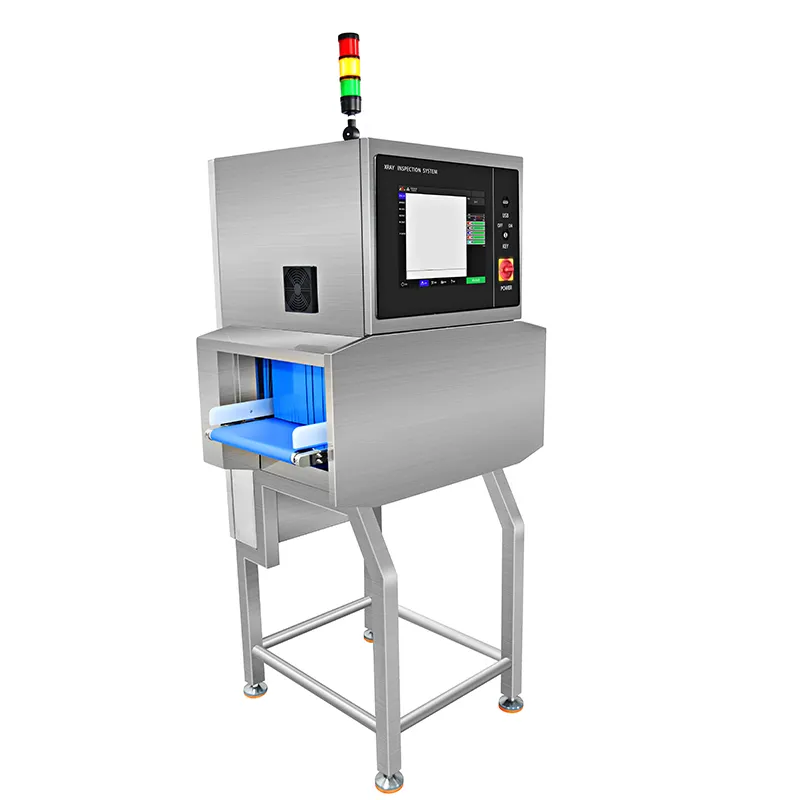

x ray machine for food processing

X-ray machines for food processing represent a critical advancement in food safety and quality control technology. These sophisticated systems use advanced X-ray technology to detect various contaminants and defects in food products during the manufacturing process. The machines operate by emitting low-dose X-ray beams that penetrate food products, creating detailed images that reveal foreign objects, density variations, and product inconsistencies. They can detect metallic and non-metallic contaminants, including glass, stone, bone fragments, and high-density plastics, which might be missed by traditional metal detectors. Modern X-ray inspection systems feature high-resolution imaging capabilities, automated rejection mechanisms, and sophisticated software algorithms that can analyze multiple quality parameters simultaneously. These machines are designed to handle high-speed production lines, processing thousands of products per hour while maintaining consistent inspection accuracy. They are particularly valuable in applications requiring inspection of products in metallized packaging or those packaged in foil containers, where traditional metal detection systems may be ineffective. The technology also enables manufacturers to perform quality checks such as fill-level monitoring, mass measurement, and component counting, all while maintaining compliance with food safety regulations and standards.