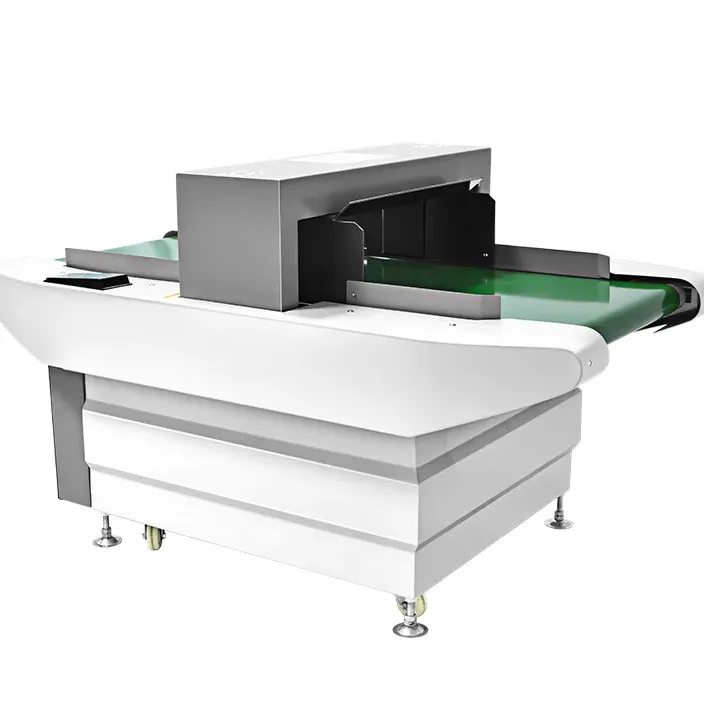

food grade metal detector price

Food grade metal detector prices vary significantly based on their capabilities, sophistication, and manufacturing quality. These essential food safety devices typically range from $3,000 to $25,000, with premium models featuring advanced detection technology commanding higher prices. The cost reflects the integration of high-frequency electromagnetic fields, precise detection algorithms, and durable stainless steel construction suitable for food processing environments. Modern food grade metal detectors incorporate multiple frequency ranges to detect ferrous, non-ferrous, and stainless steel contaminants, with sensitivity levels reaching down to 0.5mm in optimal conditions. The price also accounts for additional features such as automatic calibration systems, data logging capabilities, and compliance with HACCP and other food safety regulations. Manufacturers often include installation, training, and initial calibration in the price package, ensuring optimal performance from day one. The investment in a quality metal detector is justified by its role in protecting brand reputation, ensuring consumer safety, and meeting regulatory requirements. When considering the price, it's essential to factor in the long-term value, including maintenance costs, reliability, and the potential savings from preventing contaminated products from reaching the market.