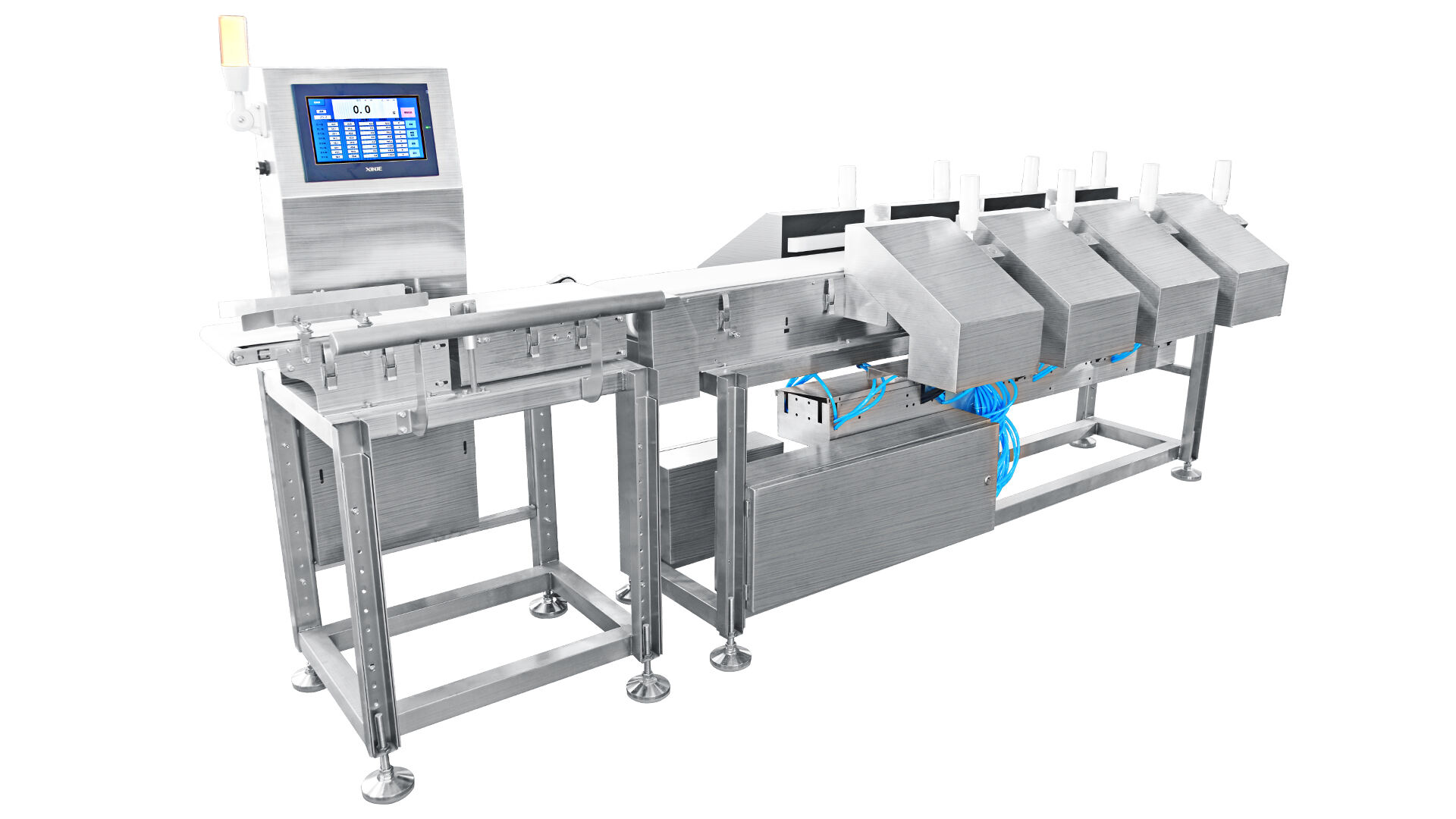

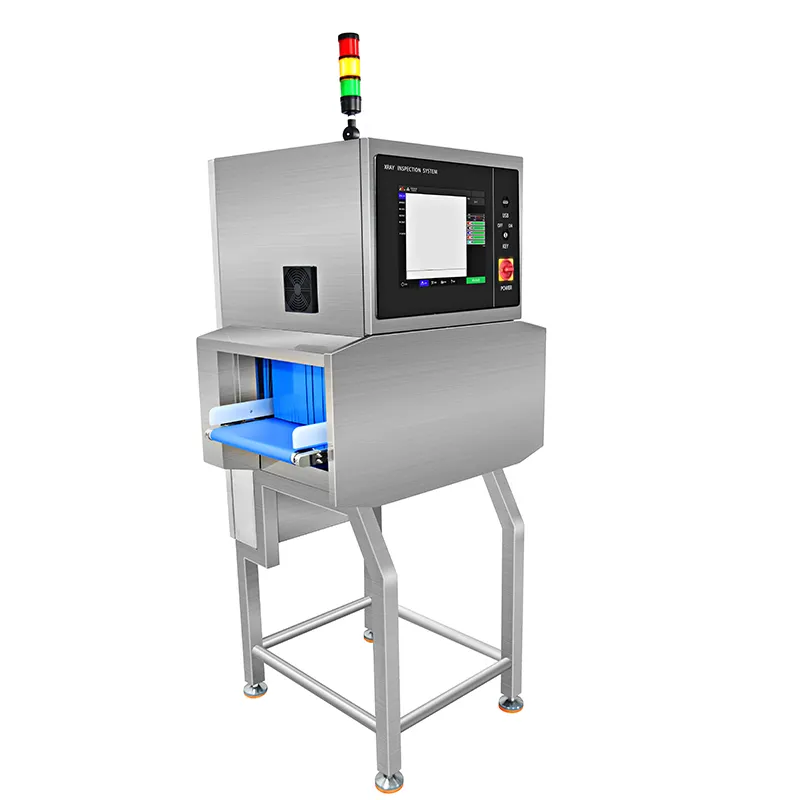

metal detector machine food

The metal detector machine food represents a crucial quality control technology in modern food processing, designed to detect and remove metallic contaminants from food products during production. This sophisticated equipment utilizes advanced electromagnetic field technology to identify various types of metal, including ferrous, non-ferrous, and stainless steel particles, ensuring product safety and compliance with food safety regulations. The system operates by creating a balanced electromagnetic field through which food products pass. When metal contaminants enter this field, they cause a disturbance that triggers an immediate response, typically resulting in automatic rejection of contaminated items. Modern food metal detectors feature digital signal processing, automatic calibration systems, and multi-frequency technology that enables precise detection even in challenging products with high moisture content or variable temperatures. These machines are engineered to maintain consistent performance in demanding industrial environments, offering IP69K protection ratings for high-pressure washdown scenarios. The technology includes advanced features such as data logging capabilities for quality assurance documentation, user-friendly touchscreen interfaces for easy operation, and network connectivity for remote monitoring and control. Applications span across various food industry sectors, from raw ingredient inspection to final packaged product verification, making these machines indispensable in bakeries, meat processing facilities, dairy operations, and ready-to-eat food production lines.