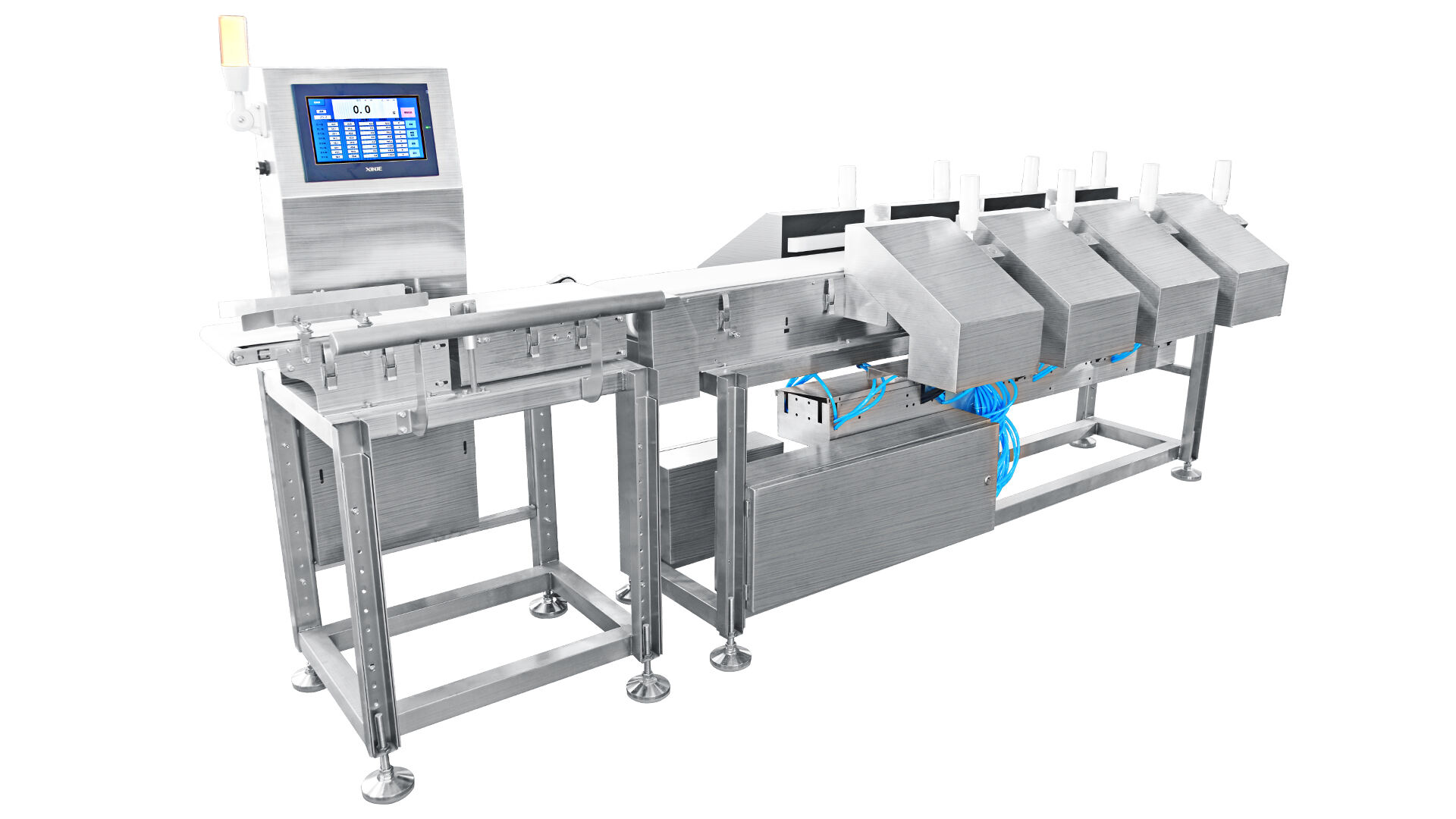

automatische check weigher

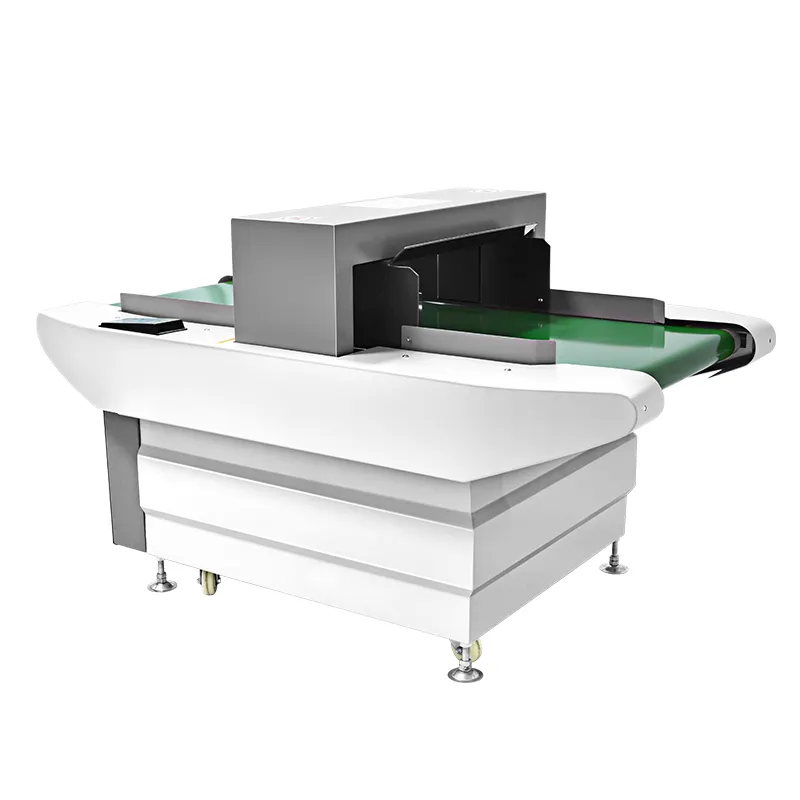

De automatische controleweegschaal vormt een cruciale vooruitgang in kwaliteitscontrole en verpakkingsautomatisering. Dit geavanceerde weegsysteem houdt tijdens het productieproces continu de productgewichten in realtime in de gaten en verifieert deze, waardoor consistentie en naleving van wettelijke normen worden gewaarborgd. Het systeem werkt met behulp van precisielastcellen en geavanceerde software-algoritmen, en verwerkt efficiënt producten op een transportband door hun gewicht met uitzonderlijke nauwkeurigheid te meten. De technologie beschikt over snelle weegmogelijkheden die verschillende productafmetingen en -gewichten aankunnen, waardoor het geschikt is voor diverse industrieën zoals voedingsmiddelen en dranken, farmaceutica en de fabricage van consumentengoederen. Het systeem sorteert automatisch producten uit die buiten vooraf bepaalde gewichtstoleranties vallen, waarbij de kwaliteitsnormen worden gehandhaafd en verspilling wordt geminimaliseerd. Moderne automatische controleweegschalen zijn uitgerust met gebruiksvriendelijke interfaces waarmee operators eenvoudig instellingen kunnen aanpassen, prestatiegegevens kunnen bewaken en uitgebreide rapportages kunnen genereren voor kwaliteitsborging. Deze systemen kunnen naadloos worden geïntegreerd in bestaande productielijnen en beschikken vaak over functies zoals datalogging, statistische analyse en mogelijkheden tot afstandsmonitoring, zodat bedrijven hun productieprocessen kunnen optimaliseren en een constante productkwaliteit kunnen handhaven.