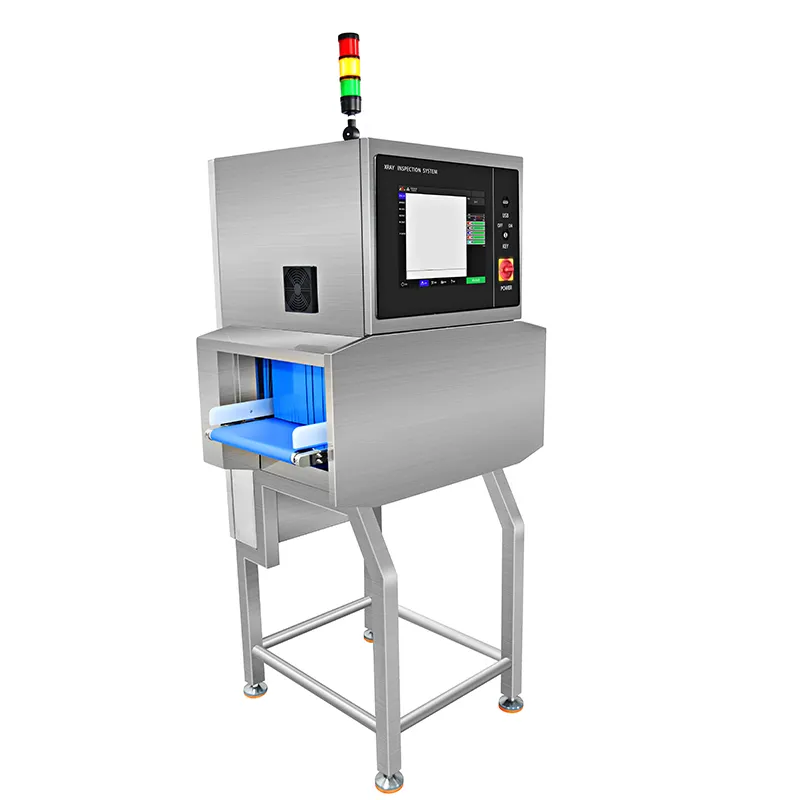

industrial x ray food detector

Industrial X-ray food detectors represent cutting-edge technology in food safety and quality control. These sophisticated systems utilize advanced X-ray technology to detect and identify various contaminants within food products during the manufacturing process. The equipment can detect metal fragments, glass shards, dense plastic, stones, and other foreign materials that might compromise food safety. Operating through a conveyor belt system, these detectors generate detailed images of food products in real-time, allowing for immediate identification of contaminated items. The technology employs powerful image processing algorithms that can distinguish between product and foreign materials based on density differences. Modern X-ray food detectors feature adjustable sensitivity settings, enabling detection of contaminants as small as 0.3mm in size. They operate at high speeds, processing up to 300 items per minute while maintaining accuracy. These systems also offer additional quality control functions, such as mass measurement, seal inspection, and fill-level verification. The equipment complies with international food safety standards and regulations, including HACCP and FDA requirements. With user-friendly interfaces and automated rejection systems, these detectors ensure consistent product quality while minimizing production disruptions.