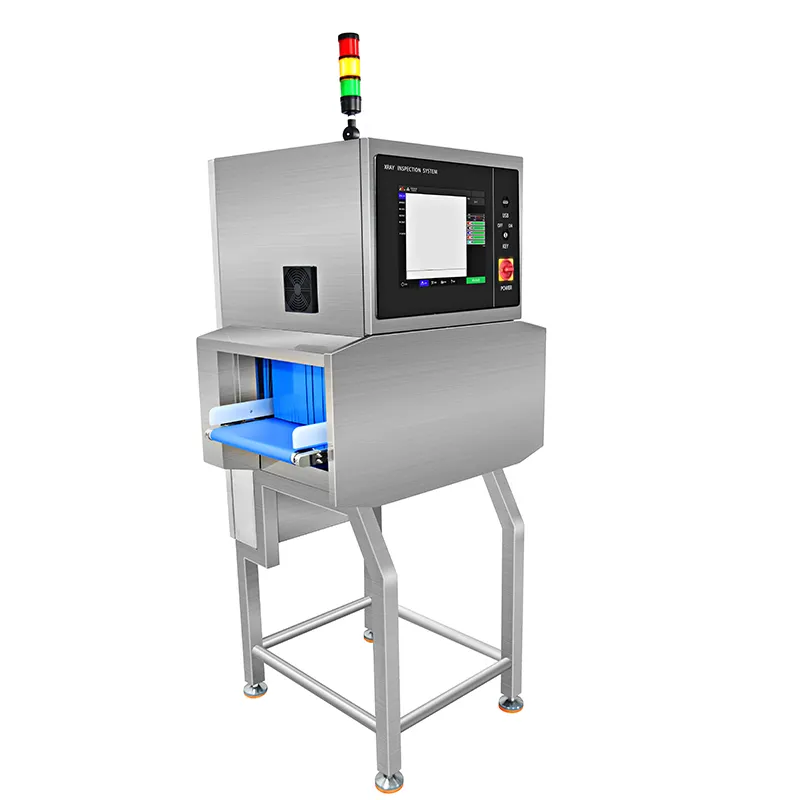

արդյունաբերական սննդի ռենտգեն դետեկտոր

Արդյունաբերական X-ճառագայթային սննդի հայտնաբերիչները ներկայացնում են սննդի անվտանգության և որակի վերահսկման առաջատար տեխնոլոգիաներ։ Այս բարդ համակարգերն օգտագործում են արդիական X-ճառագայթային տեխնոլոգիա՝ սննդամթերքի մեջ աղտոտող տարբեր նյութեր հայտնաբերելու և նույնականացնելու համար արտադրության ընթացքում։ Սարքավորումները կարող են հայտնաբերել մետաղական մասեր, ապակու շերտեր, խիտ պլաստիկ, փոքր քարեր և այլ օտար մարմիններ, որոնք կարող են վտանգել սննդի անվտանգությունը։ Կոնվեյերային համակարգի միջոցով աշխատելիս այս հայտնաբերիչները իրական ժամանակում ստեղծում են սննդամթերքի մանրամասն պատկերներ՝ հնարավորություն տալով անմիջապես նույնականացնել աղտոտված ապրանքները։ Տեխնոլոգիան օգտագործում է հզոր պատկերի մշակման ալգորիթմներ, որոնք խտության տարբերության հիման վրա տարբերում են արտադրանքը և օտար մարմինները։ Ժամանակակից X-ճառագայթային սննդի հայտնաբերիչներն ունեն կարգավորվող զգայունության կարգավորումներ, որոնք թույլ են տալիս հայտնաբերել 0,3 մմ չափսի աղտոտող նյութեր։ Նրանք աշխատում են բարձր արագությամբ՝ մեկ րոպեում մշակելով մինչև 300 ապրանք՝ ապահովելով ճշգրտություն։ Այս համակարգերն առաջարկում են նաև լրացուցիչ որակի վերահսկման ֆունկցիաներ, ինչպիսիք են զանգվածի չափումը, փակման ստուգումը և լցման մակարդակի հաստատումը։ Սարքավորումները համապատասխանում են միջազգային սննդի անվտանգության ստանդարտներին և կանոններին, այդ թվում՝ HACCP և FDA-ի պահանջներին։ Օգտատերերի հարմար ինտերֆեյսներով և ավտոմատացված մերժման համակարգերով ապահովված՝ այս հայտնաբերիչներն ապահովում են արտադրանքի հաստատուն որակը՝ նվազագույնի հասցնելով արտադրության խափանումները։