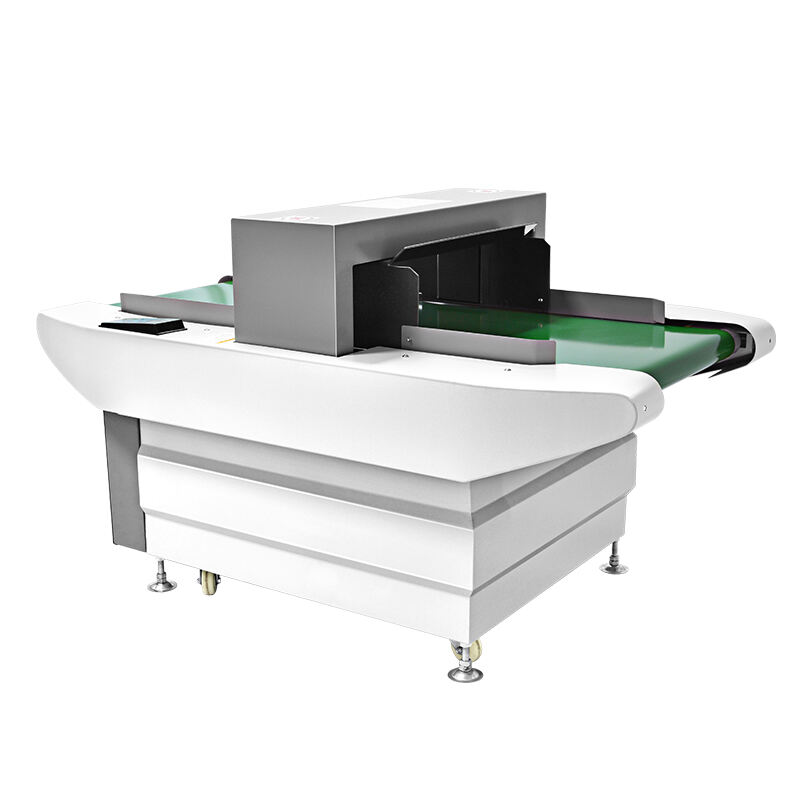

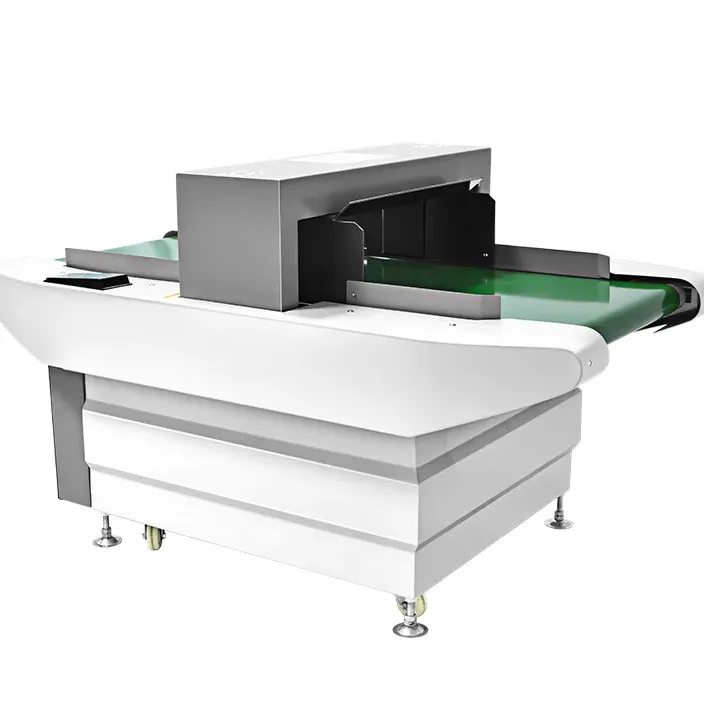

machina automata carnis X ray

Machina automática ad inspectiónem carnis per radios X repraesentat solutionem novíssimam in rébus salútis alimentórum et contróli qualitátis. Hoc systéma subtilissimum technologiam radiórum X adhibet ut contaminántia potentiália detégat et pródúcta carnium scrútétur summa praevisióne. In sistémate cóntinuo velóci operátur, centum pródúcta per minútum tractáre pótest constansque accurátus manens. Machina technologiam biénergéticam radiórum X utitur ut inter matéria orgánica ac inorgánica discernat, ita ut obiecta extranea sicut metállum, vítrum, lápis, fragmenta óssis, et plástica altius densitátis in prodúctis carnium agnóscat. Capacitátes inspectiónis automáticae systématis analysin densitátis, mensúram massae, et recognitiónum formae inclúdunt, ita ut examinátio pródúcti plena fíat. Cum interfácie útente amíca, opératores parametrós detectiónis et gradus sensibilitátis facile adádjustare possunt ad particulas necessitátes satisfaciéndas. Machina méchanismos rejectiónis automátics habet qui pródúcta contamináta statim ex líneā productiónis remóvent, strictásque normás qualitátis servántes. Design castrónis clausi salútem radiatóriam tuétur simulque admissum fácile pro mantiéntione et purgatióne praebet. Systéma etiam capacitátes gestiónis datórum prógressas continet, quae permittunt diligéntem conservatiónum réctum et conformitátem cum regulís salútis alimentórum. Haec technológia in hodiernís fábricis tractándi carnium indispénsabilis facta est, applicatiónum latitúdinem ád inspectiónem crúdae carnis usque ad confirmátiómem pródúcti perfécti complecténs.