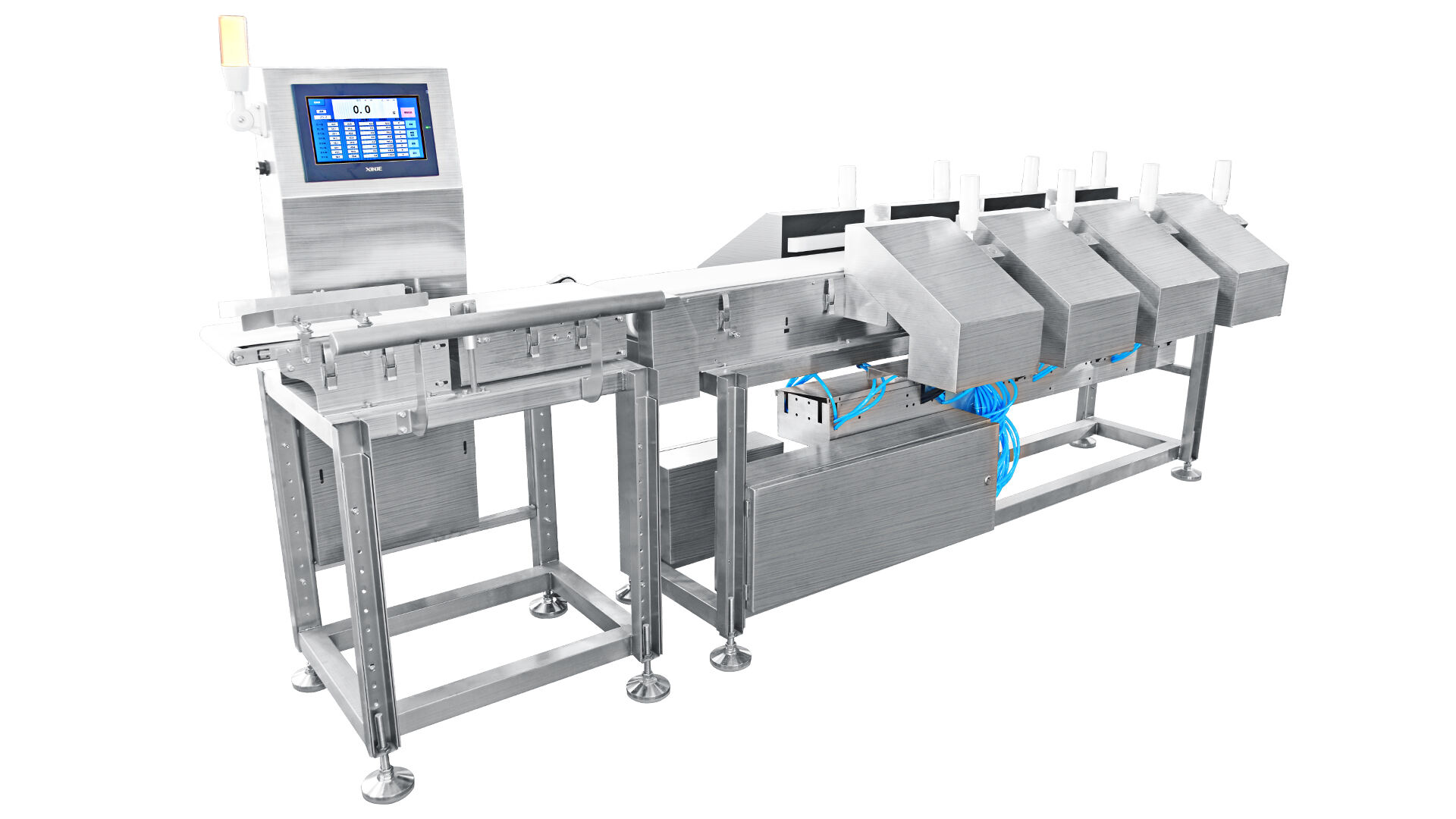

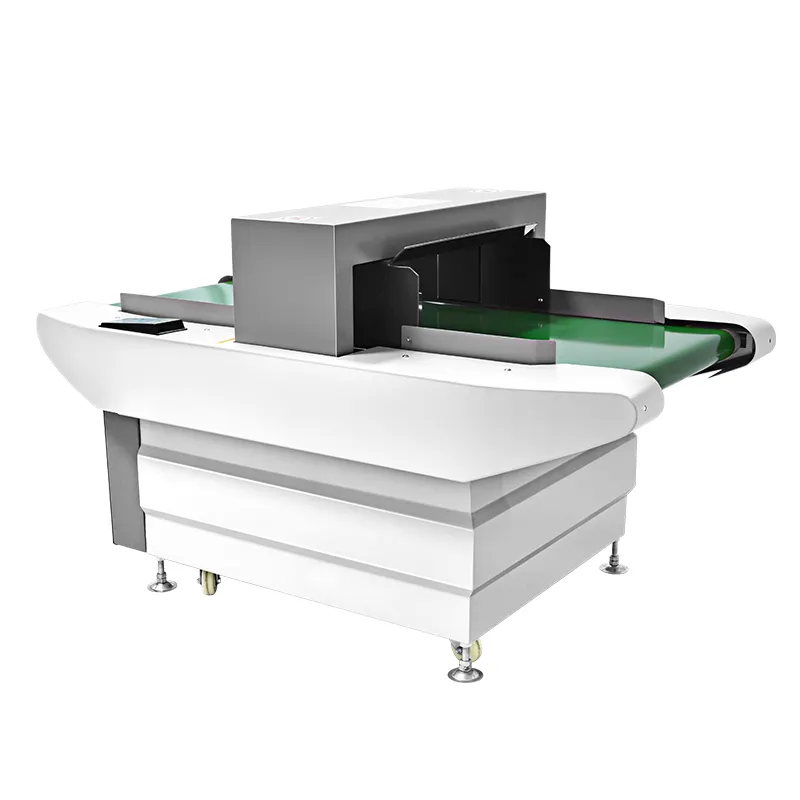

plastic metal separator manufacturer

A plastic metal separator manufacturer specializes in designing and producing advanced sorting systems that effectively separate plastic materials from metal contaminants in various industrial processes. These sophisticated machines utilize cutting-edge electromagnetic and sensor technologies to ensure precise material separation. The equipment typically incorporates multiple detection methods, including metal detectors and advanced imaging systems, to identify and remove both ferrous and non-ferrous metals from plastic waste streams. The manufacturing process involves precision engineering to create robust systems capable of handling high throughput volumes while maintaining exceptional accuracy in separation. These separators are essential in recycling facilities, plastic processing plants, and manufacturing operations where material purity is crucial. The systems are designed with adjustable sensitivity settings to accommodate different types of plastic materials and varying levels of metal contamination. Modern plastic metal separators feature automated cleaning mechanisms, digital control interfaces, and real-time monitoring capabilities to optimize operational efficiency. The manufacturers also integrate safety features and compliance measures to meet international standards and regulations. These systems play a vital role in maintaining product quality, protecting processing equipment, and supporting sustainable manufacturing practices.