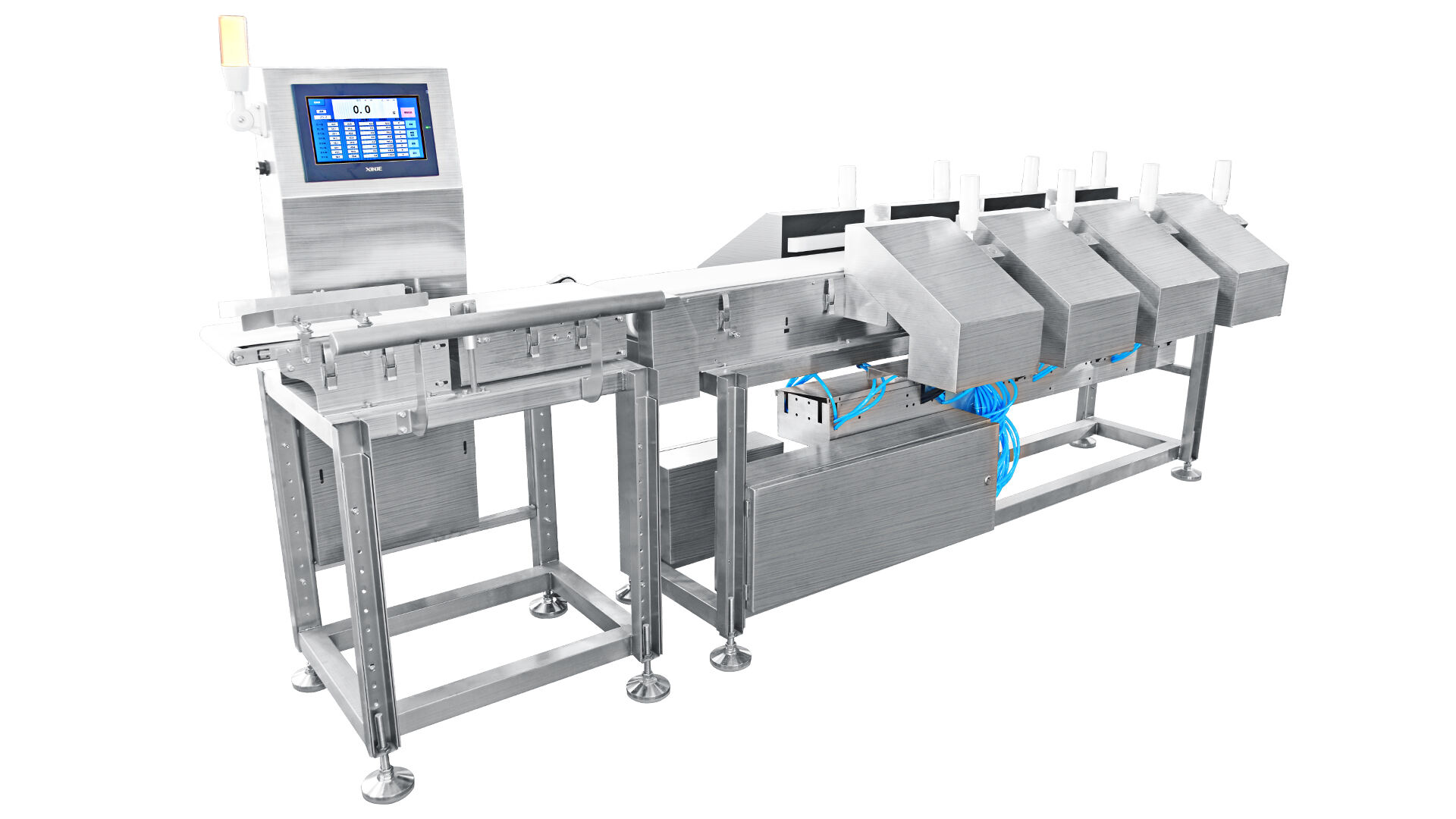

advanced detection for metal impurities

Advanced detection for metal impurities represents a cutting-edge approach to ensuring product quality and safety across various industries. This sophisticated technology employs multiple detection methods, including X-ray fluorescence (XRF), atomic absorption spectroscopy (AAS), and inductively coupled plasma mass spectrometry (ICP-MS), to identify and quantify metallic contaminants with unprecedented precision. The system can detect trace amounts of metals down to parts per billion (ppb) levels, making it essential for industries such as pharmaceuticals, food and beverage, electronics, and environmental monitoring. The technology features automated sampling systems, real-time analysis capabilities, and advanced data processing algorithms that enable continuous monitoring and rapid results reporting. The detection process is non-destructive and requires minimal sample preparation, allowing for high-throughput screening of materials. Additionally, the system incorporates smart calibration protocols and quality control measures to ensure consistent and reliable results. Its versatility allows for the analysis of various sample types, including liquids, solids, and semi-solid materials, while maintaining high accuracy and reproducibility. The technology also includes comprehensive data management systems that facilitate regulatory compliance and documentation requirements.