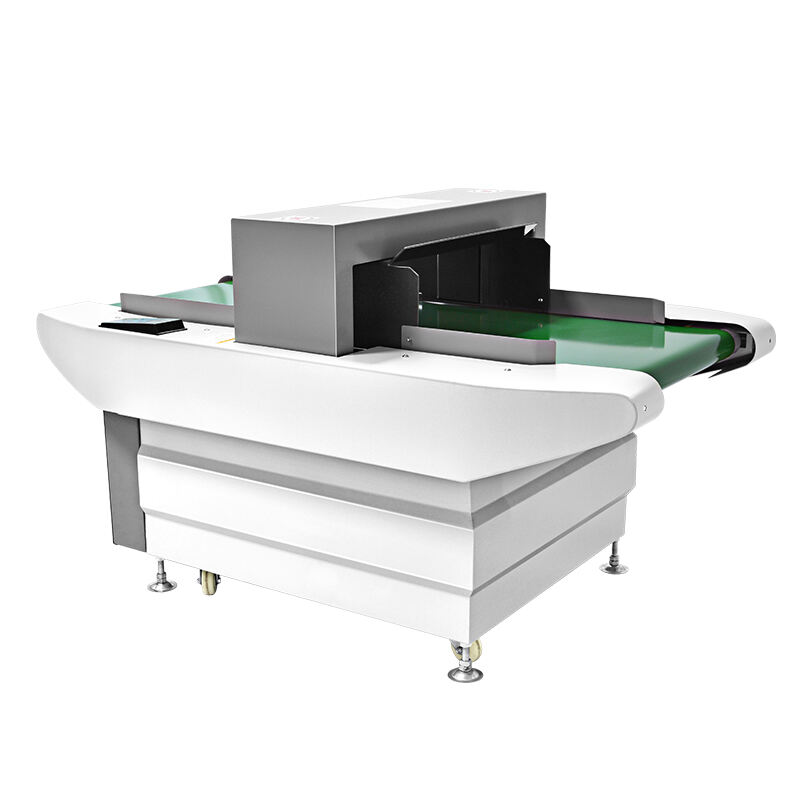

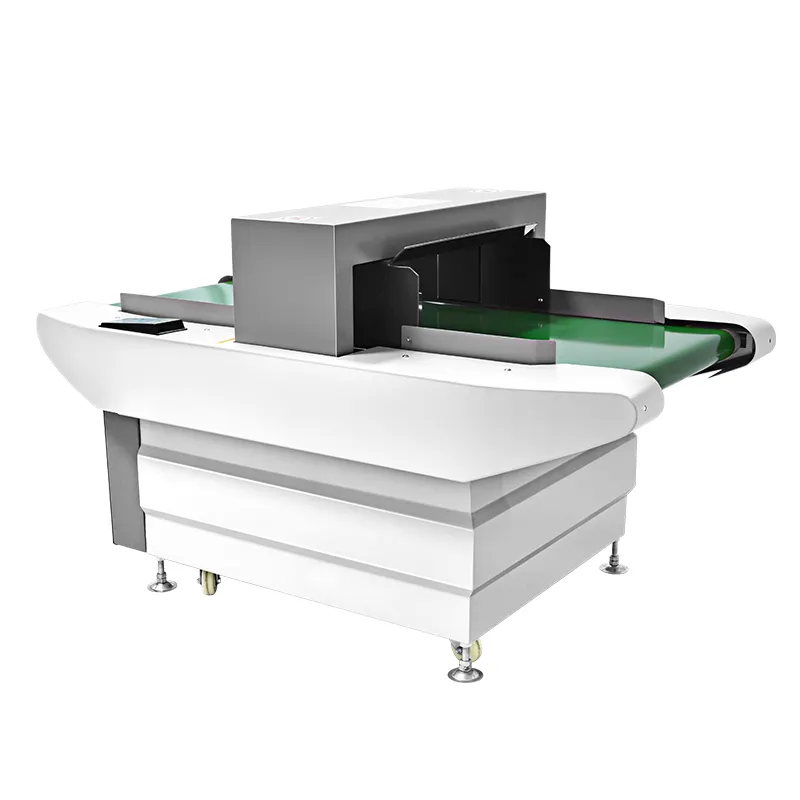

x ray inspection for food factory

X-ray inspection systems in food factories represent a cutting-edge solution for ensuring product safety and quality control in food manufacturing processes. These sophisticated systems utilize advanced X-ray technology to detect and identify various contaminants including metal fragments, glass shards, stone particles, and dense plastic materials that might compromise food safety. The technology operates by passing products through a controlled X-ray beam, creating detailed images that are analyzed in real-time by sophisticated software algorithms. These systems can inspect products through various packaging materials, including metal containers, offering comprehensive inspection capabilities without disrupting the production flow. The technology goes beyond simple contamination detection, as modern X-ray systems can simultaneously perform multiple quality checks, including measuring product mass, monitoring fill levels, detecting missing or broken products, and identifying packaging defects. With resolutions down to 0.3mm, these systems can detect remarkably small foreign bodies, ensuring the highest standards of food safety. The technology integrates seamlessly into existing production lines and can operate at high speeds, maintaining productivity while ensuring thorough inspection of every product.