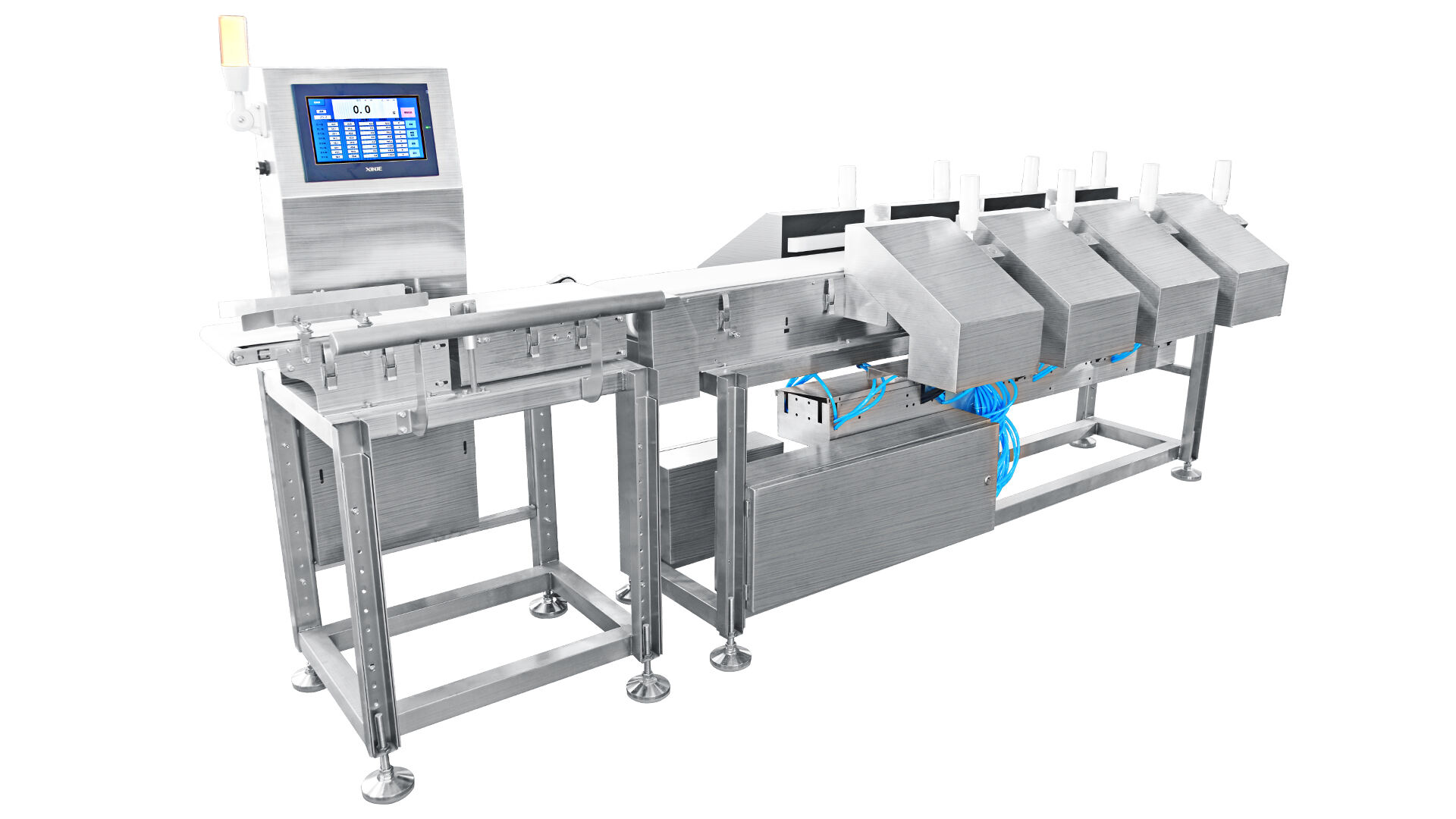

hoge snelheid kunststof-metaalscheider

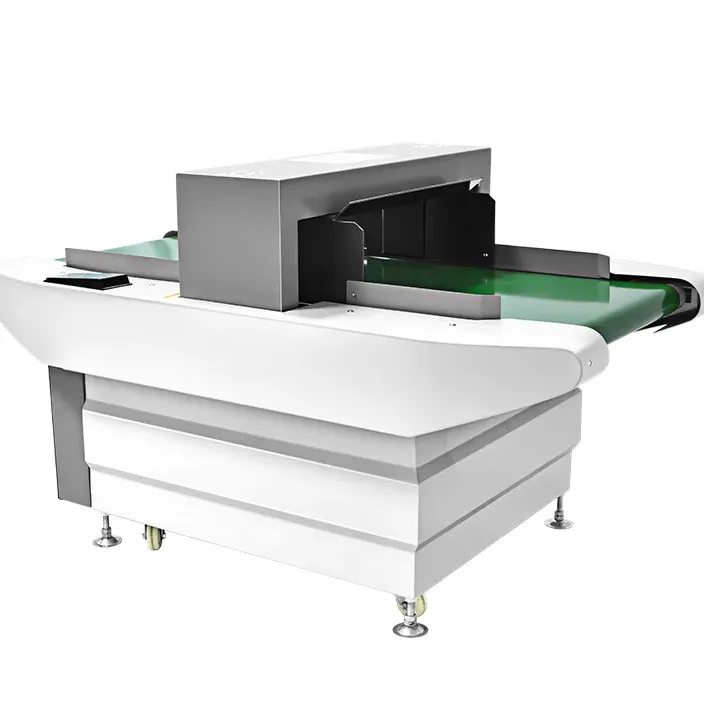

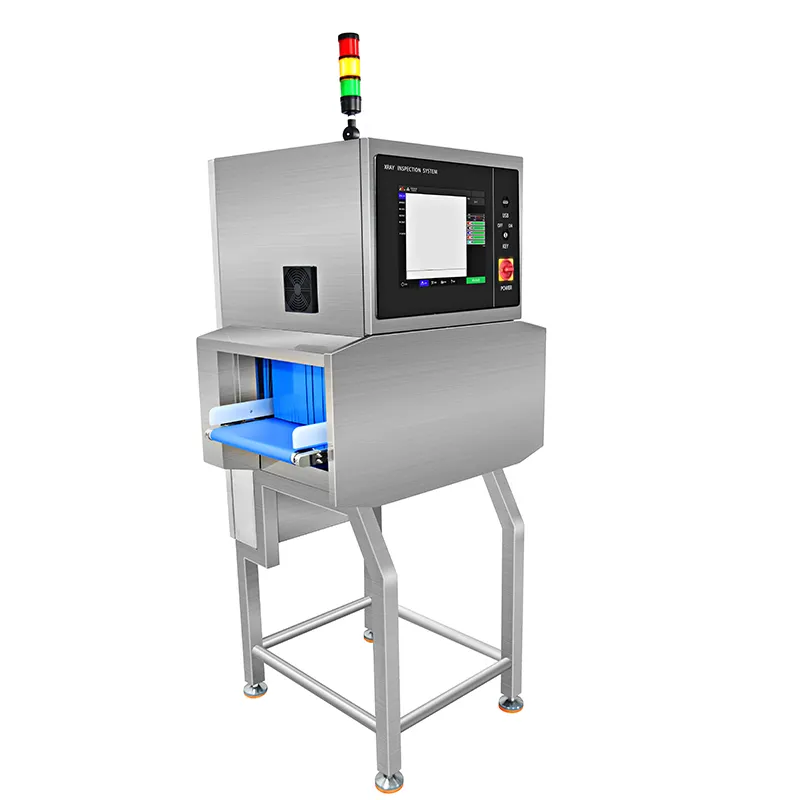

De high-speed kunststof-metaalscheider is een innovatieve oplossing in de recycling- en materiaalverwerkende industrie, ontworpen om metaalverontreinigingen efficiënt te scheiden van kunststofmaterialen bij hoge doorvoersnelheden. Dit geavanceerde systeem maakt gebruik van krachtige elektromagnetische velden en nauwkeurige detectietechnologie om zowel ferro- als non-ferrometalen uit kunststofstromen te identificeren en te verwijderen. Met een capaciteit van tot wel 3000 kg per uur gebruikt de scheider geavanceerde sensoren die metalen deeltjes kunnen detecteren van slechts 0,3 mm in doorsnede. Het automatische afwijzingsmechanisme zorgt voor ononderbroken bedrijf, terwijl de productkwaliteit wordt gehandhaafd en apparatuur stroomafwaarts wordt beschermd. Het systeem beschikt over een intuïtieve bedieningsinterface waarmee operators de gevoeligheidsinstellingen kunnen aanpassen en de prestaties in real-time kunnen monitoren. De scheider is bijzonder waardevol in kunststofrecyclinginstallaties, productiefaciliteiten en voedselverpakkingsindustrieën waar materiaalzuiverheid van cruciaal belang is. De robuuste constructie en afgedichte componenten garanderen betrouwbare werking in veeleisende industriële omgevingen met minimale onderhoudsbehoeften. Het systeem beschikt over zelfdiagnosemogelijkheden die de operators waarschuwen voor mogelijke problemen voordat deze de productie beïnvloeden, wat de uptime en operationele efficiëntie maximaliseert.