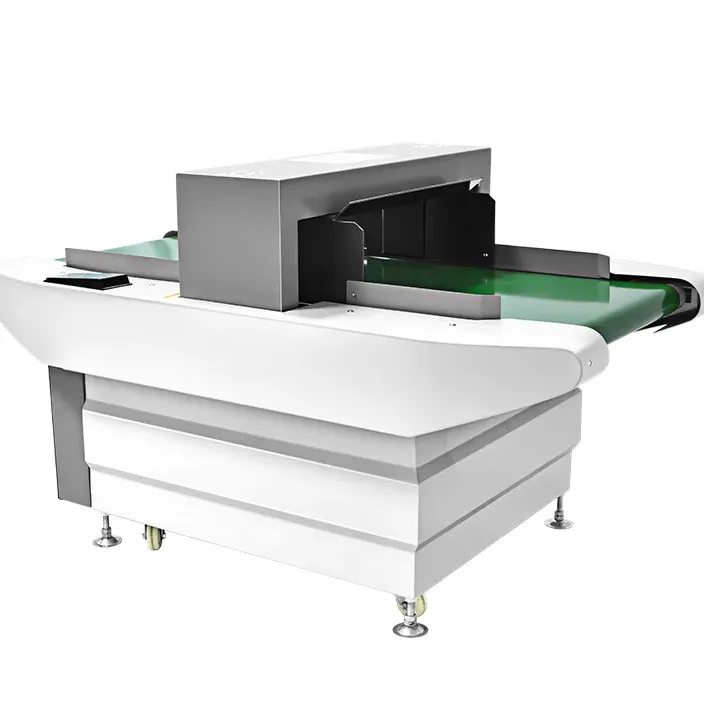

machina radii X detegendi metalli et carnis

Ferri detegens carnis radiographiae machina repraesentat novissimam solutionem in ciborum tuitate et qualitate, coniungens technologiam progressam scandiscandam cum praecisis perceptionis facultatibus. Haec apparatus subtilis utitur duplici inspectionis technologia: ferri detectione tradita et imaginibus radiographiae, praebens examen plenum contaminationis pro productis carnium. Systema operatur emittendo radios radiographiae moderatos qui pertransunt productos carnis simulque utendo campis electromagneticis ad detegendos contaminantes metallicos. Machina varia materia peregrina potest agnoscere, inter quae fragmenta metalli, particulae ossium, fragmenta vitri, et alii contaminantes densi qui tuitatem producti laedere possent. Velociter operando, plura producta simul tractare potest, eadem tamen accurate maxima retinens. Systema sensibilitatis regulabilis habet, qua operatoribus permittitur parametri perceptionis ex characteribus specificis producti ac necessitatibus tuitatis aptare. Software imaginum progressum visualizationem reali tempore praebet productorum scannatorum, qua operatoribus permittitur contaminantes precise agnoscere et locare. Machina e materialibus idoneis ciborum facta est et summas hygienicae normas servat, ita ut adhibenda sit in variis environmentalibus elaborationis carnium. Systemata rejectionis automata includit quae efficienter productos contaminatos e linea productionis removent sine interruptis cursus operis.