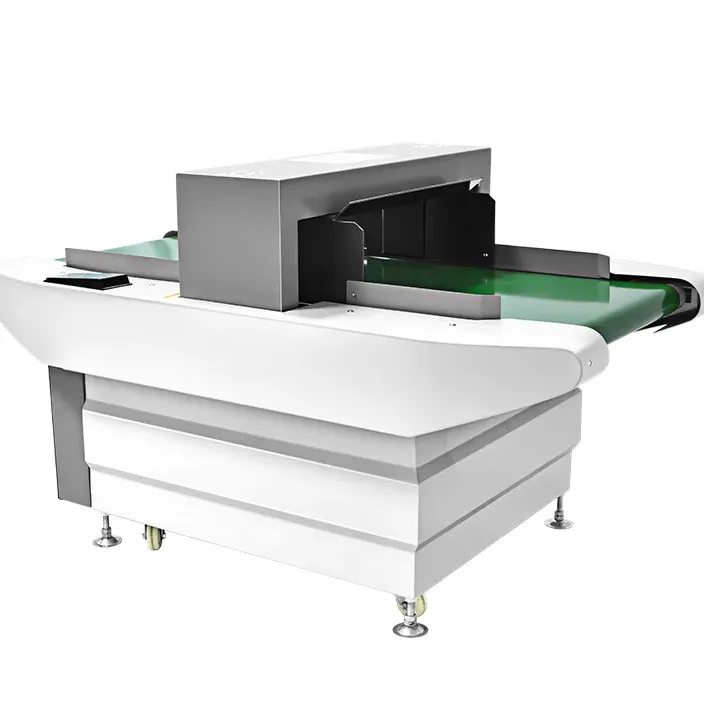

separator metalic cu cădere liberă înalt eficient

Separatorul metalic cu cădere liberă de înaltă eficiență reprezintă o soluție de ultimă generație pentru detectarea și eliminarea contaminanților metalici din materiale vrac uscate și ușor curgătoare. Funcționând printr-un sistem avansat de detecție cuplat cu mecanisme rapide de respingere, acest separator asigură o calitate superioară a produsului și protecția echipamentelor. Sistemul utilizează câmpuri magnetice puternice și tehnologie precisă de senzorizare pentru a identifica atât metalele feroase, cât și cele neferoase, inclusiv particule de oțel inoxidabil. Pe măsură ce materialele trec prin canalul vertical de inspecție al separatorului, senzori sofisticati monitorizează în mod continuu prezența contaminanților metalici. La detectarea unui contaminant, sistemul pneumatic rapid de respingere se activează în milisecunde, deviind materialele contaminate printr-o ieșire separată de evacuare, în timp ce materialele curate continuă procesul de producție. Designul separatorului este adaptabil la diverse tipuri de produse și debite, fiind ideal pentru industrii precum prelucrarea alimentelor, plasticul, chimicalele și farmaceuticele. Cu setări ajustabile ale sensibilității și capabilități de auto-monitorizare, sistemul menține o performanță constantă, minimizând respingerile false. Designul compact vertical al separatorului necesită un spațiu minim și poate fi ușor integrat în liniile de producție existente, oferind flexibilitate în instalare și funcționare.