checkweigher suppliers

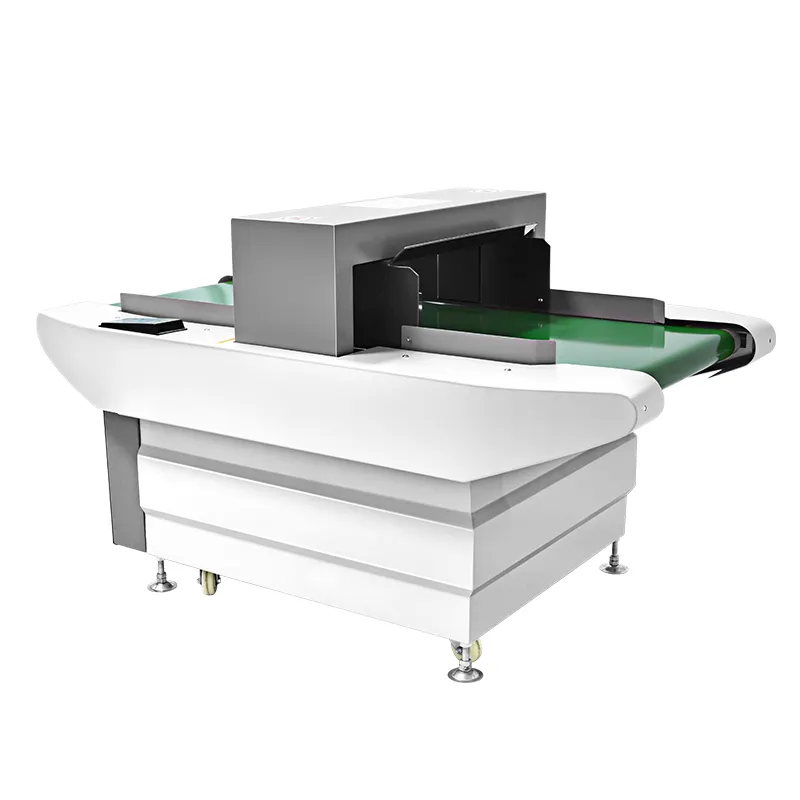

Checkweigher suppliers play a crucial role in modern manufacturing and quality control processes by providing advanced weighing solutions that ensure product consistency and regulatory compliance. These suppliers offer sophisticated systems that automatically verify the weight of packaged products at high speeds during the production process. Their equipment combines precision weighing technology with advanced software algorithms to deliver accurate measurements within milliseconds. Modern checkweighers feature dynamic weight verification capabilities, integrated metal detection options, and user-friendly interfaces that simplify operation and maintenance. These systems are designed to handle various product sizes and shapes, making them versatile for different industries including food and beverage, pharmaceuticals, and consumer goods. Suppliers typically provide comprehensive solutions that include installation, calibration, training, and ongoing technical support. Their systems often incorporate data management capabilities for production monitoring, quality control documentation, and compliance reporting. Advanced features such as automatic rejection mechanisms for non-compliant items, statistical analysis tools, and remote monitoring capabilities enhance production efficiency and quality assurance. Leading suppliers also ensure their equipment meets international standards and regulations while offering customization options to address specific industry requirements.