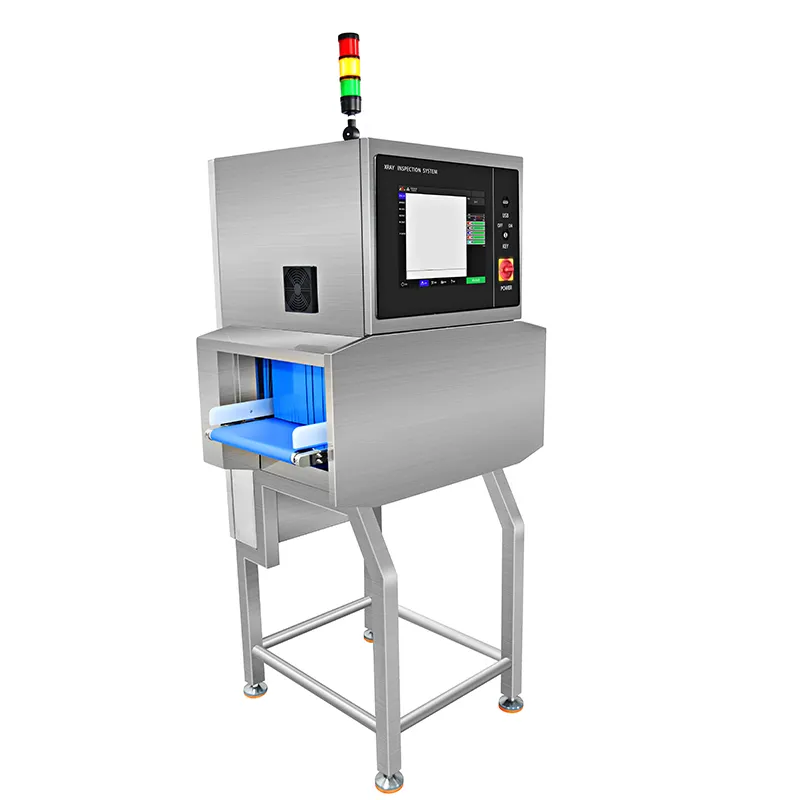

intelligent food x ray system

The intelligent food x ray system represents a cutting-edge solution in food safety inspection and quality control. This advanced technology utilizes high-precision x ray imaging combined with artificial intelligence to detect contaminants, inspect product integrity, and ensure compliance with safety standards. The system operates by generating detailed internal images of food products as they move through the production line, capable of identifying foreign objects as small as 0.3mm in size. Its intelligent algorithms can automatically detect and classify various contaminants including metal, glass, stone, plastic, and bone fragments. The technology also performs comprehensive quality checks, measuring product density, identifying missing components, and verifying fill levels in packaged products. The system features a user-friendly interface that allows operators to set inspection parameters and receive real-time alerts when issues are detected. Advanced data analytics capabilities enable tracking of inspection results, generation of detailed reports, and integration with existing quality management systems. The technology finds applications across various food industry sectors, including meat processing, bakery products, ready-meals, dairy products, and beverages, operating at high throughput speeds while maintaining exceptional detection accuracy.