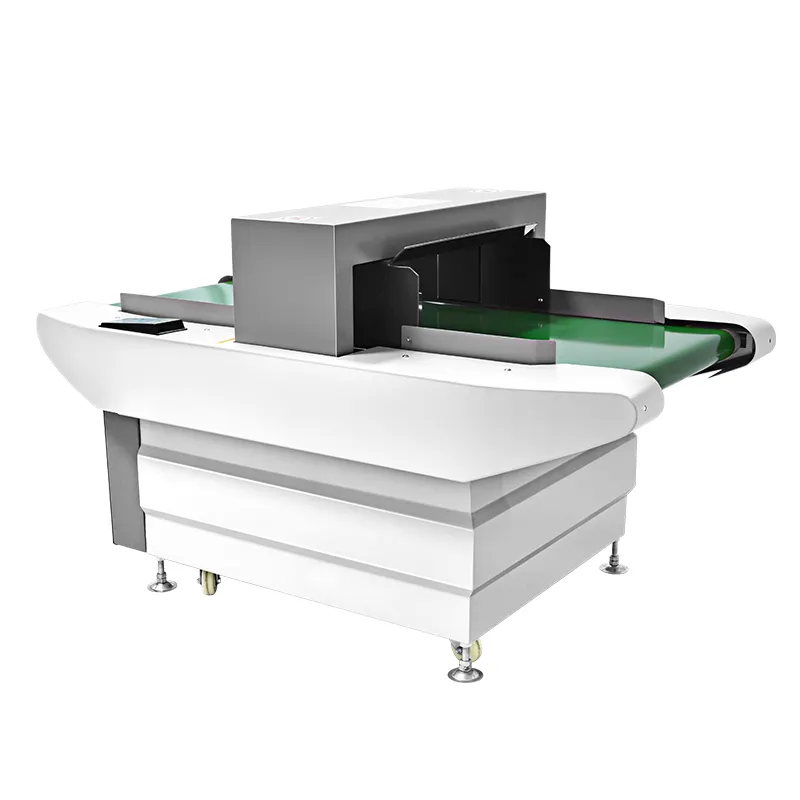

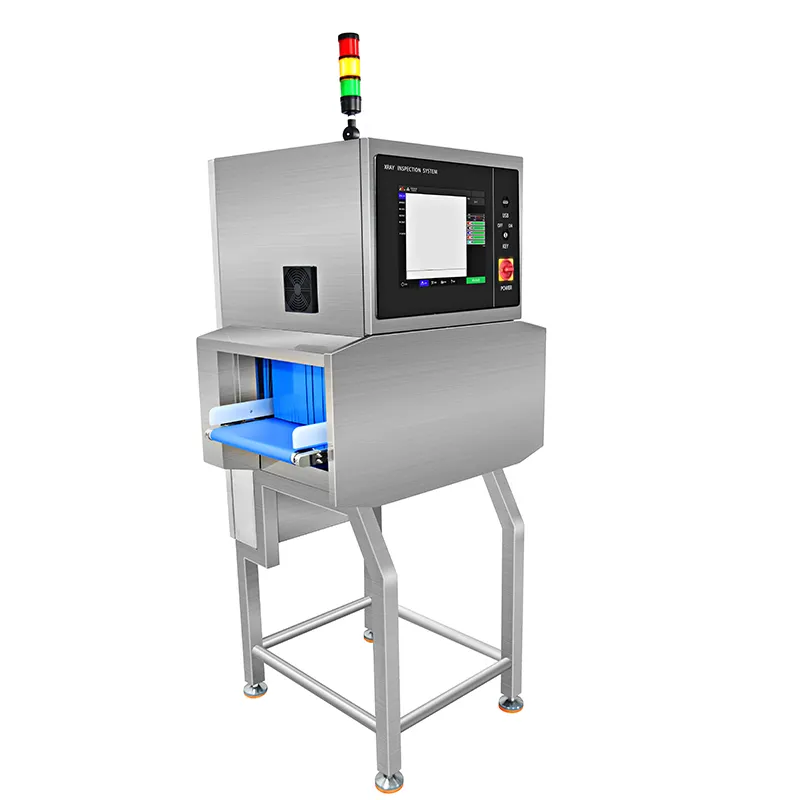

meat x ray machine price

The meat x ray machine price represents a critical investment consideration for food processing facilities seeking to enhance their quality control measures. These sophisticated inspection systems typically range from $20,000 to $50,000, depending on specifications and capabilities. Modern meat x ray machines incorporate advanced imaging technology that can detect various contaminants, including metal fragments, bone particles, and other foreign materials, with precision down to 0.3mm. The pricing structure often reflects the machine's detection accuracy, throughput capacity, and additional features such as multi-lane inspection capabilities and automated rejection systems. Manufacturers generally offer various models at different price points, allowing businesses to select equipment that aligns with their specific production requirements and budget constraints. The total investment consideration should include installation costs, operator training, maintenance packages, and potential software upgrades. Many suppliers provide flexible financing options and leasing arrangements to make these essential quality control systems more accessible to businesses of all sizes. The return on investment is typically realized through reduced product waste, minimized recall risks, and enhanced brand protection.