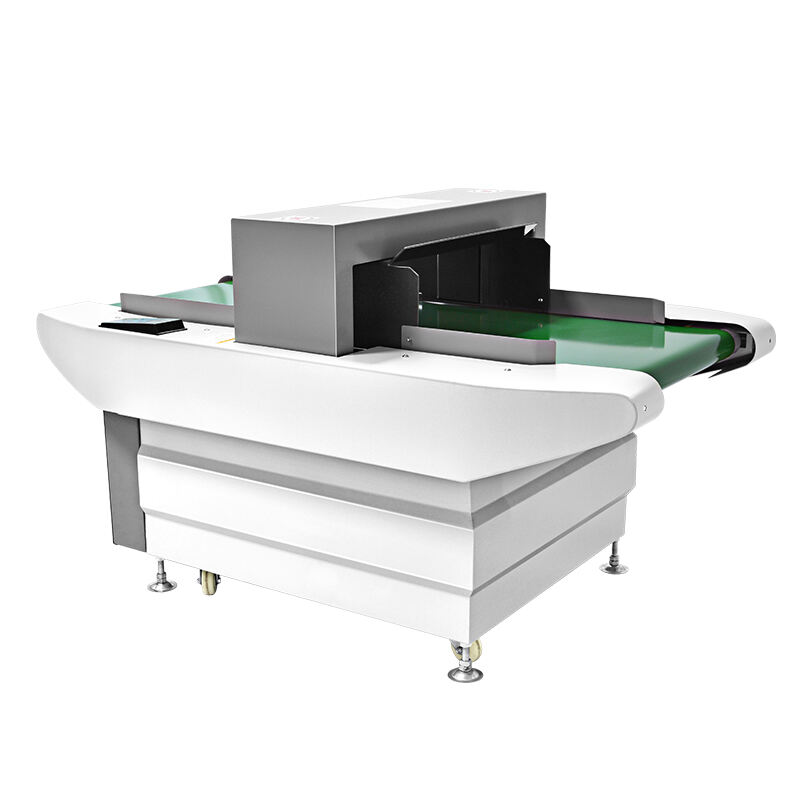

caղաքի մետալազտանիչ մեքենա

Բարձրորակ մետաղային սեպարատոր մեքենան ներկայացնում է արդյունաբերական մշակման գծերում աղտոտվածության հայտնաբերման եւ հեռացման մեջ առաջատար տեխնոլոգիան: Այս բարդ համակարգը օգտագործում է առաջադեմ էլեկտրամագնիսական սենսորներ եւ ճշգրտ սորտավորման մեխանիզմներ տարբեր արտադրանքի հոսքերից մետաղական աղտոտիչները հայտնաբերելու եւ վերացնելու համար: Աշխատելով բացառիկ ճշգրտությամբ, մեքենան կարող է հայտնաբերել եւ առանձնացնել երկաթային, ոչ երկաթային եւ անժանգոտ պողպատի մասնիկները, ապահովելով արտադրանքի մաքրությունը եւ սարքավորումների պաշտպանությունը: Համակարգը պարունակում է թվային ազդանշանների մշակման ամենաարդյունավետ տեխնոլոգիան, որը հնարավորություն է տալիս իրական ժամանակում վերահսկել եւ անմիջապես հեռացնել աղտոտվածությունը' առանց խափանելու արտադրության հոսքը: Նրա ամուր կառուցվածքը, համակցված ինտելեկտուալ ինքնակալիբրիացիոն հնարավորությունների հետ, ապահովում է հետեւողական կատարում տարբեր միջավայրի պայմաններում: Մեքենայի բազմակողմանի դիզայնը հարմար է տարբեր ապրանքատեսակների համար, սկսած փոշուց եւ խնձորներից մինչեւ հեղուկներ, ինչը այն հարմար է դարձնում տարբեր արդյունաբերությունների համար, ներառյալ սննդամթերքի մշակումը, դեղագործությունը, պլաստմասը եւ քիմիական նյութերը: Հասանելիության կարգավորումների եւ մերժման մեխանիզմների միջոցով բարձրակարգ մետաղական սեպարատորը ապահովում է աննախադեպ հայտնաբերման ճշգրտություն ՝ պահպանելով արտադրության օպտիմալ արդյունավետությունը: Համակարգի օգտագործողի համար հարմար ինտերֆեյսը ապահովում է գործառույթի ամբողջական վերահսկողություն եւ մանրամասն աղտոտման զեկույցներ, որոնք հեշտացնում են որակի ապահովման փաստաթղթերը եւ արդյունաբերական ստանդարտների համապատասխանությունը:

![Արկղային գործիքների ].' Համար պատրաստական համալիրի ստուգումների համար](https://shopcdnpro.grainajz.com/category/5221/1574/6ae53ea26af7233f479dcf54bce02766/image.png)