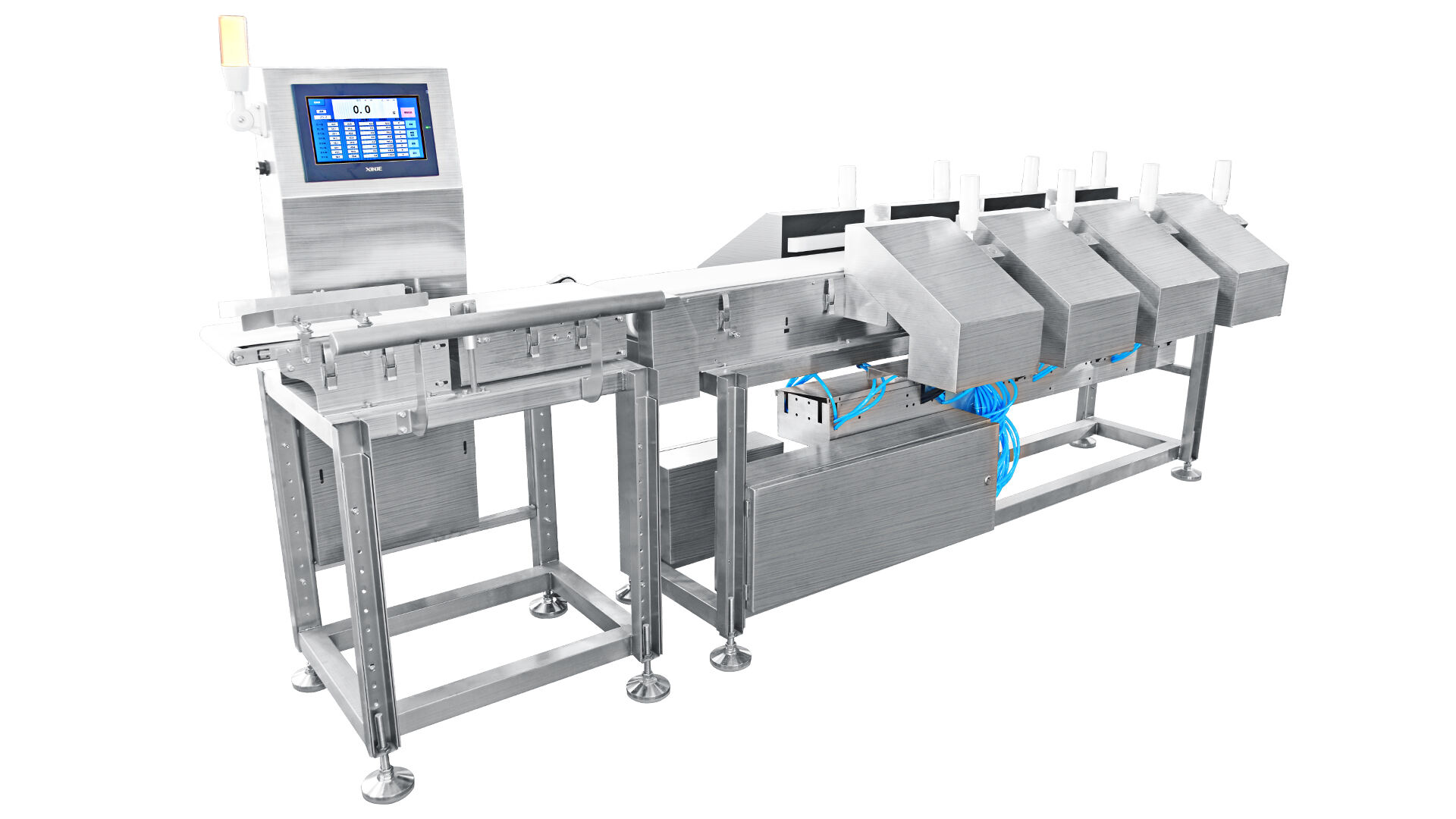

high-precision granular metal detector

The high-precision granular metal detector represents a cutting-edge solution in quality control and safety inspection for granular materials. This sophisticated device utilizes advanced electromagnetic technology to detect and identify metallic contaminants with exceptional accuracy, even in high-speed processing environments. The system employs multiple detection coils that create a powerful electromagnetic field, capable of identifying ferrous, non-ferrous, and stainless steel particles as small as 0.3mm in diameter. Its intelligent digital signal processing algorithms ensure reliable detection while minimizing false rejections. The detector features an intuitive touchscreen interface that allows operators to easily adjust sensitivity settings and access comprehensive inspection reports. Designed for seamless integration into existing production lines, the detector includes automatic reject mechanisms that efficiently remove contaminated products without disrupting the flow of production. The system's robust construction meets IP69K standards for washdown protection, making it ideal for demanding food processing environments. It also incorporates advanced features such as automatic balance control, phase adjustment, and multi-frequency technology to maintain optimal performance across varying product conditions. The detector's versatility makes it suitable for inspecting a wide range of granular products, including grains, powders, nuts, coffee beans, and plastic pellets, ensuring compliance with HACCP, FDA, and other regulatory requirements.