lajme për shpërndarjen e peshës

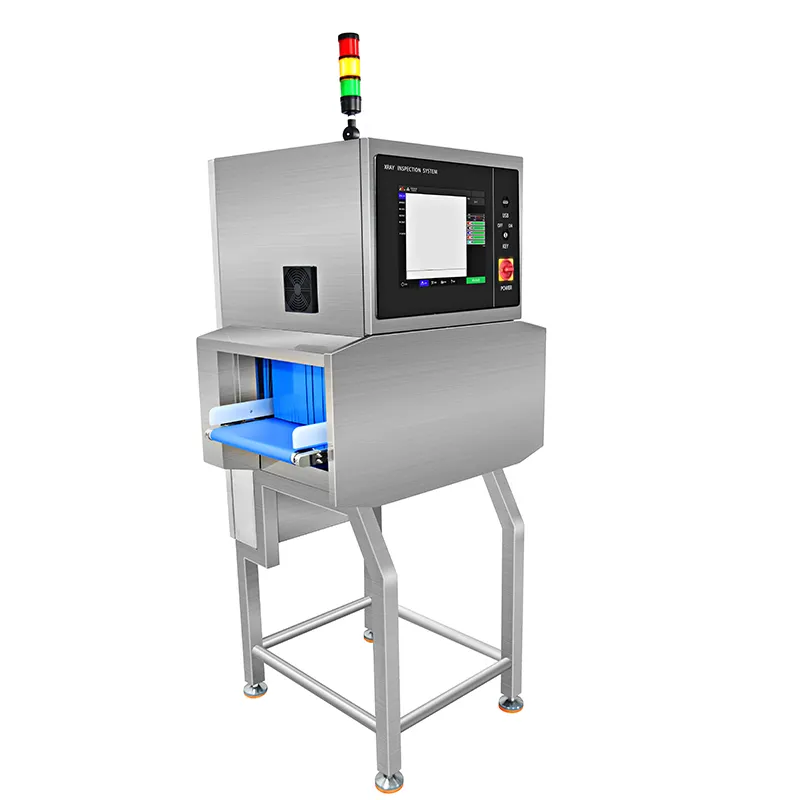

Një pajisje peshimi për shitje paraqet një zgjidhje të thellë në kontrollin e cilësisë dhe sistemet e verifikimit të peshës. Kjo pajisje e avancuar peshimi funksionon përmes një kombinimi sofistikuar të qelizave të saktësisë, sistemeve me shpejtësi të lartë transporti dhe mundësive inteligjente të përpunimit. Sistemi peshon efikas produktet në lëvizje, duke siguruar matje të sakta gjatë ruajtjes së shpejtësisë së linjës së prodhimit. Duke ofruar kontroll digital të fundit të teknologjisë dhe një ndërfaqe përdoruesi intuitive, pajisja lejon operatorëve të vendosin lehtë parametrat e peshës, të monitorojnë performancën dhe të gjenerojnë raporte të hollësishme. Makina zbulon dhe hedh automatikisht produktet që bien jashtë specifikimeve të paracaktuara të peshës, duke mbajtur standarde të qëndrueshme cilësie. Me modele të ndryshme të disponueshme, të përshtatshme për madhësi të ndryshme produkte dhe gamë peshash, këto sisteme mund të përpunojnë artikuj nga disa gram deri në disa kilogramë. Pajisja integrohet ngushtë me linjat ekzistuese të prodhimit dhe mund të personalizohet me veçori shtesë si aftësi detektimi metalik, sisteme regjistrimi të dhënash dhe mundësi monitorimi nga distanca. E ndërtuar me konstruksion prej çeliku të pangur të fortë, këto makina janë projektuar për jetëgjatësi dhe performancë të besueshme në mjedise industriale të kërkesësh të larta.