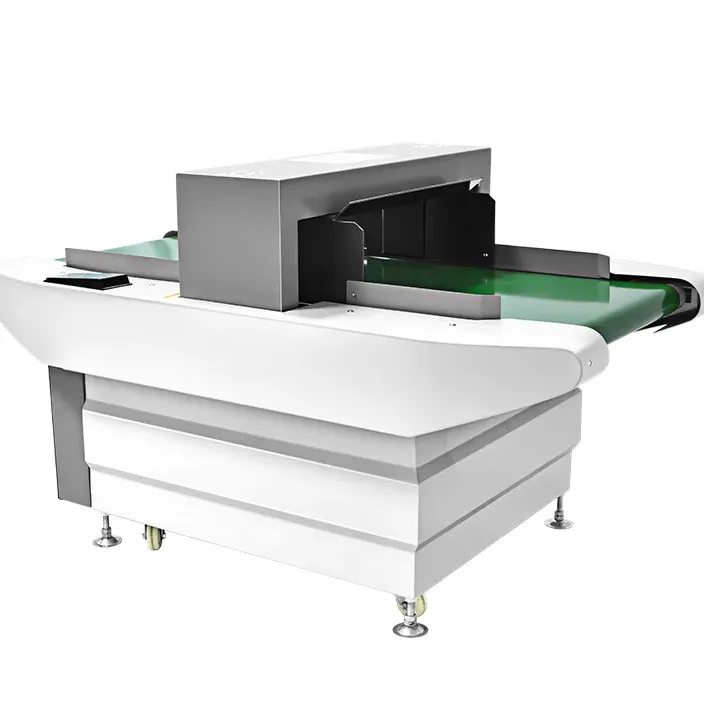

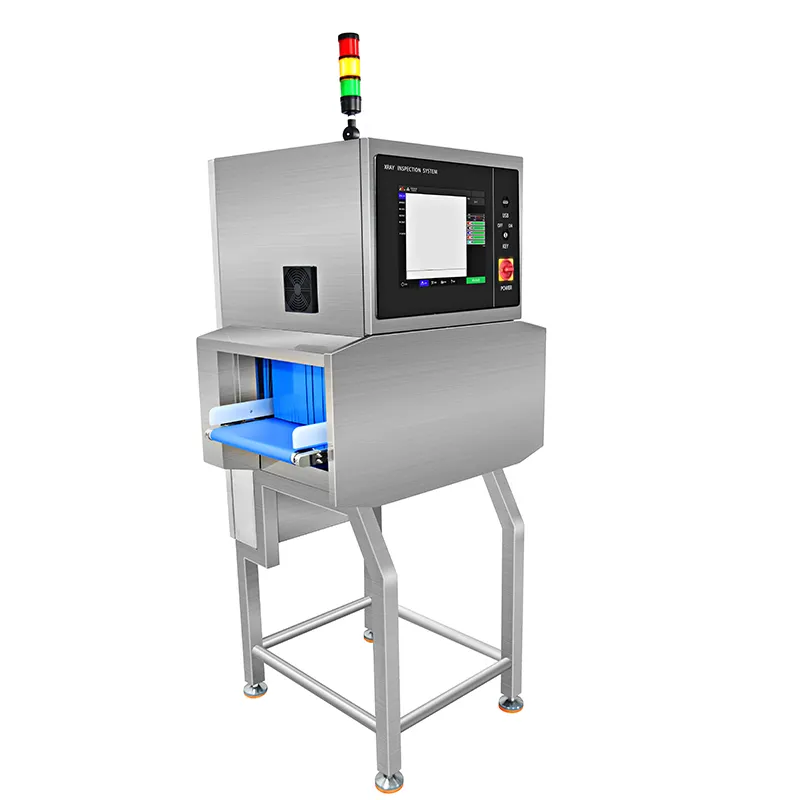

vlees röntgenmachine fabrikant

Een fabrikant van röntgenmachines voor vlees specialiseert zich in de productie van geavanceerde inspectiesystemen die zijn ontworpen om voedselveiligheid en kwaliteitscontrole in vleesverwerkende bedrijven te waarborgen. Deze geavanceerde apparaten maken gebruik van modern röntgentechnologie om mogelijke verontreinigingen op te sporen, waaronder metalen fragmenten, beenderdeeltjes, glas splinters en andere vreemde materialen die de productveiligheid kunnen compromitteren. De machines zijn uitgerust met hoogwaardige beeldsensoren en krachtige softwarealgoritmen om vleesproducten in real-time te analyseren, zodat een grondige inspectie wordt gewaarborgd zonder de productiestroom te verstoren. Moderne röntgensystemen voor vlees beschikken over gebruiksvriendelijke interfaces, geautomatiseerde afkeurmechanismen en uitgebreide dataloggingmogelijkheden voor kwaliteitsborging en naleving van voorschriften. Deze fabrikanten bieden doorgaans verschillende modellen aan om tegemoet te komen aan uiteenlopende productieomvang en specifieke inspectiebehoeften, van instapmodellen voor kleine verwerkers tot hoge-snelheids, meervoudige baaninstallaties voor grootschalige operaties. De apparatuur is ontworpen om te voldoen aan strenge voedselveiligheidsregelgeving en sectornormen, terwijl tegelijkertijd de optimale productie-efficiëntie wordt behouden. Fabrikanten bieden ook essentiële diensten zoals installatie, training, onderhoud en technische ondersteuning om maximale prestaties en levensduur van het systeem te garanderen.