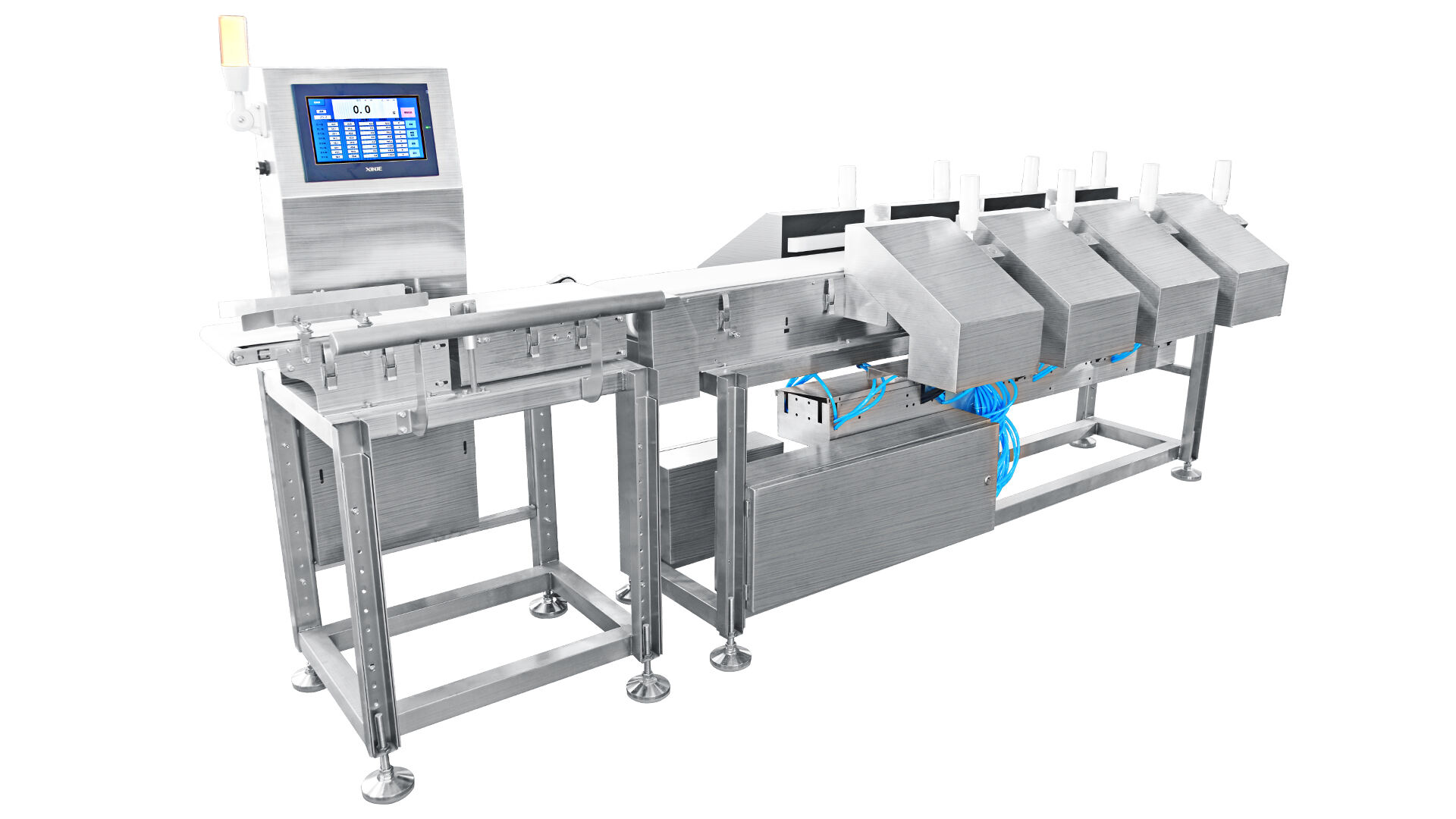

automatic check weigher

The automatic check weigher represents a crucial advancement in quality control and packaging automation. This sophisticated weighing system continuously monitors and verifies product weights in real-time during the production process, ensuring consistency and compliance with regulatory standards. Operating through a combination of precision load cells and advanced software algorithms, the system efficiently processes items on a conveyor belt, measuring their weight with exceptional accuracy. The technology incorporates high-speed weighing capabilities that can handle various product sizes and weights, making it suitable for diverse industries including food and beverage, pharmaceuticals, and consumer goods manufacturing. The system automatically segregates products that fall outside predetermined weight parameters, maintaining quality standards while minimizing waste. Modern automatic check weighers feature user-friendly interfaces that allow operators to easily adjust settings, monitor performance metrics, and generate comprehensive reports for quality assurance documentation. These systems can be seamlessly integrated into existing production lines and often include features such as data logging, statistical analysis, and remote monitoring capabilities, enabling businesses to optimize their production processes and maintain consistent product quality.