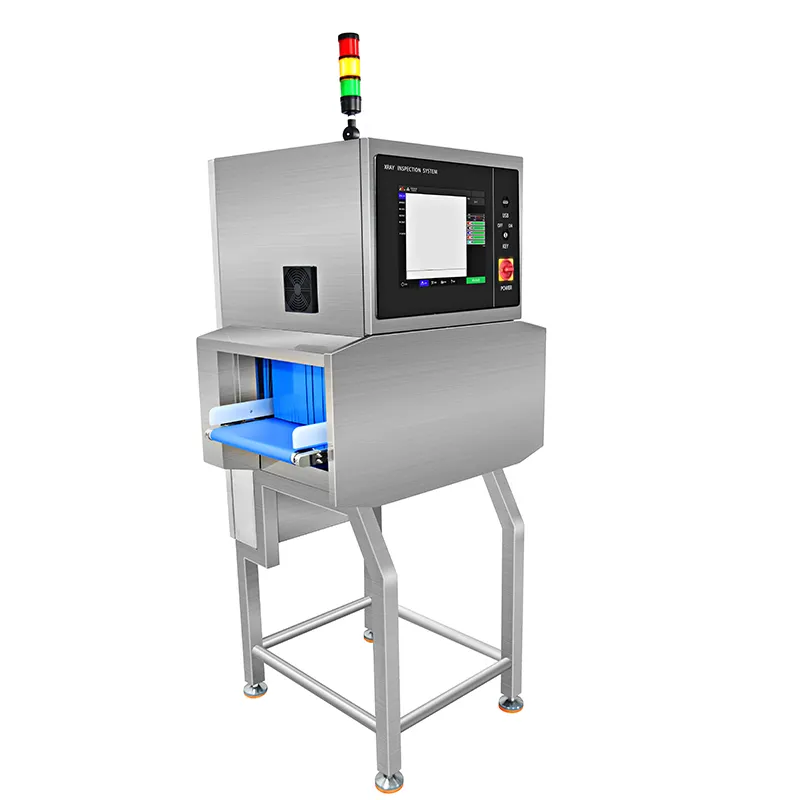

արդյունաբերական սնունդի ռենտգենային մեքենա

Արդյունաբերական սննդի ռենտգենային մեքենաները ներկայացնում են սննդի անվտանգության եւ որակի վերահսկման առաջատար տեխնոլոգիաներ: Այս համակարգերը օգտագործում են առաջադեմ ռենտգենային տեխնոլոգիան՝ հայտնաբերելու հավանական աղտոտիչները եւ նախորդից ավելի ճշգրտությամբ ստուգելու սննդամթերքները։ Մեքենաները կարող են հայտնաբերել տարբեր օտար նյութեր, ներառյալ մետաղը, ապակին, քարը, ոսկուն եւ փաթեթավորված սննդամթերքի մեջ գտնվող բարձր խտության պլաստիկները: Այս մեքենաները, որոնք աշխատում են փոխադրող գոտիային համակարգի միջոցով, արտադրանքը ստուգում են իրական ժամանակում եւ ստեղծում մանրամասն թվային պատկերներ, որոնք անմիջապես վերլուծվում են համակարգչային ալգորիթմներով: Տեխնոլոգիան կարող է հայտնաբերել 0,3 մմ-ից փոքր աղտոտիչներ' կախված արտադրանքի խտությունից եւ փաթեթավորման տեսակից: Բացի աղտոտվածության հայտնաբերումից, այս համակարգերը կատարում են նաեւ որակի վերահսկման գործառույթներ, ինչպիսիք են լցման մակարդակի ստուգումը, փաթեթավորման բովանդակության ստուգումը եւ բացակայող կամ կոտրված ապրանքների հայտնաբերումը: Մեքենաները նախագծված են բազմաթիվ անվտանգության հատկանիշներով եւ համապատասխանում են միջազգային սննդի անվտանգության չափանիշներին: Նրանք կարող են րոպեում հարյուրավոր ապրանքներ մշակել ՝ պահպանելով ստուգման հետեւողական որակը, ինչը նրանց իդեալական է դարձնում մեծ ծավալի արտադրության միջավայրերում: Համակարգերը հարմարեցվում են տարբեր սննդամթերքի տեսակների եւ փաթեթավորման ձեւաչափերի համար, ներառյալ մետաղական դանակներ, ապակյա բեռնարկղեր, պլաստիկ բեռնարկղեր եւ ճկուն փաթեթավորում: Տվյալների կառավարման առաջադեմ հնարավորությունները թույլ են տալիս մանրամասն գրանցումներ պահել եւ հետընթաց ապահովել, ինչը կարեւոր է կարգավորումների համապատասխանության եւ որակի ապահովման ծրագրերի համար: