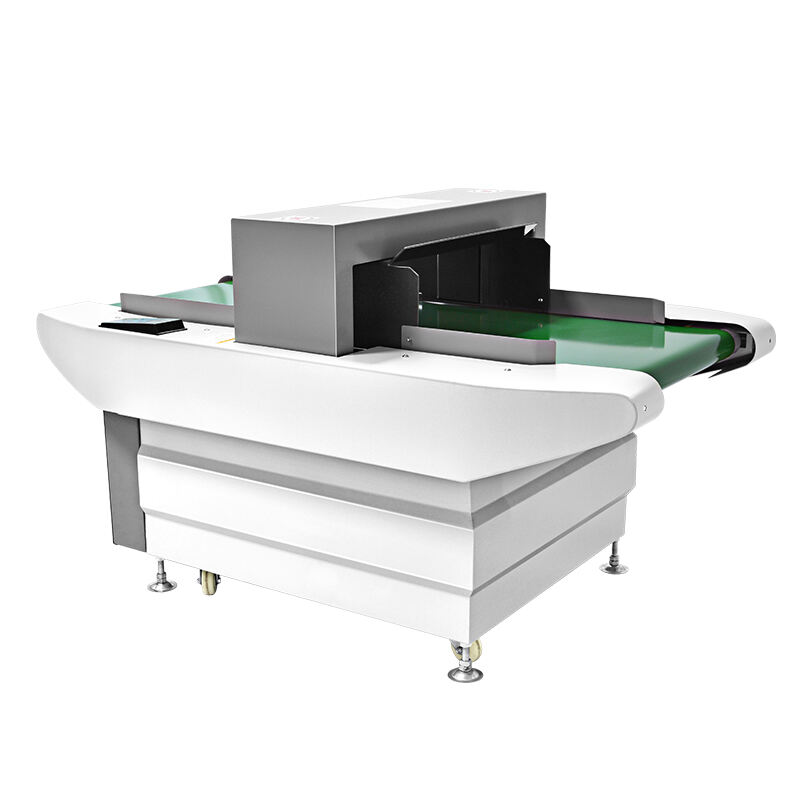

x ray food detector

X-ray food detectors represent a crucial advancement in food safety technology, combining sophisticated imaging capabilities with precise detection mechanisms to ensure product quality and consumer safety. These systems utilize advanced X-ray technology to penetrate food products and packaging, creating detailed images that reveal potential contamination or quality issues. The detector's primary function is to identify foreign objects such as metal fragments, glass pieces, stones, dense plastic, and bone fragments that might contaminate food products during processing. Operating on a continuous basis, these systems can inspect hundreds of products per minute without disrupting production flow. The technology employs varying levels of X-ray energy to detect density differences within products, enabling it to identify contaminants that traditional metal detectors might miss. Modern x-ray food detectors feature high-resolution imaging systems, automated rejection mechanisms, and sophisticated software that can analyze multiple product characteristics simultaneously. They can verify product completeness, check fill levels, identify missing or broken products, and ensure proper package sealing, all while maintaining detailed inspection records for quality assurance and regulatory compliance.