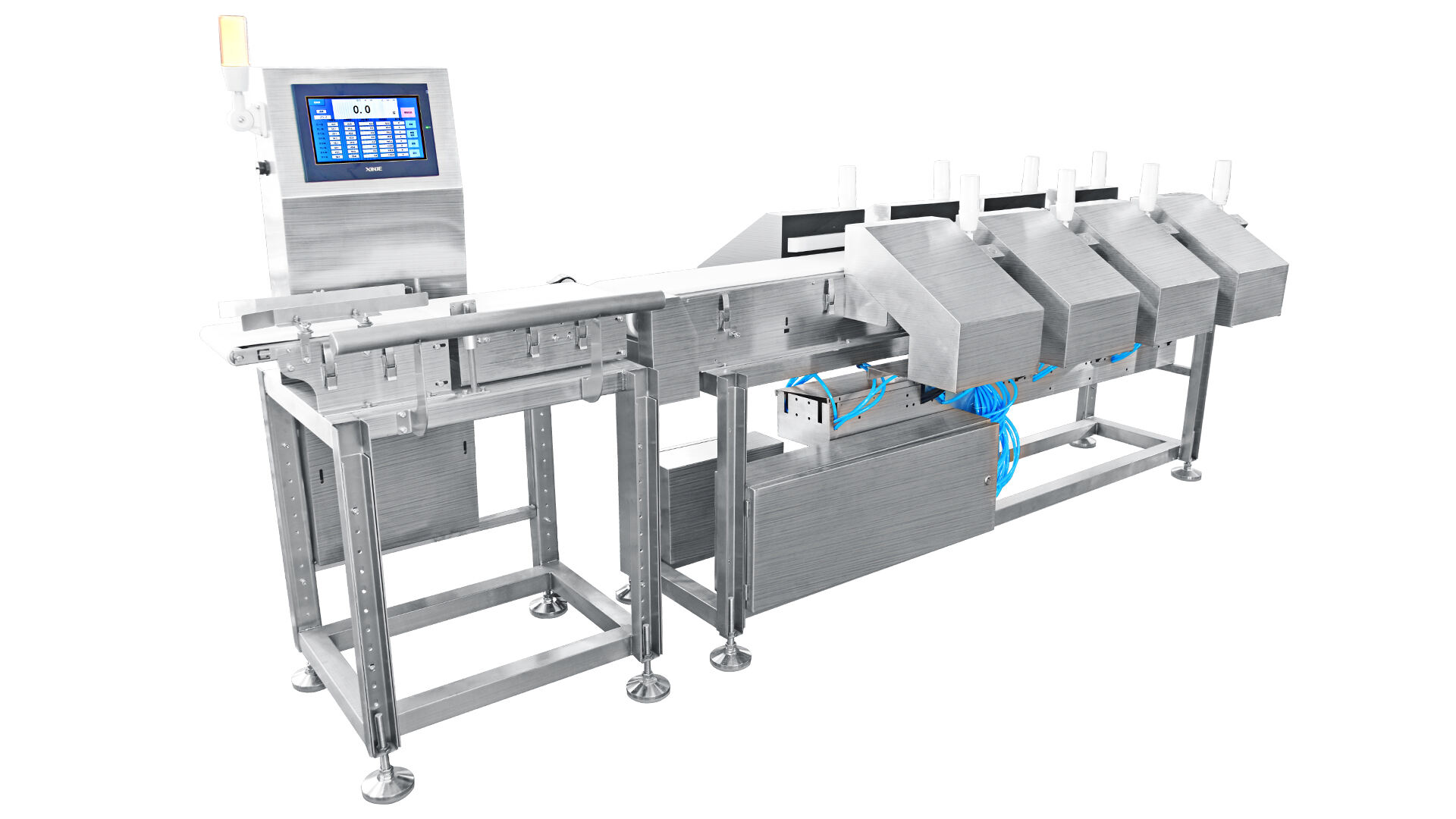

durable precision checkweigher

The durable precision checkweigher represents a cutting-edge solution in weight verification technology, designed to meet the demanding requirements of modern manufacturing and packaging operations. This sophisticated system combines robust construction with high-precision weighing capabilities, ensuring accurate measurements in challenging industrial environments. The checkweigher features advanced load cell technology that delivers precise weight measurements at high speeds, with accuracy levels reaching up to 0.01g depending on the model specifications. Its durable stainless steel construction protects against harsh environmental conditions, while the sealed electronics housing ensures reliable operation in wet or dusty settings. The system incorporates intelligent software that enables real-time weight monitoring, data collection, and automated product rejection for items outside specified parameters. With processing speeds capable of handling up to 400 items per minute, this checkweigher maintains exceptional accuracy while supporting high-throughput production lines. The system's modular design allows for easy integration into existing production lines and features tool-less belt removal for quick cleaning and maintenance. Additional features include an intuitive touchscreen interface, multiple product memory settings, and comprehensive reporting capabilities for quality control and compliance documentation.