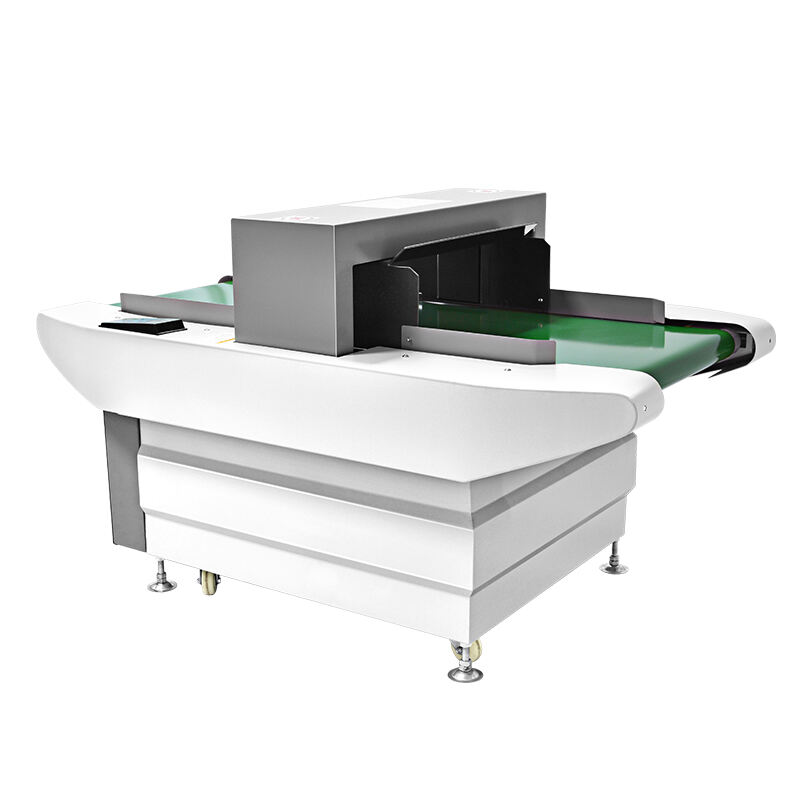

x ray machine for meat

X-ray machines for meat inspection represent a crucial advancement in food safety technology, offering comprehensive internal inspection capabilities for meat products. These sophisticated systems utilize advanced X-ray technology to detect various foreign materials, including metal fragments, glass, stones, and dense plastic materials that may contaminate meat products during processing. The machine operates by emitting low-dose X-rays that penetrate the meat while sophisticated detectors analyze the absorption patterns to create detailed images of the product's interior. This technology can identify contaminants as small as 0.3mm in size, depending on the density and composition of both the foreign object and the meat product. The system's high-resolution imaging capabilities allow for real-time inspection of products moving along the production line at speeds of up to 300 feet per minute. Additionally, these machines can simultaneously perform quality control functions such as mass measurement, fat analysis, and product shape verification. Modern X-ray systems for meat inspection are equipped with advanced software that enables automated detection and rejection of contaminated products, maintaining detailed inspection records for traceability and compliance purposes. The technology is designed to operate in harsh food processing environments, with hygienic construction that meets stringent food safety standards and allows for easy cleaning and maintenance.