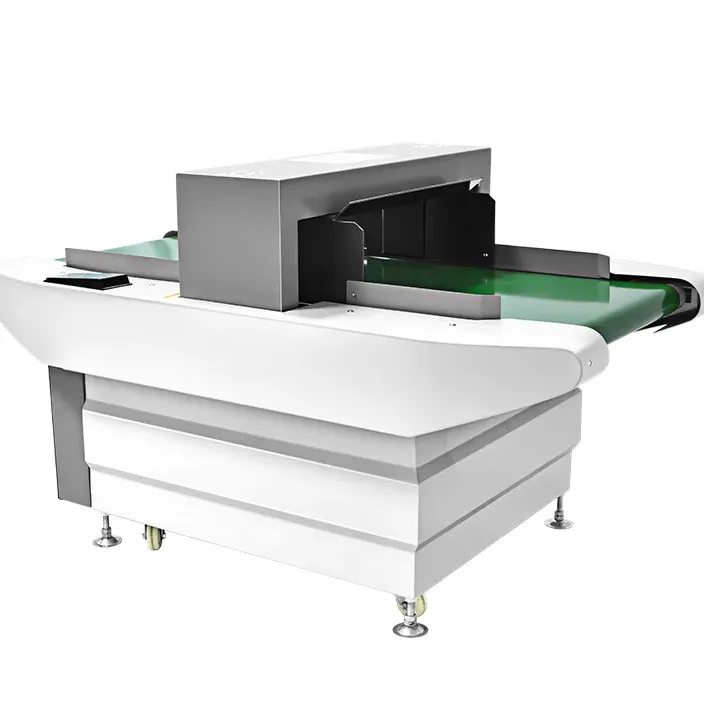

granular food metal detector

The granular food metal detector represents a crucial advancement in food safety technology, specifically designed to detect and remove metallic contaminants from granular food products. This sophisticated detection system utilizes advanced electromagnetic technology to identify ferrous, non-ferrous, and stainless steel particles with exceptional precision. The detector operates by generating a balanced electromagnetic field through which granular food products pass. When metal contaminants enter this field, they create a disturbance that triggers an immediate response mechanism. The system features adjustable sensitivity settings to accommodate different product types and production requirements, while maintaining consistent detection accuracy. Equipped with digital signal processing capabilities, it can effectively distinguish between product effect and genuine metal contamination, significantly reducing false rejections. The detector's robust construction includes food-grade stainless steel components, ensuring compliance with stringent hygiene standards. Its user-friendly interface allows operators to easily adjust settings, monitor performance, and access comprehensive inspection data. The system's high-speed processing capability enables it to maintain optimal detection performance even at maximum production speeds, making it ideal for high-volume food processing operations.