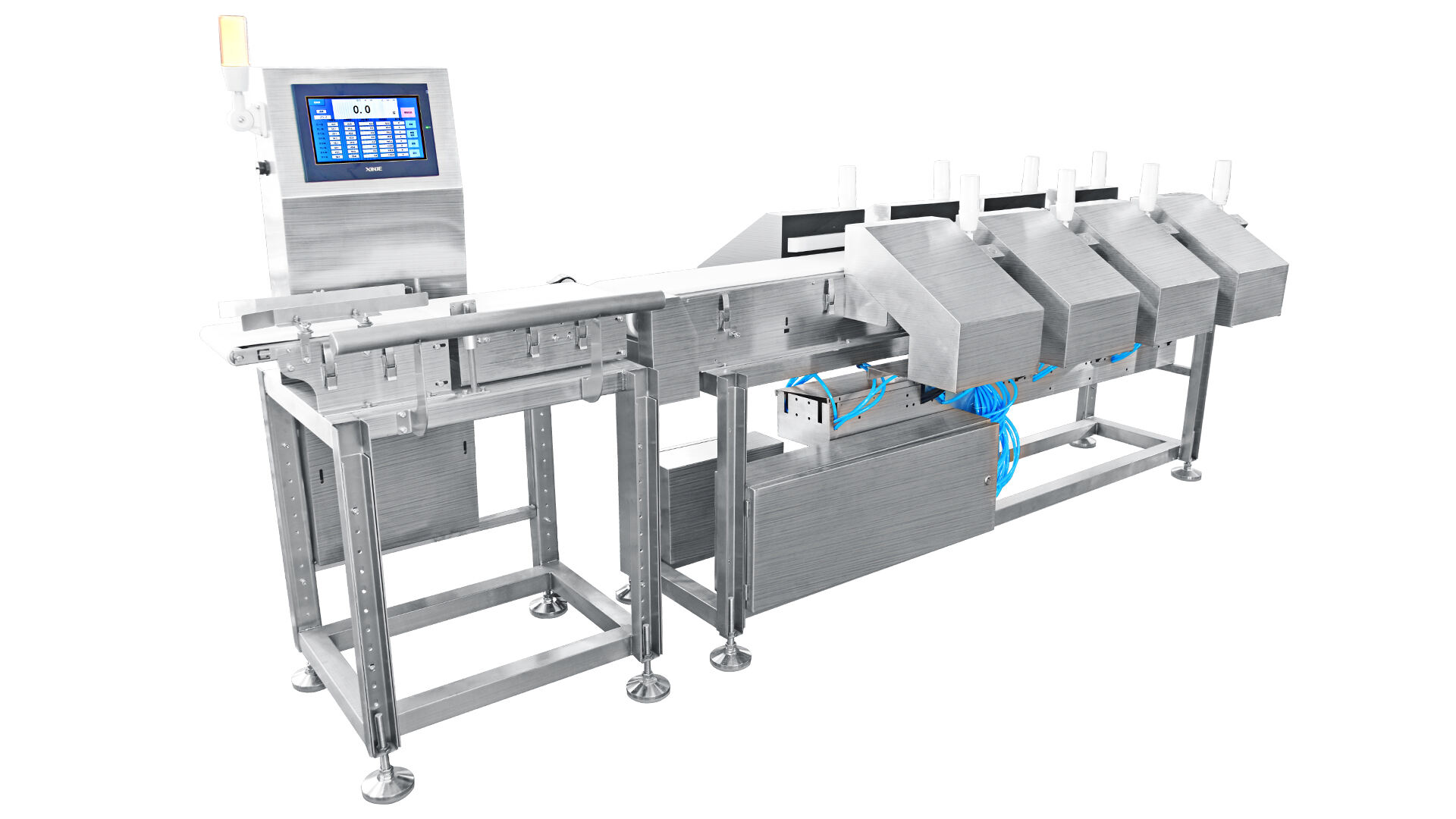

checkweigher conveyor

The checkweigher conveyor represents a cutting-edge solution in automated weight verification systems, designed to ensure precise product weight measurements while maintaining efficient production flow. This sophisticated equipment combines advanced weighing technology with smooth conveyor operations to accurately measure and verify product weights at high speeds. The system features precision load cells that provide real-time weight data, while the conveyor belt ensures consistent product spacing and optimal weighing conditions. The checkweigher conveyor's integration capabilities allow it to seamlessly connect with existing production lines, making it an invaluable tool for quality control and compliance. Its robust construction includes stainless steel components for durability and easy cleaning, while the modular design enables quick maintenance and customization. The system's advanced controls allow for automatic rejection of products that fall outside specified weight parameters, ensuring only compliant items reach the end consumer. Modern checkweigher conveyors also incorporate smart features such as data logging, statistical analysis, and remote monitoring capabilities, enabling manufacturers to optimize their processes and maintain detailed production records.