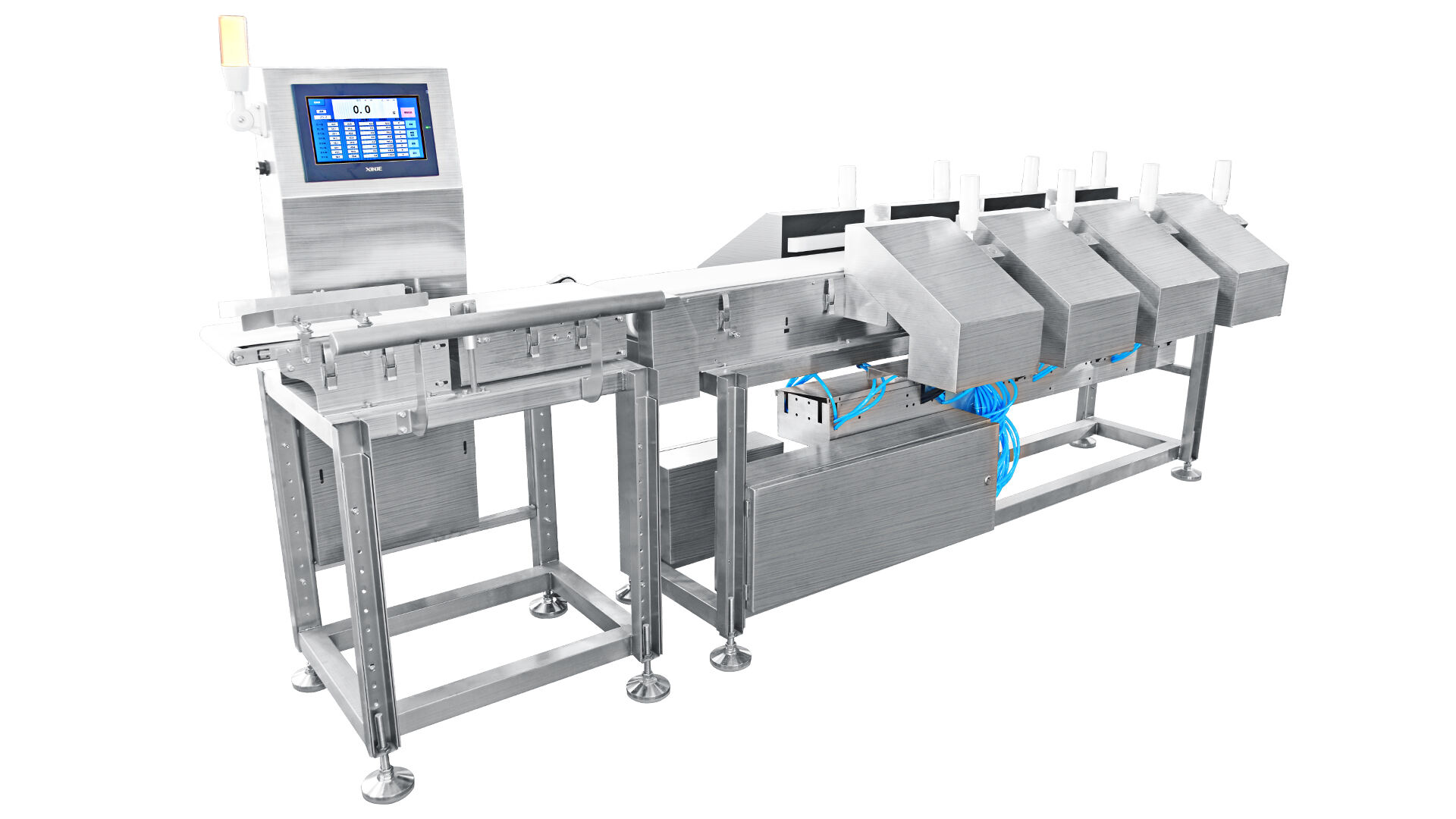

check weighing equipment

Check weighing equipment represents a cornerstone of modern quality control and production efficiency in manufacturing and packaging operations. These sophisticated systems combine precision weighing technology with automated inspection capabilities to ensure products maintain consistent weight specifications. The equipment typically consists of high-precision load cells, advanced digital processing units, and conveyor systems that enable real-time weight verification at high speeds. Modern check weighers can process hundreds of items per minute while maintaining accuracy levels down to fractions of a gram. They incorporate features such as automatic rejection mechanisms for out-of-specification products, data logging capabilities for quality assurance documentation, and intuitive user interfaces for easy operation. These systems are particularly valuable in industries such as food and beverage, pharmaceuticals, and consumer goods manufacturing, where weight accuracy directly impacts both regulatory compliance and customer satisfaction. The technology employs dynamic weighing principles, allowing for continuous product flow while maintaining precise measurements, and often includes features like automatic calibration, multiple weight zones, and advanced filtering algorithms to compensate for environmental factors and vibration.