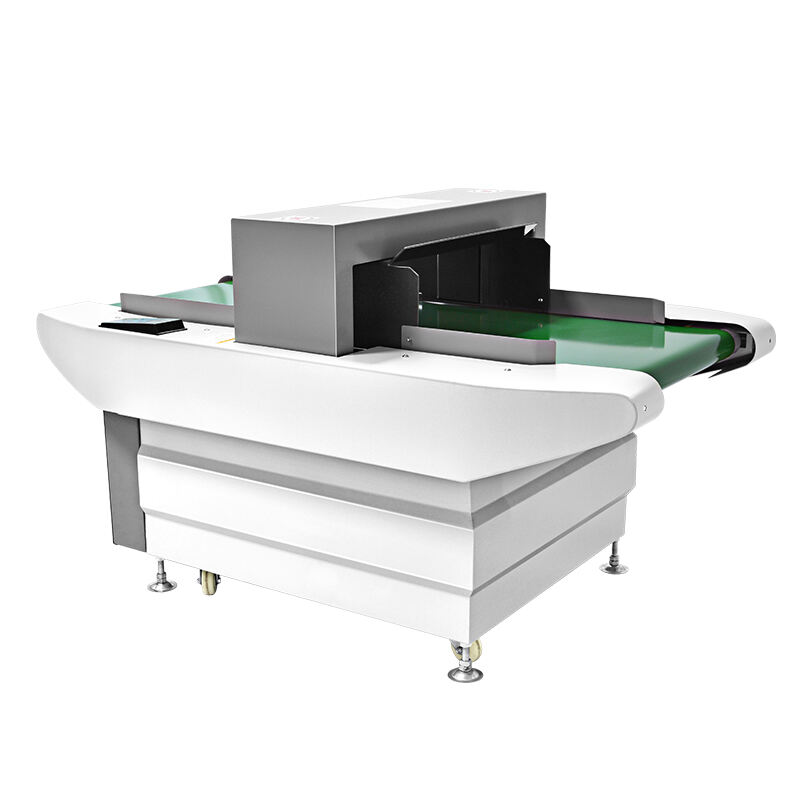

industrialis carnis scanner X-radii

Scanner X-ray carnis industrialis solutionem ultimam generationis praebet ad tutitatem ciborum et conservationem qualitatis in fabricis elaborandi carnem. Haec technologia subtilis usum facit imaginum X-ray progressarum ad detegenda varia contaminamenta et ad servandam constantiam producti per totam lineam productionis. Scanner operatur radiis X minutis per carnem agentibus, imagines expressas generans quae ostendunt obiecta peregrina possibilia ut metallum, vitrum, fragmenta ossium, et alia materiae densa quae tutitatem producti minari possunt. Facultates systematis ad imprimendas imagines altissimae resolutionis permittunt detegere obiecta tam parva quam 0,3 mm, secundum densitatem et compositionem contaminantis et producti carnis. Scanner habet machinationes rejectionis automatas quae statim removebunt producta contaminata e linea productionis, efficacitatem servantem dum tutitatis normae servantur. Praeterea, haec technologia functiones analysionis densitatis continet quae variationes in compositione producti detegere possunt, adiuvantes constantiam in magnitudinibus portionum et contento pinguedinis servare. Scannerae moderni carnei X-ray designati sunt cum interfacebus faciliter utentibus, ut operatoribus facile parametri detectionis mutentur et praestantia systematis tempore vero observetur. Haec systemata saepe cum software gestionis datorum integrantur, quod relationes inspectionis expressas praebet et records plenos ad conservandum propter tutitatem qualitatis et ad legum rationem.