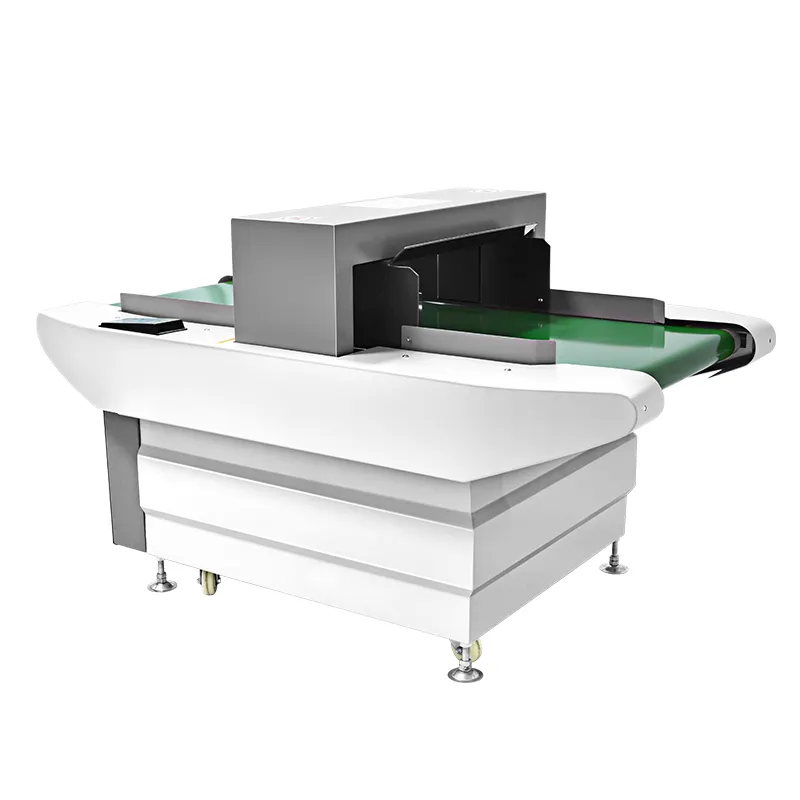

automatic plastic metal separator

The automatic plastic metal separator represents a cutting-edge solution in recycling and material processing industries. This sophisticated equipment utilizes advanced sensing technology and electromagnetic principles to efficiently separate plastic materials from metal contaminants. The system employs multiple detection methods, including eddy current separation and metal detection sensors, to identify and remove both ferrous and non-ferrous metals from plastic waste streams. Operating at high throughput rates, the separator can process large volumes of mixed materials while maintaining exceptional accuracy. The machine features an intelligent control system that automatically adjusts separation parameters based on the input material characteristics, ensuring optimal performance across different waste compositions. Key technological features include high-sensitivity metal detection arrays, precise air-jet ejection systems, and real-time monitoring capabilities. The separator's applications span various industries, including plastic recycling facilities, waste management centers, and manufacturing plants where material purity is crucial. It effectively handles different types of plastic materials, from post-consumer waste to industrial scrap, while maintaining consistent separation quality. The system's automated operation minimizes human intervention, reducing labor costs while increasing processing efficiency and safety.