small weight checked conveyor supplier

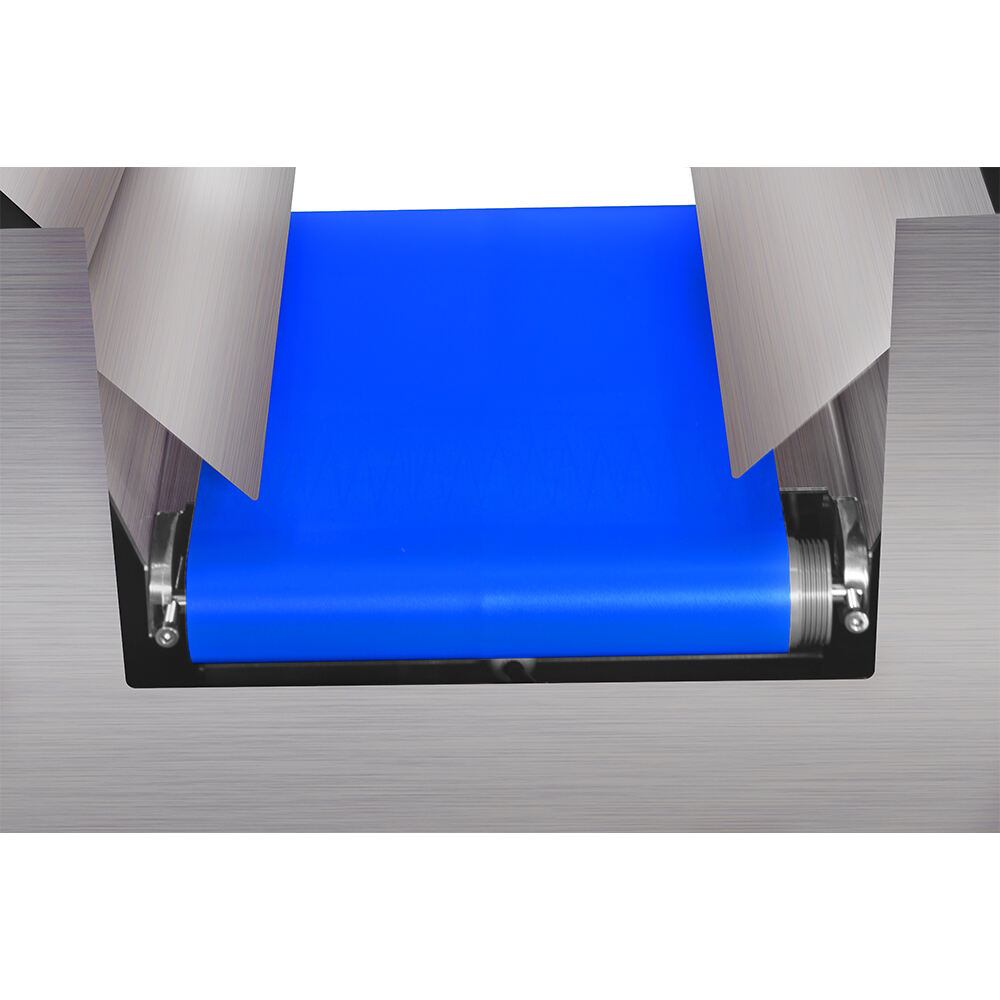

A small weight checked conveyor supplier specializes in delivering precision-engineered conveyor systems designed specifically for weight verification and quality control applications. These systems integrate advanced load cell technology with reliable conveyor mechanisms to ensure accurate weight measurements while maintaining efficient product flow. The equipment typically features high-precision scales capable of measuring items ranging from a few grams to several kilograms, with accuracy levels meeting industry standards. The systems incorporate smart rejection mechanisms that automatically remove products that don't meet specified weight parameters, ensuring quality control standards are maintained. Modern small weight checked conveyors come equipped with user-friendly interfaces, allowing operators to easily set weight parameters, monitor performance metrics, and generate detailed reports. These systems are particularly valuable in food processing, pharmaceutical manufacturing, and packaging industries where weight accuracy is crucial. The conveyors are designed with hygiene in mind, featuring stainless steel construction and easy-to-clean surfaces that comply with food safety regulations. They also include advanced features such as data logging capabilities, remote monitoring options, and integration possibilities with existing production management systems.