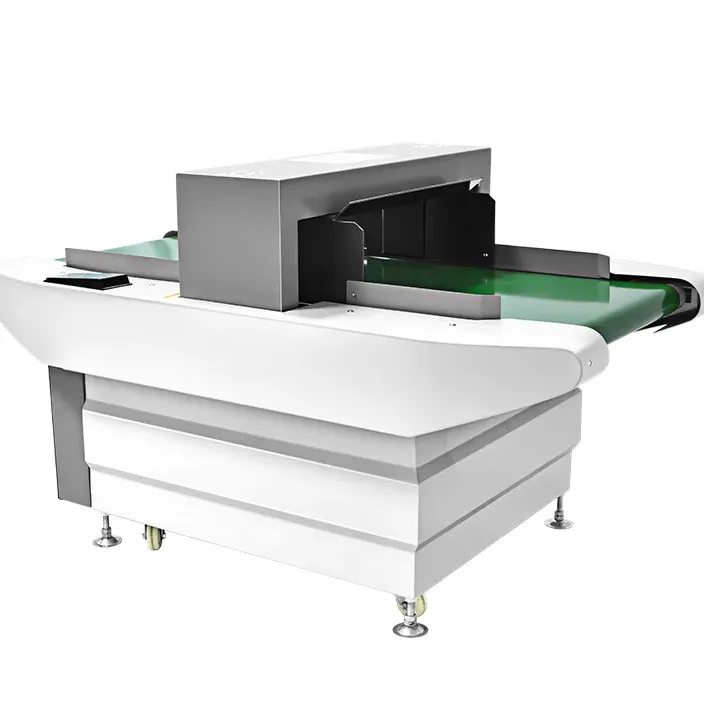

separator metalli cadentis altum efficaciem

Separator metallicus alti rendimenti per casum liberum solutionem repraesentat novissimam ad detegendum et removendum contaminantes metallicos e materialibus frugiferis aridis et fluentibus. Systemate detectionis provecto iuncto cum mechanismis repudiandi velocissimis operans, hic separator qualitatem producti praestantem et protectionem machinarum certam facit. Systema campis magneticis validis et technologia sentiendi exacta utitur ad metalla ferrea et non ferrea, inclusis particulis ex aciero inoxydabili, agnoscenda. Dum materia per canalem inspectionis verticalis separatoris fluit, sensors subtilissimi contaminationem metallicam continuo observant. Post detectionem, systema pneumaticum repudiandi celeriter reagens intra milliseptimas activatur, materia contaminata per effluxum separatum deviando, dum materia pura per processum productionis progreditur. Designatio separatoris variis generibus productorum et rationibus transporti congruit, idoneam efficiens pro industriis velut processandi cibi, plastice, chemicis et pharmaceuticis. Sensibilitate regulabili et facultatibus sese-monitorantibus praeditus, systema pergentem praestationem servat simulque falsa repudianda minuens. Designatio compacta verticalis separatoris spatium minimum postulat et facile in series productionis iam existentes integrari potest, flexibilitatem in installatione et operatione offerens.