food grade metal detector manufacturer

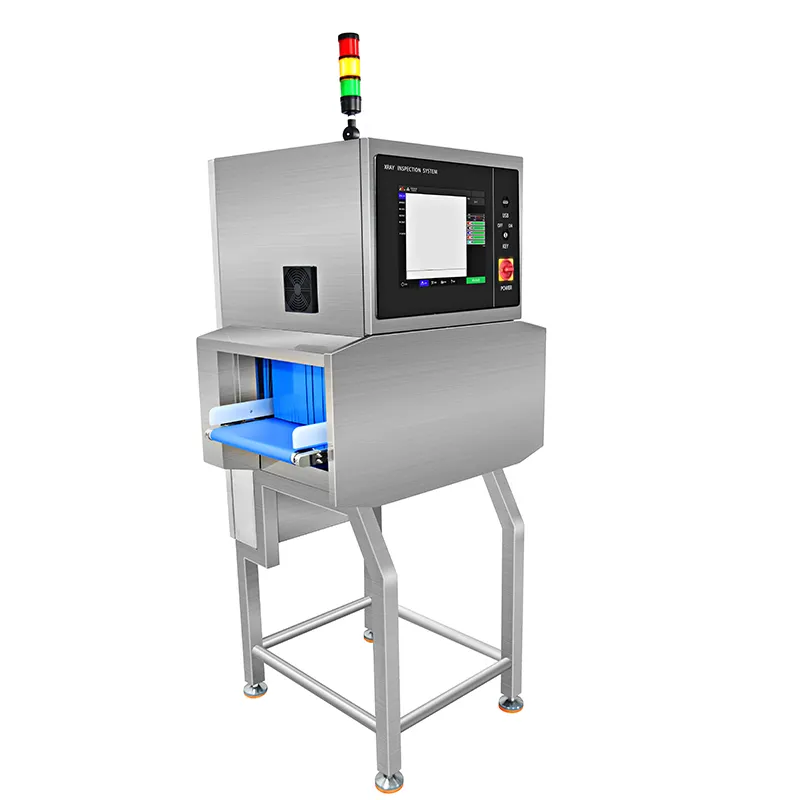

Food grade metal detector manufacturers specialize in producing advanced detection systems that ensure the safety and quality of food products during the manufacturing process. These manufacturers develop sophisticated equipment that can identify and remove metallic contaminants, including ferrous, non-ferrous, and stainless steel particles, from food products with exceptional precision. Their systems incorporate state-of-the-art electromagnetic technology and digital signal processing to achieve maximum sensitivity while minimizing false rejections. The equipment is designed to meet strict hygiene standards, featuring stainless steel construction, IP69K protection ratings, and easy-to-clean surfaces that comply with FDA and HACCP requirements. These manufacturers offer various models suitable for different food processing environments, from dry goods to wet and frozen products. They provide comprehensive solutions that include automatic rejection systems, data logging capabilities for compliance documentation, and user-friendly interfaces for efficient operation. The technology continuously evolves to meet emerging industry challenges, with manufacturers investing in research and development to enhance detection accuracy and reliability. Their equipment undergoes rigorous testing and certification processes to ensure compliance with international food safety standards and regulations.