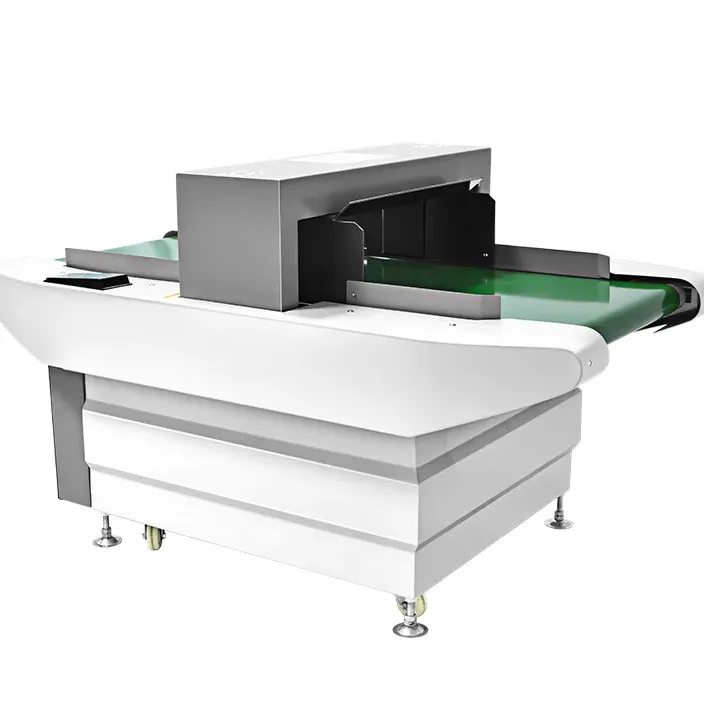

multi-purpose plastic metal separator

The multi-purpose plastic metal separator represents a cutting-edge solution in recycling and material processing industries, designed to efficiently separate plastic and metal components from mixed waste streams. This advanced system employs multiple separation technologies, including magnetic separation, eddy current separation, and sensor-based sorting, to achieve optimal material recovery rates. The separator's sophisticated detection system can identify and sort various types of metals, including ferrous and non-ferrous materials, from different plastic compositions with exceptional accuracy. Operating at high throughput rates, the machine can process several tons of mixed materials per hour while maintaining consistent separation quality. The system features adjustable parameters to accommodate different material sizes and compositions, making it versatile for various industrial applications. Its automated operation includes real-time monitoring and adjustment capabilities, ensuring optimal performance and reducing the need for manual intervention. The separator's robust construction ensures durability in demanding industrial environments, while its modular design facilitates maintenance and upgrades. This technology plays a crucial role in modern recycling facilities, manufacturing plants, and waste management operations, contributing significantly to circular economy initiatives and sustainable resource management.