separator metalli cadentis venditioni

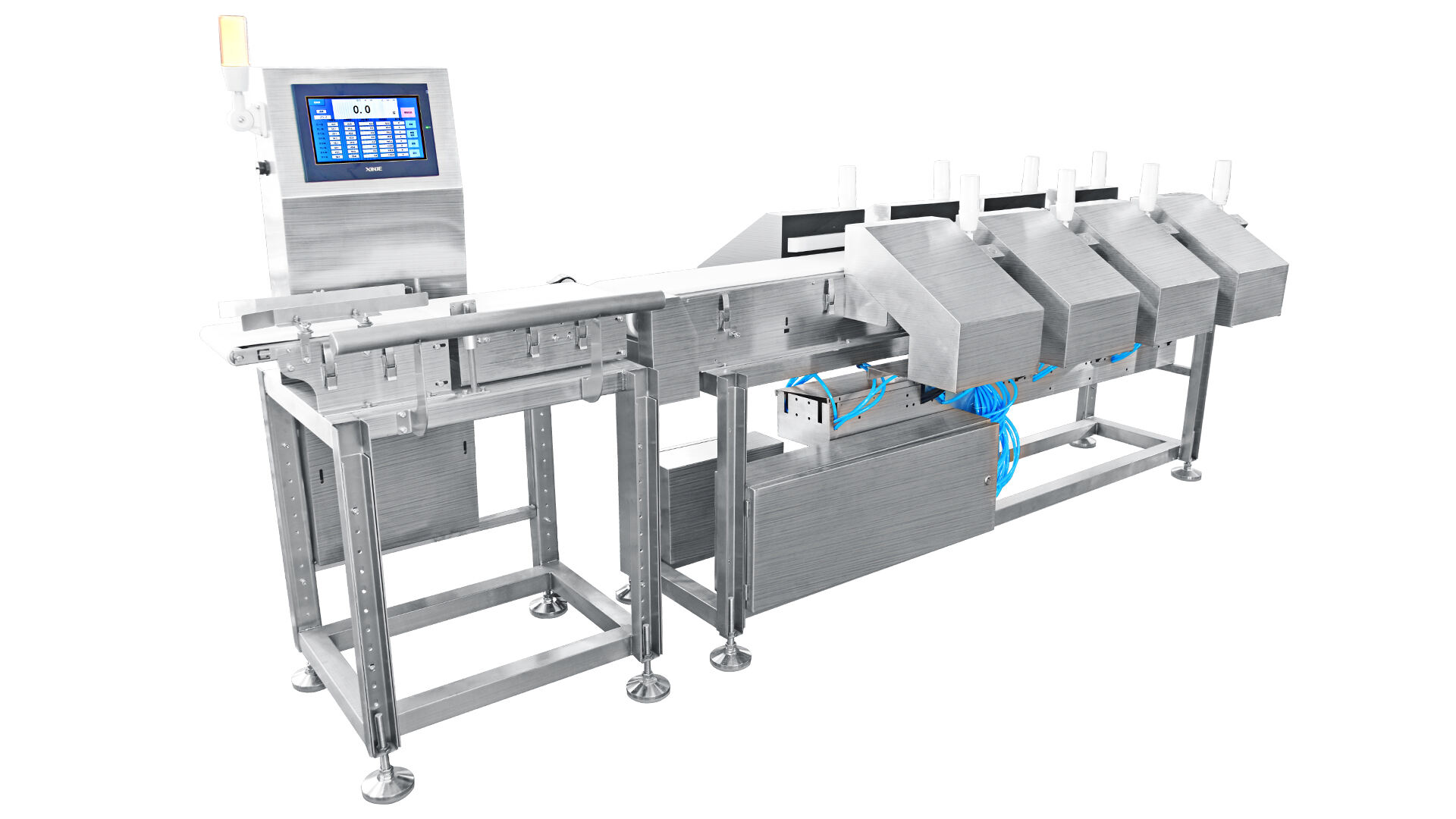

Separator metallorum casus liberis modis est solutio novissima qua deteguntur et tolluntur contaminamenta metallicia e materialibus frugiferis aridis. Hoc systema, quod technology electromagnetic advanced operatur, qualitatem producti superiorum et protectionem machinarum in variis processibus industrialibus pollicetur. Separator systema coil detectionis alti sensus utitur quod metalla ferrosa et non-ferrosa, inclusis particulis ex vitro inox, dum materiales per canalem inspectionis verticalis transeunt, agnoscere potest. Cum contaminatio metallica detegitur, repulsi pneumatica velox statim materiam contaminatam in vas collectionis separatum divertit, dum productum purum fluxum suum normalem continuat. Structura systematis functionem sibi ipsius inspectivam includit quae parametri operationis continue explorat, sic performance certam et rejectiones falsas minimas conservans. In productionis lineas iam existentes integrari valens, separator metallorum casu liberis modis in pluribus industriae rami, inter quos processus alimentorum, plasticae, chemicae et pharmaceuticae, insuperabilis probatur. Constructio eius robusta et ingenium praecisum permittunt varia genera productorum et velocitates transitus tractare, constantiam tamen in accurata detectione servantes.