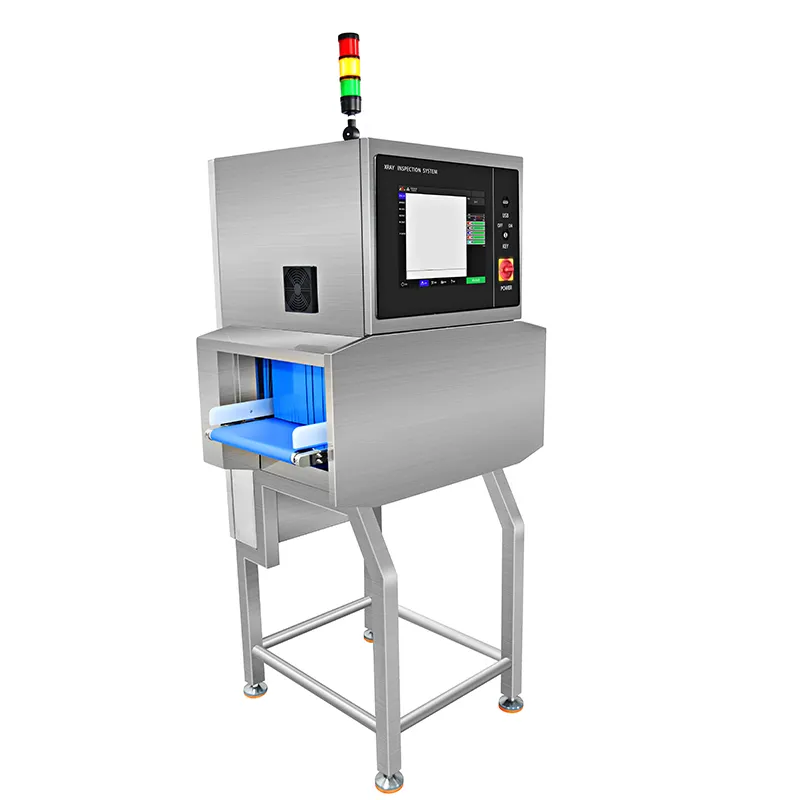

op maat gemaakte metaaldetector voor voedsel

De op maat gemaakte metaaldetector voor voedsel vormt een geavanceerde oplossing op het gebied van voedselveiligheid en kwaliteitscontrole. Dit geavanceerde detectiesysteem is specifiek ontworpen om metalen verontreinigingen in diverse voedselfproducten te identificeren en te elimineren tijdens het productieproces. Het systeem maakt gebruik van geavanceerde elektromagnetische technologie om ferro, non-ferro en roestvrijstalen deeltjes met uitzonderlijke precisie op te sporen, waardoor de hoogste normen voor voedselveiligheid worden gewaarborgd. De detector beschikt over aanpasbare gevoeligheidsinstellingen die kunnen worden afgesteld op verschillende producttypes en verpakkingsmaterialen. Het robuuste ontwerp omvat een gebruiksvriendelijke interface met realtime bewakingsmogelijkheden, zodat operators gedurende de hele productie consistent kwaliteitscontrole kunnen handhaven. Het systeem is uitgerust met automatische registratie- en rapportagefuncties, waardoor een uitgebreide documentatie van inspectieresultaten mogelijk is en naleving van voedselveiligheidsregelgeving wordt ondersteund. Dankzij de constructie met IP69K-classificatie weerstaat de detector strenge reinigingsprocedures en functioneert hij betrouwbaar in uitdagende voedselverwerkende omgevingen. Het modulaire ontwerp vergemakkelijkt eenvoudige integratie in bestaande productielijnen, terwijl de hoge verwerkingssnelheid efficiënte werking garandeert zonder afbreuk te doen aan de productiedoorvoer.