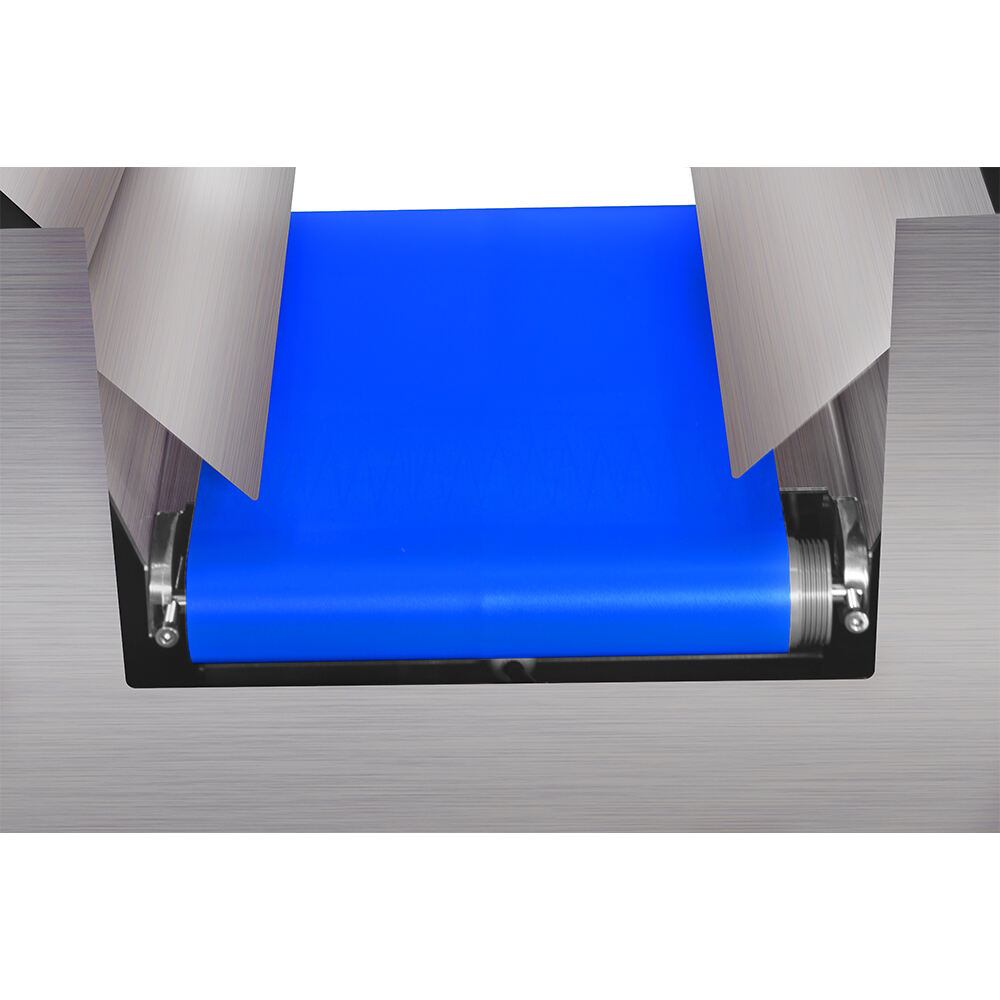

checked conveyor

The checked conveyor represents a sophisticated material handling solution designed to ensure quality control and efficient product transportation. This innovative system incorporates advanced scanning technology that systematically examines items as they move along the conveyor belt, identifying defects, inconsistencies, or irregularities in real-time. Featuring high-resolution cameras and sensors strategically positioned along the belt, the checked conveyor can detect variations in size, shape, color, and surface quality. The system operates at optimized speeds while maintaining precise inspection accuracy, making it ideal for manufacturing, food processing, pharmaceutical, and packaging industries. Integration capabilities with existing production lines allow for seamless implementation, while its modular design facilitates easy maintenance and upgrades. The conveyor's robust construction ensures reliable performance under continuous operation, while its adjustable parameters accommodate various product specifications and inspection criteria. Advanced data processing capabilities enable instant analysis and reporting, supporting quality management systems and regulatory compliance requirements.