sistem kontrolli të sigurisë së ushqimit me rreze X

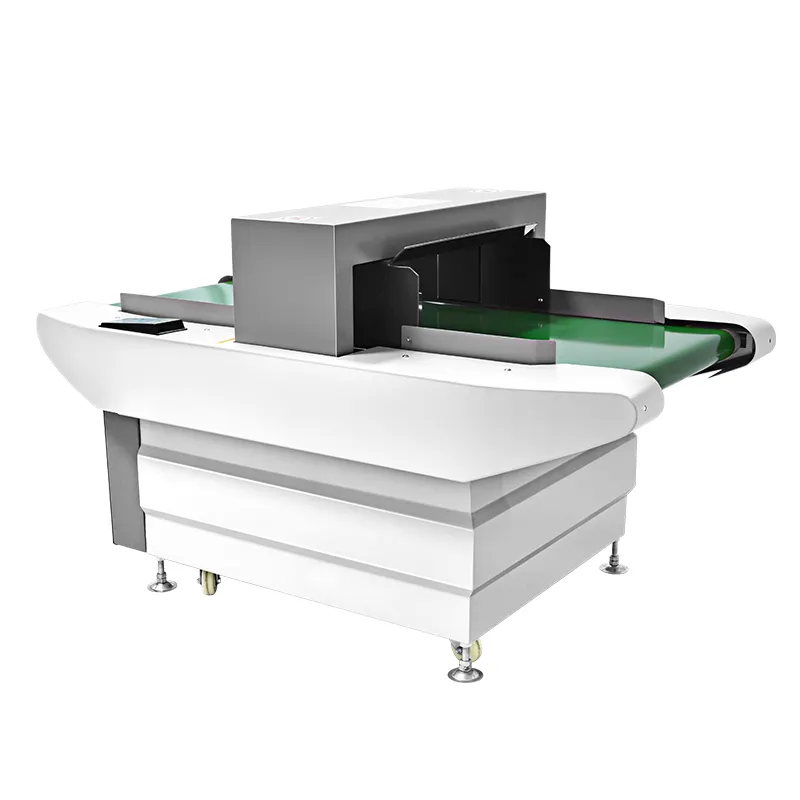

Një sistem inspektimi me rreze x për sigurinë e ushqimit përfaqëson një teknologji të thellë të zhvilluar për të garantuar cilësinë dhe sigurinë e produktit në industrinë e prodhimit të ushqimit. Ky sistem i sofistikuar përdor teknologji të avancuar me rreze x për të zbuluar dhe identifikuar ndotës potencial, përfshirë fragmente metalike, copa qelqi, plastikë të dendur, gurë dhe materiale të huaja të tjera që mund të komprometojnë sigurinë e ushqimit. Sistemi funksionon duke kaluar produkte ushqimore nëpër një rrezë të kontrolluar rreze x, duke krijuar imazhe të hollësishme që analizohen në kohë reale nga algoritme të sofistikuara të softuerit. Këto algoritme mund të zbulojnë variacione në dendësi dhe përbërje, duke lejuar identifikimin e objekteve të huaja aq të vogla sa 0,3 mm në diametër. Teknologjia gjithashtu i lejon prodhuesve të kryejnë kontrolla cilësie, si matja e masës së produktit, kontrolli i integritetit të bllokimet dhe identifikimi i produkteve të munguara ose të dëmtuara. Sistemet moderne të inspektimit me rreze x për sigurinë e ushqimit janë pajisur me interfaqe të thjeshta për përdoruesin, mekanizma të automatizuar hedhjesh në heshtje dhe mundësi të gjerë regjistrimi të dhënash për qëllime gjurmimi dhe përputhjeje. Këto sisteme mund të integrohen në linjat ekzistuese të prodhimit dhe janë të afta të merren me lloje të ndryshme produkte, nga përbërësit e papërpunuar deri te produktet e paketuara, me shpejtësi të larta prodhimi, duke ruajtur saktësi konstante të inspektimit.