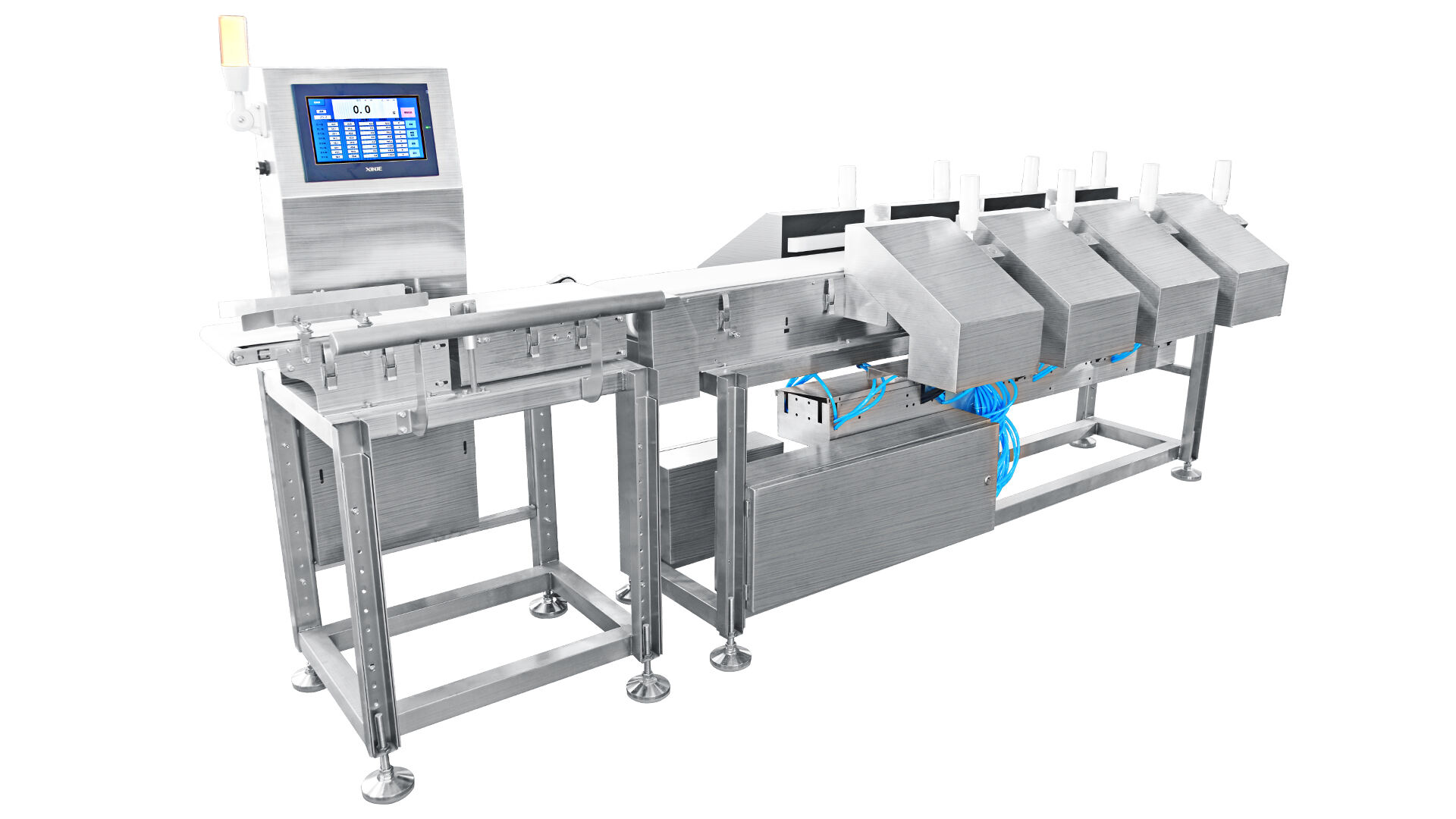

industrial checkweigher manufacturers

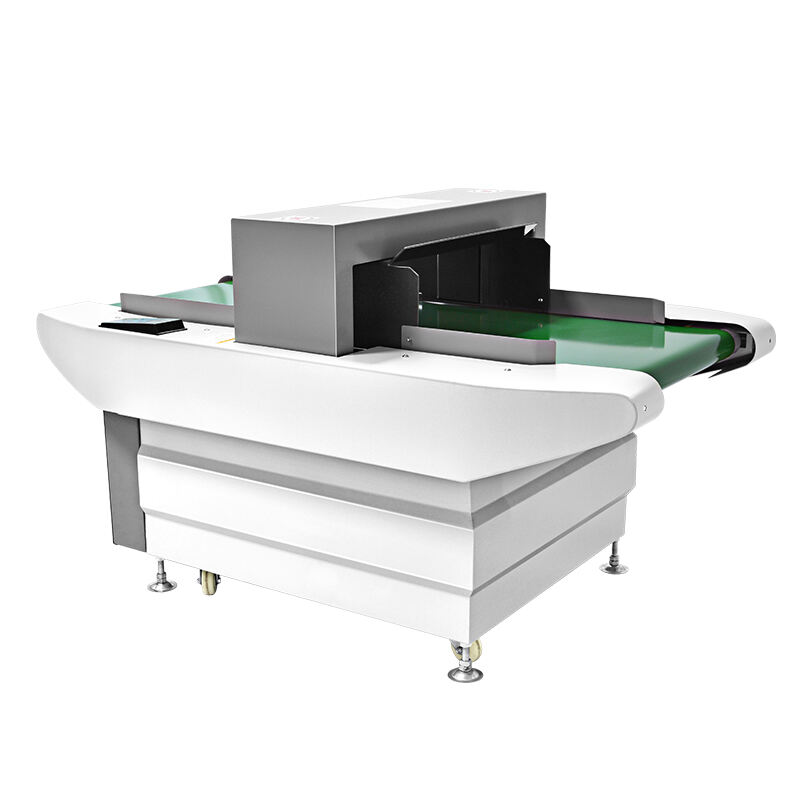

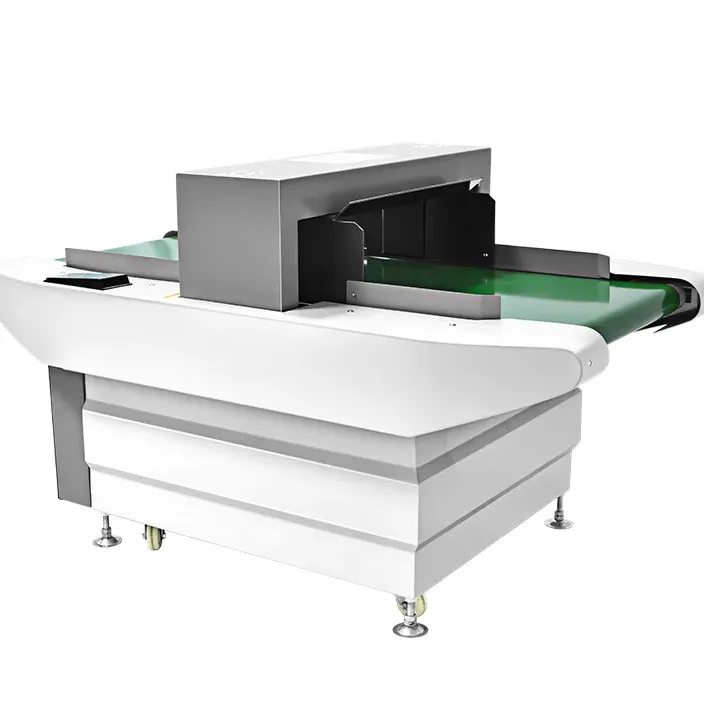

Industrial checkweigher manufacturers play a crucial role in modern manufacturing by producing sophisticated weighing systems that ensure product quality and compliance. These manufacturers develop and supply high-precision equipment that automatically weighs products during the production process, verifying that each item meets specified weight requirements. Their systems incorporate advanced technologies such as dynamic weighing capabilities, high-speed processing units, and precise load cells that can handle various product sizes and shapes. The equipment they produce typically features user-friendly interfaces, automated rejection mechanisms for non-compliant items, and data collection capabilities for quality control and reporting purposes. These manufacturers focus on creating solutions that integrate seamlessly into existing production lines, offering features like multi-lane configurations, washdown designs for hygiene-sensitive environments, and compatibility with industry 4.0 standards. They serve diverse sectors including food and beverage, pharmaceuticals, cosmetics, and chemical industries, providing customized solutions that meet specific industry regulations and requirements. Additionally, these manufacturers often offer comprehensive service packages, including installation, calibration, maintenance, and technical support to ensure optimal performance and longevity of their equipment.