| modell |

YW-807 |

| 4010 |

4012 |

4015 |

4020 |

4025 |

4030 |

4035 |

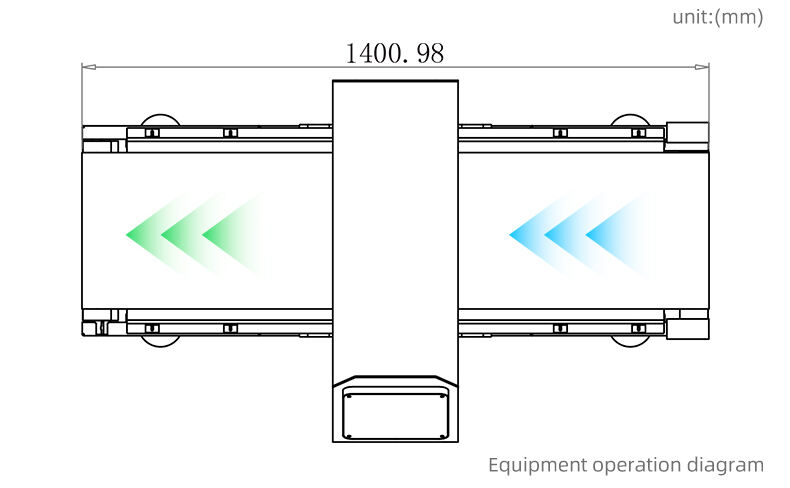

| Erkennungskanalbreite (mm) |

400(anpassbare Breite 200-2000) |

| Detektionskanalhöhe (фmm) |

Konventionelles Maschinenfenster |

Nicht standardisiertes Maschinenfenster |

| 100 |

120 |

150 |

200 |

250 |

300 |

350 |

| Empfindlichkeit |

Fe (фmm) |

0.8 |

1.0 |

1.2 |

1.5 |

2.0 |

2.5 |

3.0 |

| Körpermaterial |

Die gesamte Maschine besteht aus Edelstahl 304 |

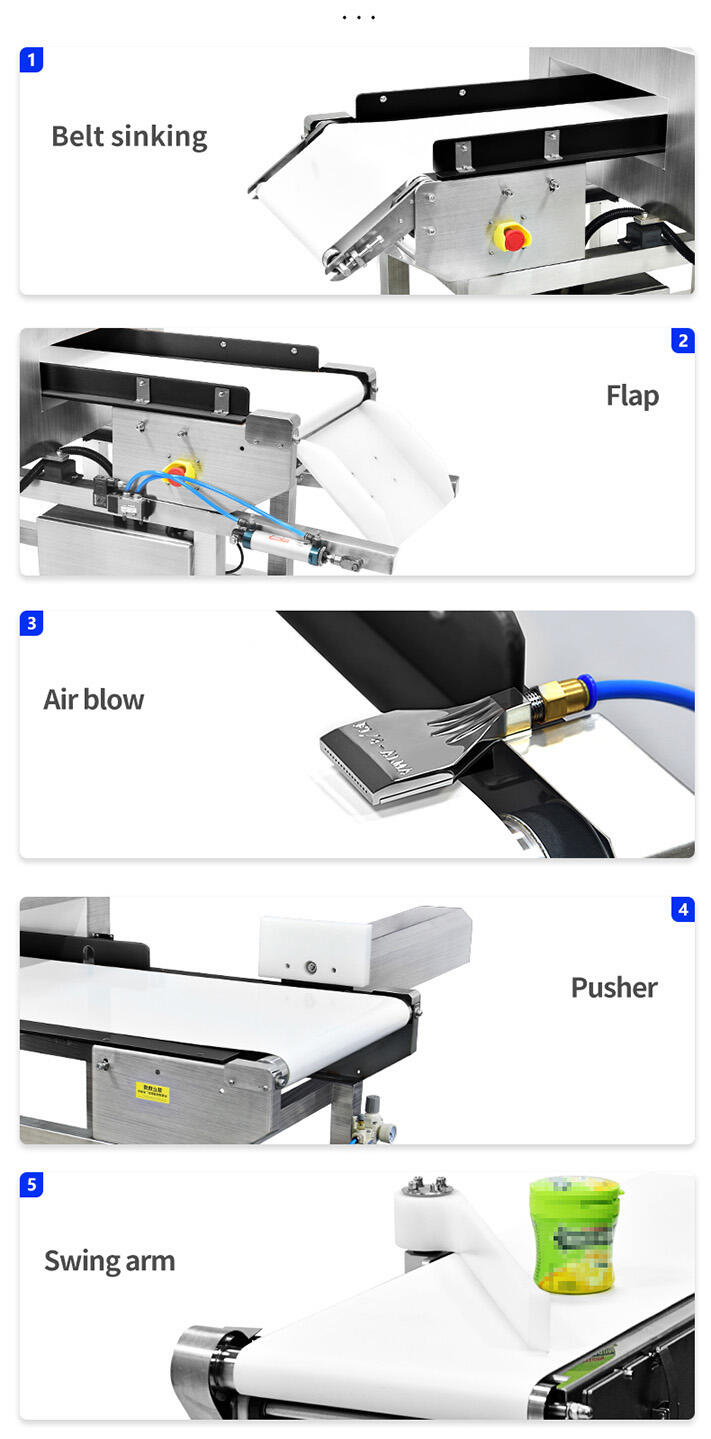

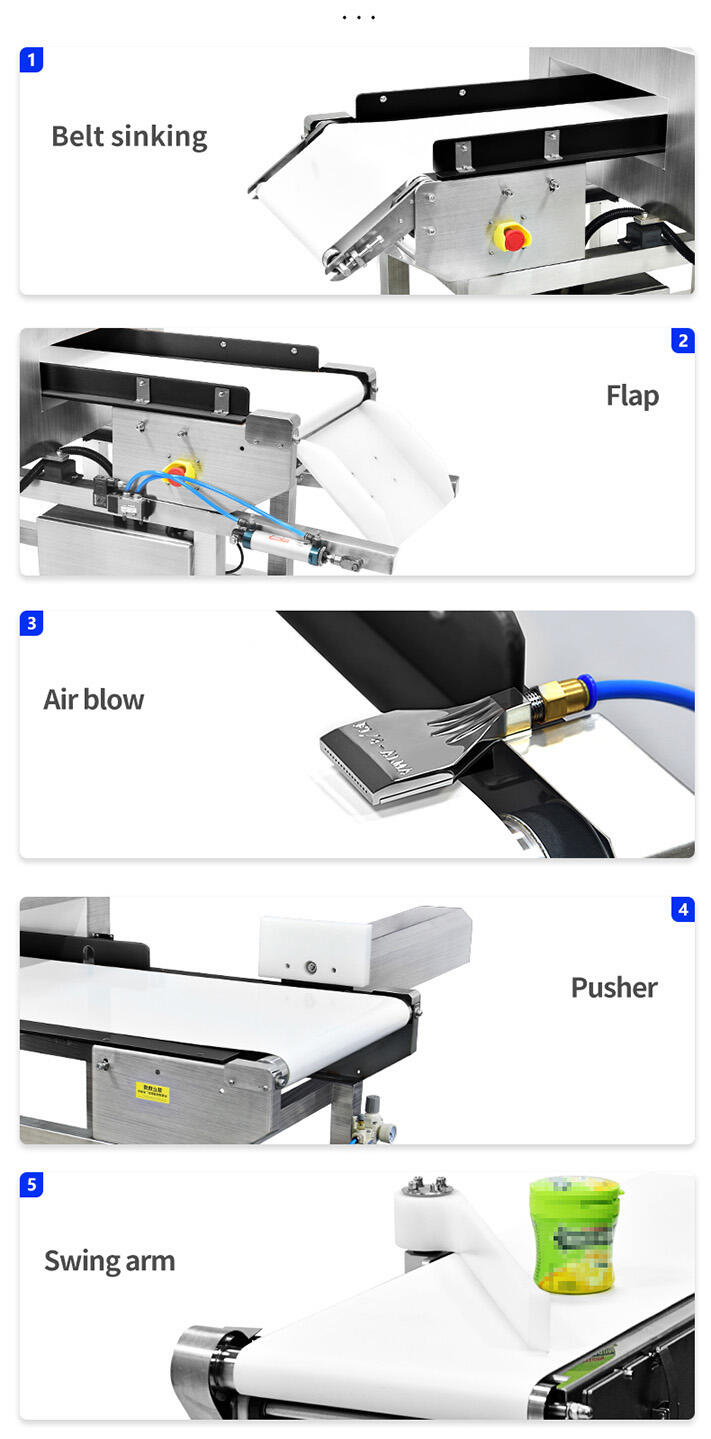

| Alarmmethode |

Automatische Abschaltung bei Erkennung von Fremdstoffen,

und Ausgabe eines 12-V-Summer-Alarmsignals (anpassbar: Klappe, Luft)

blasen, Schubkolben, Schwinge, Absenkung.) |

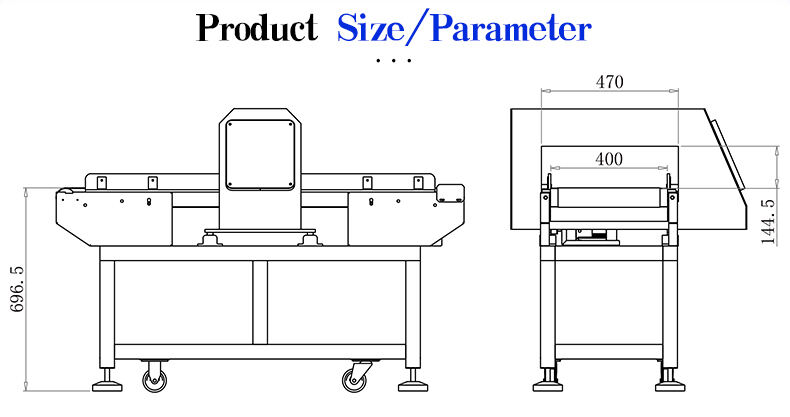

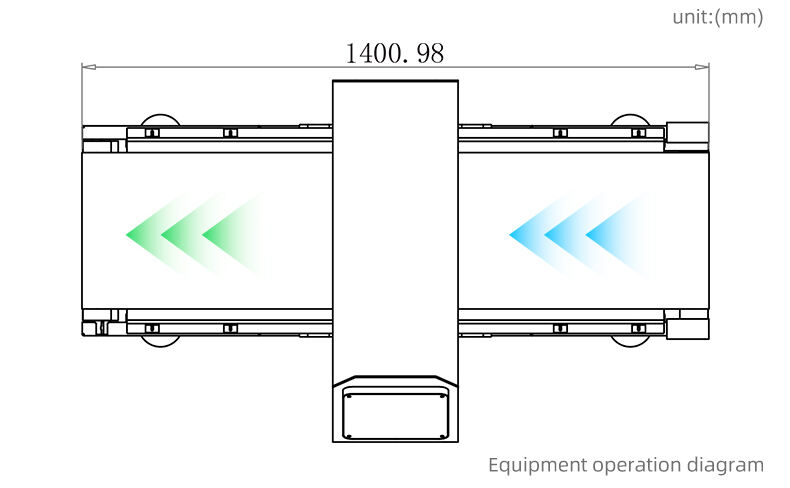

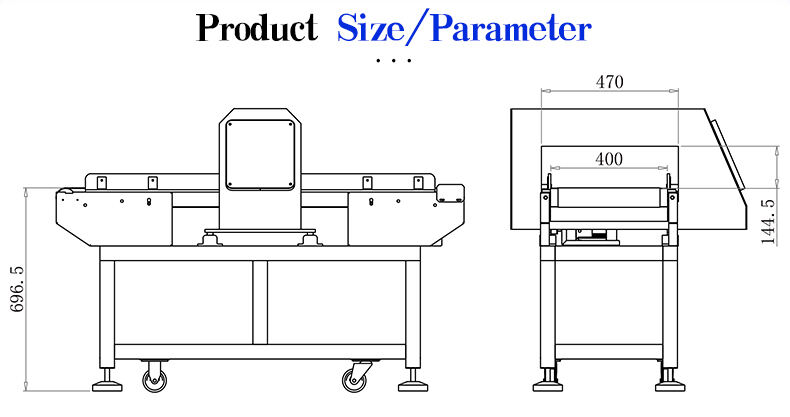

| Maschinengröße |

(L:1400 *B:790*H:790) beachten Sie bitte das Originalprodukt

für die Größe des kundenspezifischen Produkts |

| Maschinengewicht |

≈180KG |

| Leistung |

Stromversorgung: 220 V 50 Hz Leistung: 120 W |

| Wiegekapazität |

<10 kg Geschwindigkeit: 25~30 m/min (nicht einstellbar) |

| Arbeitstisch |

Höhe: 700 mm (anpassbare Höhe) |

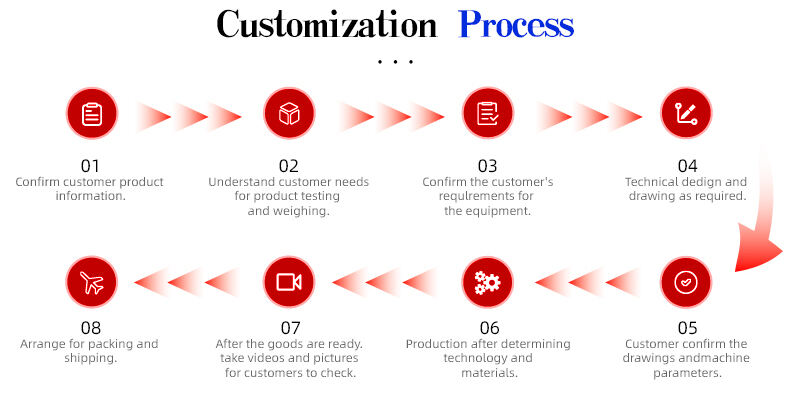

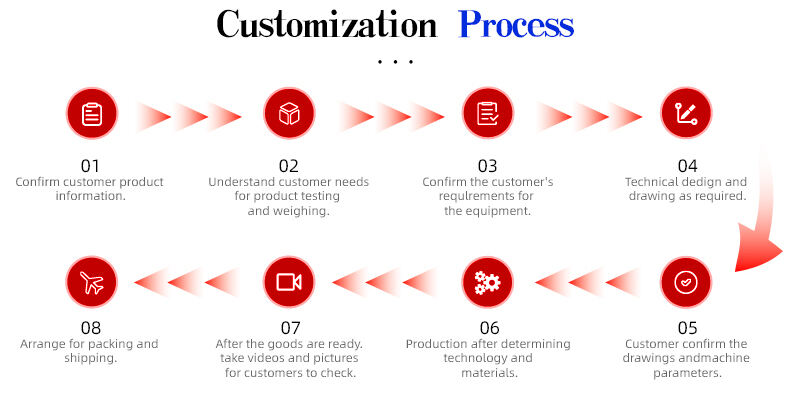

Maschine fertig produkte

Produktgröße/Parameter

Anpassbar Ablehnungssystem

FAQ

A1 : Die Erkennungsgenauigkeit (Empfindlichkeit) der Anlage hängt von der Produktöffnung, den Materialeigenschaften und der Art des Metalls ab. Zum Beispiel

bei allgemeinen Lebensmitteln oder Kunststoffpellets können unsere hochsensiblen Modelle metallische Kugeln mit einem Durchmesser von 0,3 mm bis 0,8 mm .

Stabil erkennen. Wir empfehlen, dass Sie eine geringe Anzahl von Proben bereitstellen, und wir ermitteln die genaue Erkennungsgenauigkeit für Sie durch kostenloses Probestellen und stellen einen Prüfbericht aus.

A2 : Absolut. Unsere Metalldetektoren sind mit einer IP54 oder höher schutzklasse, die hervorragenden Schutz vor Staub und Wasser bietet.

Inzwischen verwendet der Kern der Ausrüstung fortschrittliche digitalsignalverarbeitungstechnologie und automatisches Phasenfolgesystem funktionen,

die Umgebungsstörungen und Produkteinflüsse (z. B. feuchte und salzhaltige Lebensmittel) effektiv unterdrücken kann, wodurch auch in rauen industriellen Umgebungen eine hohe Stabilität und Zuverlässigkeit gewährleistet ist.

A3 ja. Wir verfügen über ein professionelles Konstruktionsteam und können anpassungsdienste anpassungen anbieten, einschließlich nichtstandardmäßiger Öffnungen, spezieller Förderbänder (z. B. PU, Teflon),

unterschiedliche Materialien (z. B. Edelstahl 304) sowie integrierte Ausschleuseinrichtungen (z. B. Klappe, Stoßstange, Luftstrahl).

Bitte geben Sie Ihren spezifischen Aufbau Ihrer Produktionslinie und Ihre Anforderungen an, damit wir eine maßgeschneiderte Lösung für Ihre Bedürfnisse erstellen können.

A4 : Wir versprechen, bereitzustellen 24/7 Online-Technikberatung . Bei allgemeinen Problemen garantieren wir eine Antwort innerhalb von 2 Stunden

bei Notfällen bieten wir eine Ferndiagnose an. Wenn das Problem nicht fernmündlich gelöst werden kann,

werden wir je nach Situation die Entsendung von Ingenieuren für vor-Ort-Dienstleistungen organisieren, um sicherzustellen, dass Ihre Ausfallzeit minimiert wird.